A method for controlling the microstructure of q345b thick slab

A control method and billet technology, applied in the field of Q345B thick slab structure control, can solve problems such as staying in the experimental stage, and achieve the effects of low implementation difficulty, simple process and improved steel performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The casting speed of the billet is 1.3m / min, and the surface structure of the planed continuous casting billet is bainite + martensite. The corresponding cooling water distribution Q of each section of the continuous casting machine is shown in Table 1.

[0024]

[0025]

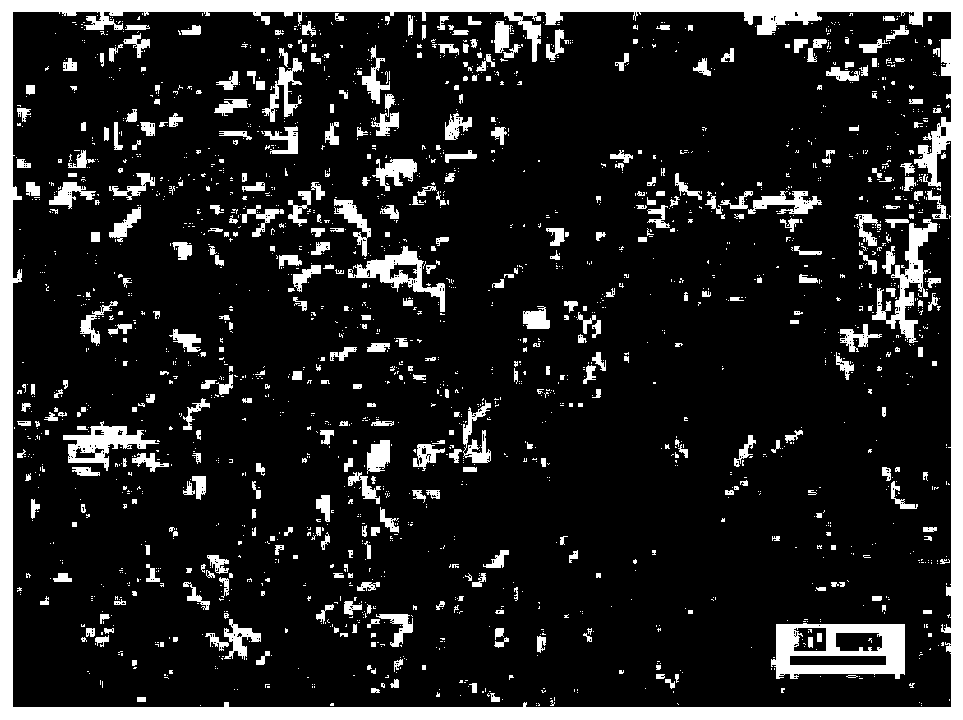

[0026] After the continuous casting slab was off-line, samples were taken from the surface layer of the slab, processed, polished and corroded, and observed under a metallographic microscope. The results were as follows: figure 1 As shown, its surface structure is bainite + martensite.

Embodiment 2

[0028] The casting speed of the billet is 1.4m / min, and the surface structure of the planed continuous casting billet is ferrite+pearlite+bainite. The corresponding cooling water distribution Q of each section of the continuous casting machine is shown in Table 1.

[0029] Caster location Q l / min Caster location Q l / min section 300 Seven paragraphs 矫直

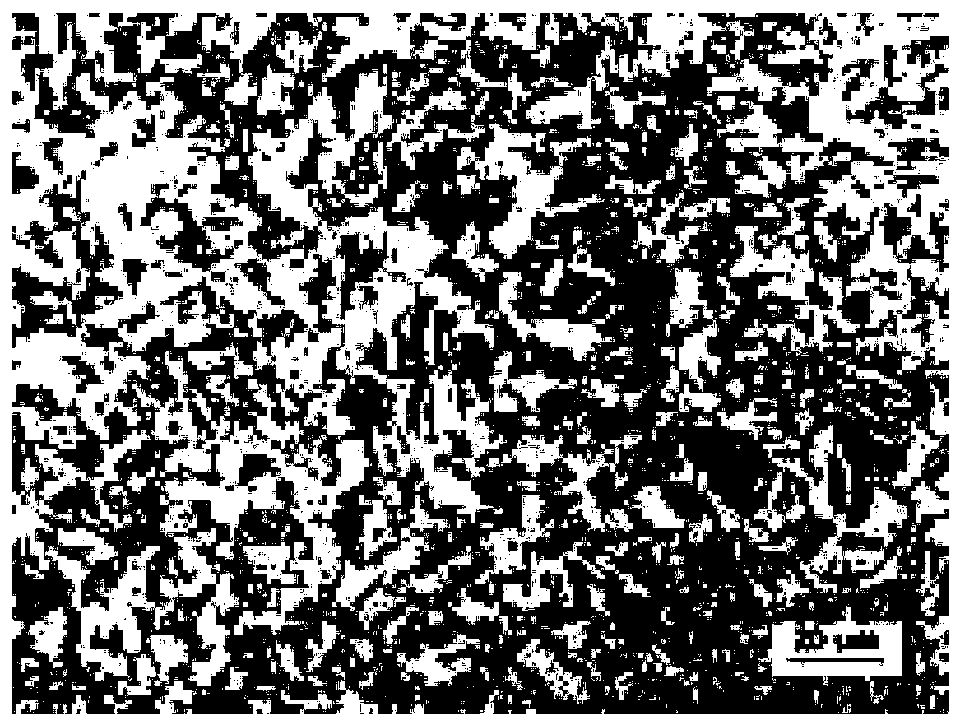

[0030] After the continuous casting slab was off-line, samples were taken from the surface layer of the slab, processed, polished and corroded, and observed under a metallographic microscope. The results were as follows: figure 2 As shown, its surface structure is ferrite + pearlite + bainite.

Embodiment 3

[0032] The slab casting speed is 1.4m / min, and the surface structure of the planned continuous casting slab is ferrite + pearlite after it goes off the production line. The corresponding cooling water distribution Q of each section of the continuous casting machine is shown in Table 1.

[0033] Caster location Q l / min Caster location Q l / min section 300 Seven paragraphs 矫直

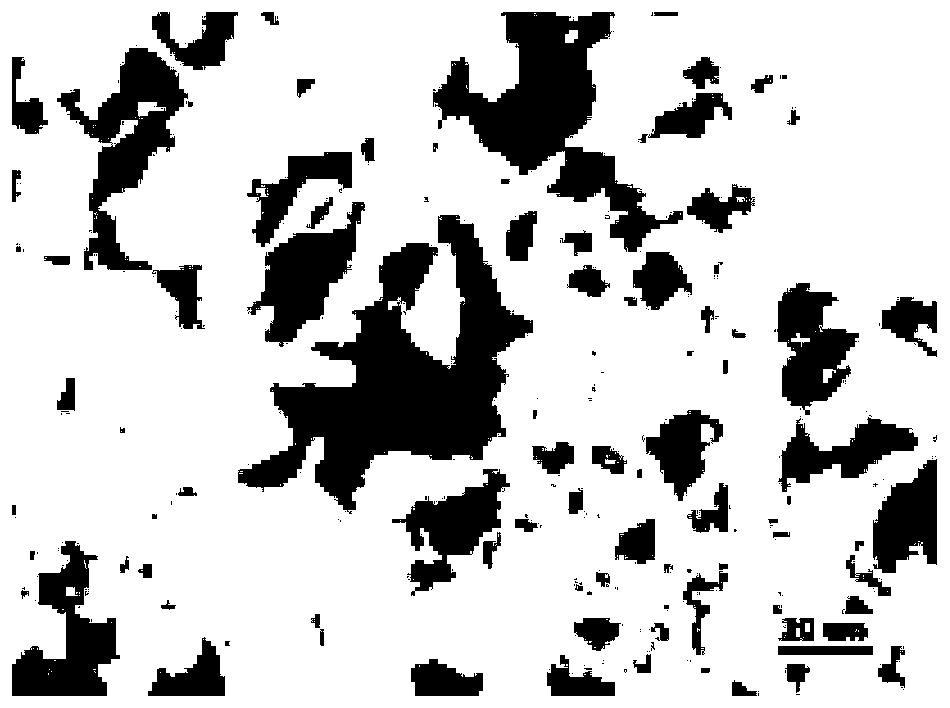

[0034] After the continuous casting slab was off-line, samples were taken from the surface layer of the slab, processed, polished and corroded, and observed under a metallographic microscope. The results were as follows: image 3 As shown, its surface structure is ferrite + pearlite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com