A kind of graphitization method of isostatic graphite product

A technology of graphite products and graphitization, which is applied in the field of graphite material preparation, can solve problems such as improvement of cracks in Acheson graphitization products, achieve the effects of increasing product quality, reducing the occurrence of transverse cracks, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

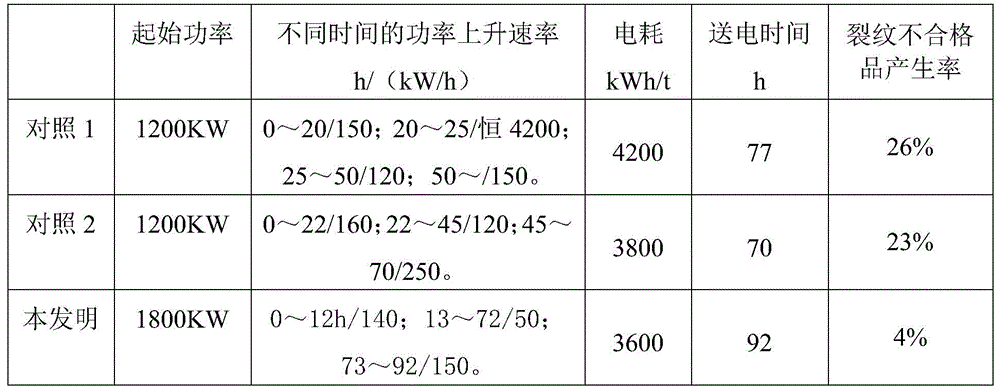

Examples

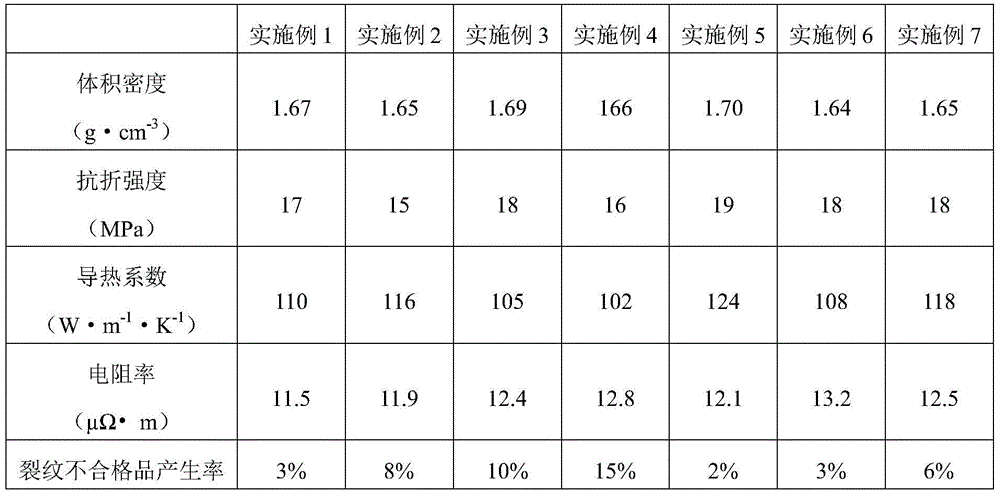

Embodiment 1

[0052] 1) Clean up the graphitization furnace;

[0053] 2) On the bottom of the furnace body of the cleaned graphitization furnace, lay flat and compacted quartz sand with a thickness of 500 mm; , the thickness is 400mm;

[0054] 3) Then pave and compact the metallurgical material obtained by uniformly mixing cooked metallurgical coke and raw metallurgical coke in a mass ratio of 7:3; then pave and compact new coke powder and quartz sand in a mass ratio of 5.5:4.5 The reaction material obtained by mixing uniformly; wherein, the particle size of the cooked metallurgical coke is 10-40mm, and its particle size distribution is: 10% by mass of the particle size of 10-15mm, 10% by mass of 35-40mm, and the balance It is cooked metallurgical coke with a particle size of 15-35mm;

[0055] 4) Make the same cross-section of the same specification as 1800cm 2 The product is placed in the furnace, which is symmetrical to the furnace core, and a 30mm gap is reserved between the products ...

Embodiment 2

[0062] 1) Clean up the graphitization furnace;

[0063] 2) On the bottom of the furnace body of the cleaned graphitization furnace, lay flat and compacted quartz sand with a thickness of 500 mm; , the thickness is 400mm;

[0064] 3) Then pave and compact the metallurgical material obtained by uniformly mixing cooked metallurgical coke and raw metallurgical coke in a mass ratio of 6:4; then pave and compact new coke powder and quartz sand in a mass ratio of 5.5:4.5 The reaction material obtained by mixing uniformly; wherein, the particle size of the cooked metallurgical coke is 10-40mm, and its particle size distribution is: 15% by mass of the particle size of 10-15mm, 15% by mass of 35-40mm, and the balance It is cooked metallurgical coke with a particle size of 15-35mm;

[0065] 4) The same section of the same specification is 1500cm 2 The product is placed in the furnace, which is symmetrical to the furnace core, and a 30mm gap is reserved between the products to prepare ...

Embodiment 3

[0072] 1) Clean up the graphitization furnace;

[0073] 2) On the bottom of the furnace body of the cleaned graphitization furnace, lay flat and compacted quartz sand with a thickness of 500 mm; , the thickness is 400mm;

[0074] 3) Then pave and compact the metallurgical material obtained by uniformly mixing cooked metallurgical coke and raw metallurgical coke in a mass ratio of 8:2; then pave and compact new coke powder and quartz sand in a mass ratio of 5.5:4.5 The reaction material obtained by mixing uniformly; wherein, the particle size of the cooked metallurgical coke is 10-40mm, and its particle size distribution is: the mass percentage of the particle size is 10-15mm, 10%, the mass percentage of 35-40mm is 15%, and the balance It is cooked metallurgical coke with a particle size of 15-35mm;

[0075] 4) Make the same cross section of the same specification 1000cm 2 The product is placed in the furnace, which is symmetrical to the furnace core, and a 30mm gap is reser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com