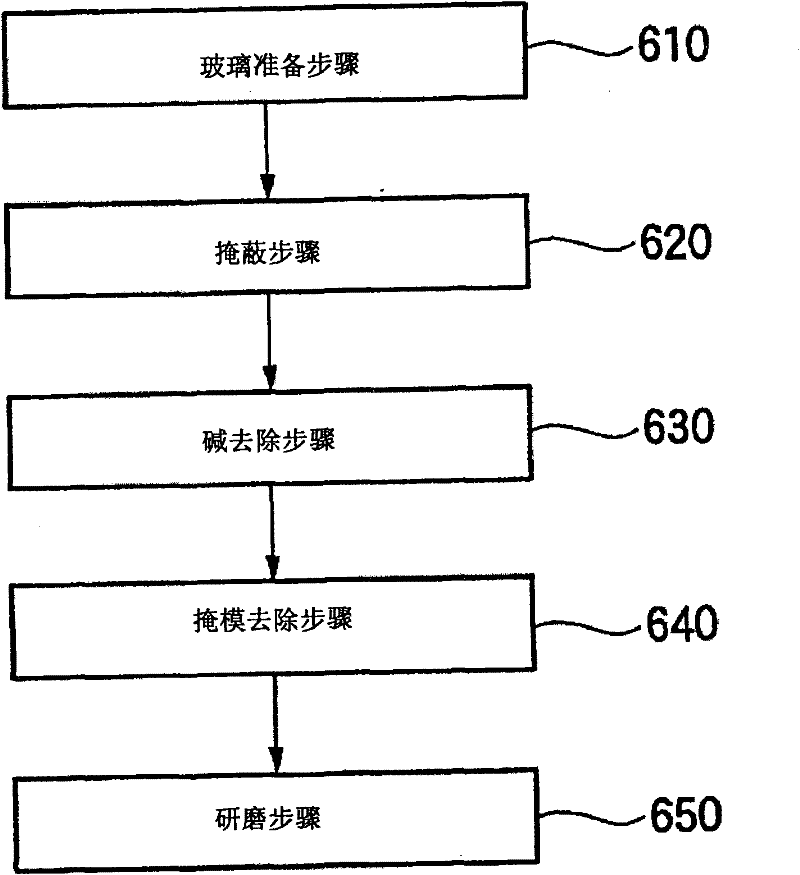

Method of glass surface fine processing

A microfabrication and glass surface technology, which is applied to the photoplate-making process of the patterned surface, metal processing equipment, and machine tools suitable for grinding workpiece planes, etc., can solve the problems of difficult and effective mechanical mirror finishing, and achieve the reduction of cracks and The effect of the appearance of transverse cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

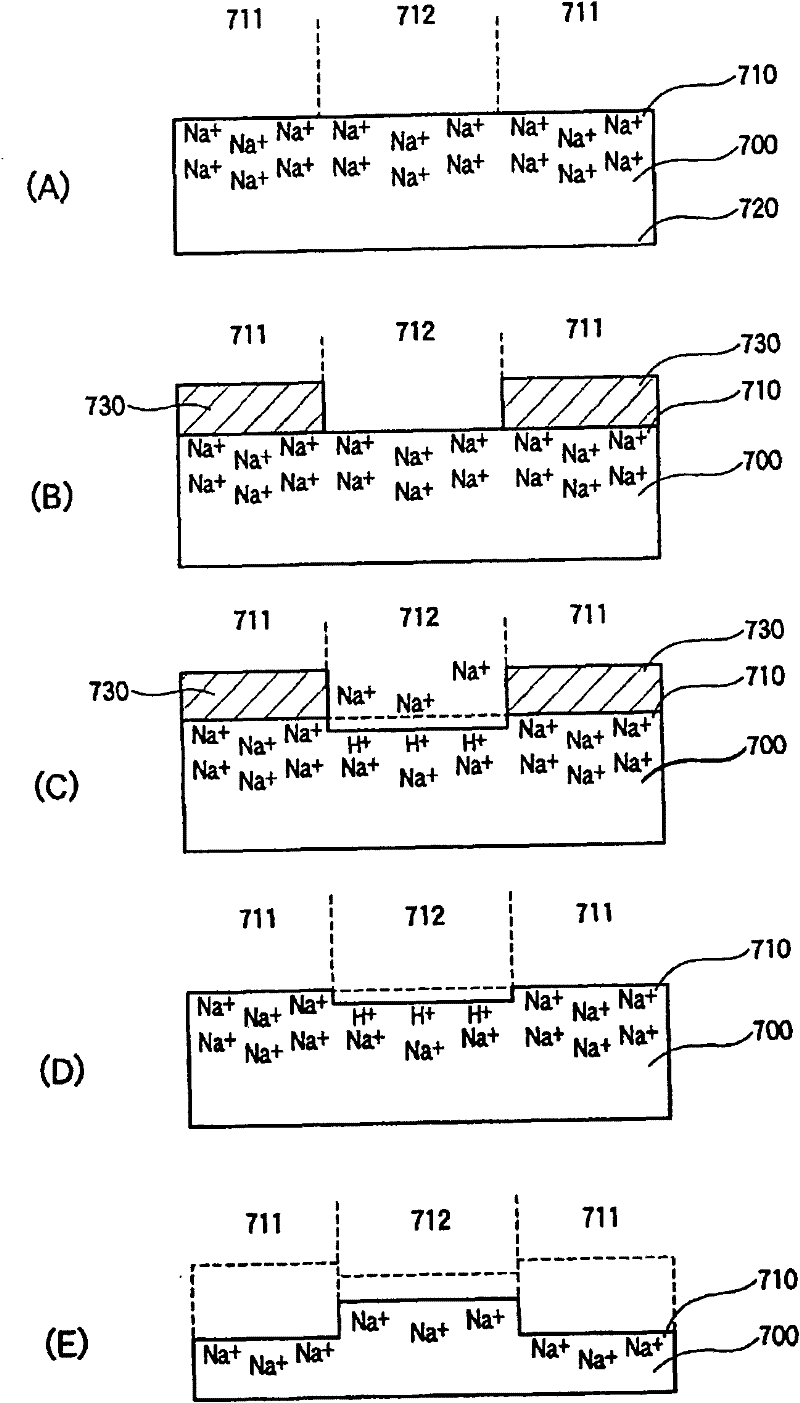

[0078] First, aluminum lithium silicate glass is prepared as glass. The glass is ground with a ceria slurry or a colloidal silica slurry in order to obtain an average surface roughness below 10 nm.

[0079] Subsequently, mask the given area with Kapton tape.

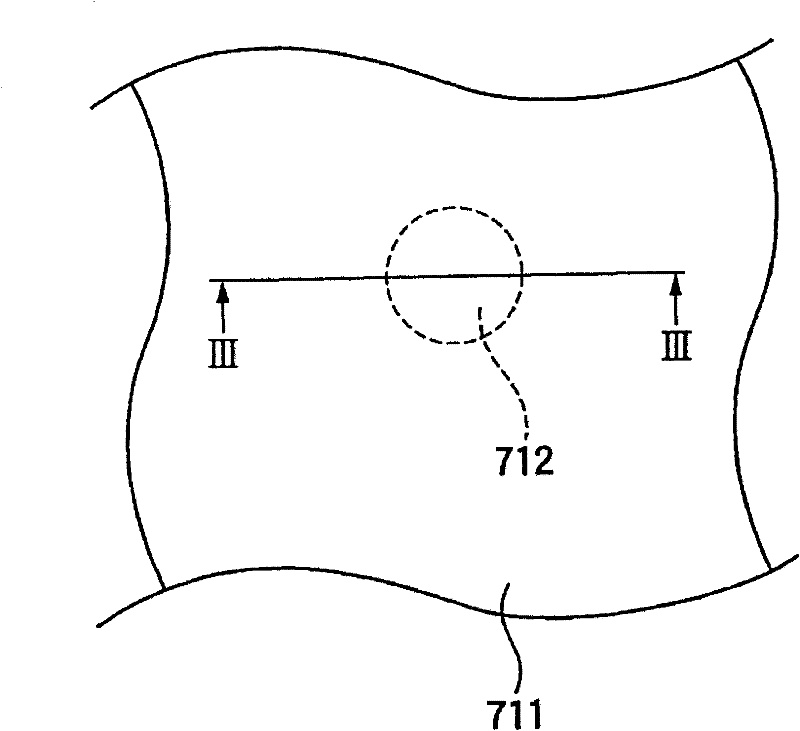

[0080] The glass was then immersed in an aqueous solution of nitric acid adjusted to a pH of 2 for 30 minutes at room temperature. Thus, the alkali removal process is performed on the area not covered with the mask. In the region not covered with the mask (the region subjected to the alkali removal treatment), alkali ions diffuse out from the region near the glass surface, and the surface is slightly etched. As a result, the region subjected to the alkali removal treatment becomes to have a smaller glass thickness than the masked region (region not subjected to the alkali removal treatment) in terms of the glass thickness measured from the back surface of the glass. The glass thickness in the region where the alkali r...

Embodiment 2

[0084] The same glass as in Example 1 was prepared, and an area in the glass was covered with Kapton tape in the same manner as in Example 1.

[0085] Subsequently, the glass was immersed in an aqueous solution of nitric acid adjusted to pH 2 for 30 minutes. The impregnation was carried out at 40° C. different from that in Example 1. Thus, the alkali removal process is performed on the area not covered with the mask. As in Example 1, in the region where the alkali removal treatment was performed, alkali ions diffused from the region near the glass surface, and the surface was slightly corroded. As a result, the glass thickness in the region where the alkali removal treatment had been performed was different from that in the region where the alkali removal treatment had not been performed by 30 nm.

[0086] The Kapton tape was then peeled off as in Example 1.

[0087] Subsequently, as in Example 1, the glass was ground using a colloidal silica slurry. This milling was perfo...

Embodiment 3

[0089] In the alkali removal treatment, the relationship between leaching, in particular where glass is immersed in an acidic solution, and glass composition, immersion time, temperature, and pH value was examined.

[0090] First, four kinds of glasses having various compositions shown in Table 1 were prepared. In Table 1, the compositions are shown in mol%.

[0091] Table 1

[0092] Glass

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com