Sandwich structure bulletproof ceramic sheet and low temperature sintering preparation method

A ceramic chip and sandwich technology, which is applied in the field of protective materials and hard bulletproof materials, can solve the problems of high cost and complicated process, and achieve the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

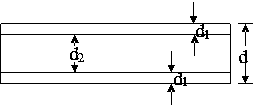

[0025] A bullet-proof ceramic sheet with a sandwich structure is characterized in that the components of the upper and lower surface layers of the bullet-proof ceramic sheet with a sandwich structure are 95% Al by mass percentage 2 o 3 +5%ZrO 2 , the composition of the center layer is 85% Al by mass percentage 2 o 3 +15%ZrO 2 The thickness ratio of the surface layer and the center layer of the bullet-proof ceramic sheet of sandwich structure after sintering is 1:12; 50mm, thickness 10mm; after sintering, the relative density of the bulletproof ceramic sheet is 99.5%, the impact toughness is 1.4J, the bending strength is 577MPa, and the fracture toughness is 10.56 MPa m 1 / 2 .

[0026] Its preparation steps are as follows:

[0027] (1) Preparation of composite powder: prepare 95% Al according to mass percentage 2 o 3 +5%ZrO 2 and 85% Al 2 o 3 +15%ZrO 2 Composite powder, mixed by ball mill, dried and ground for later use; where Al 2 o 3 and ZrO 2 The particle sizes...

Embodiment 2

[0033] A bullet-proof ceramic sheet with a sandwich structure is characterized in that the composition of the upper and lower surface layers of the bullet-proof ceramic sheet with a sandwich structure is 85% Al by mass percentage 2 o 3 +15%ZrO 2 , the composition of the center layer is 75% Al by mass percentage 2 o 3 +25%ZrO 2 The thickness ratio of the surface layer and the center layer of the bullet-proof ceramic sheet of sandwich structure after sintering is 1:6; 40mm, thickness 8mm; after sintering, the relative density of the bulletproof ceramic sheet is 98.5%, the impact toughness is 1.0J, the bending strength is 514MPa, and the fracture toughness is 9.88 MPa m 1 / 2 .

[0034] Its preparation steps are as follows:

[0035] (1) Preparation of composite powder: prepare 85% Al according to mass percentage 2 o 3 +15%ZrO 2 and 75% Al 2 o 3 +25%ZrO 2 Composite powder, mixed by ball mill, dried and ground for later use; where Al 2 o 3 and ZrO 2 The particle sizes ...

Embodiment 3

[0041] A bullet-proof ceramic sheet with a sandwich structure is characterized in that the composition of the upper and lower surface layers of the bullet-proof ceramic sheet with a sandwich structure is 90% Al by mass percentage 2 o 3 +10%ZrO 2 , the composition of the center layer is 80% Al by mass percentage 2 o 3 +20%ZrO 2 The thickness ratio of the surface layer and the center layer of the bullet-proof ceramic sheet of the sandwich structure after sintering is 1:10; the surface of the bullet-proof ceramic sheet is a square, and the thickness direction is a sandwich layered structure. After sintering, the square side length is 40mm and the thickness is 10mm; The relative density of the rear bulletproof ceramic sheet is 99%, the impact toughness is 1.2J, the bending strength is 507MPa, and the fracture toughness is 10.44MPa m 1 / 2 .

[0042] Its preparation steps are as follows:

[0043] (1) Preparation of composite powder: prepare 90% Al according to mass percentage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com