Core-spun thread and method for implementing molten steel vanadium-nitrogen alloying

A technology of nitrogen alloying and cored wire, which is applied in the field of nitrogen alloying to realize vanadium in molten steel, can solve the problem of large fluctuations in vanadium recovery rate and nitrogen recovery rate, difficulty in feeding the cored wire through steel slag, Unfavorable vanadium recovery rate and nitrogen recovery rate and other issues, to achieve the effect of improving vanadium recovery rate and nitrogen recovery rate, good fluidity, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

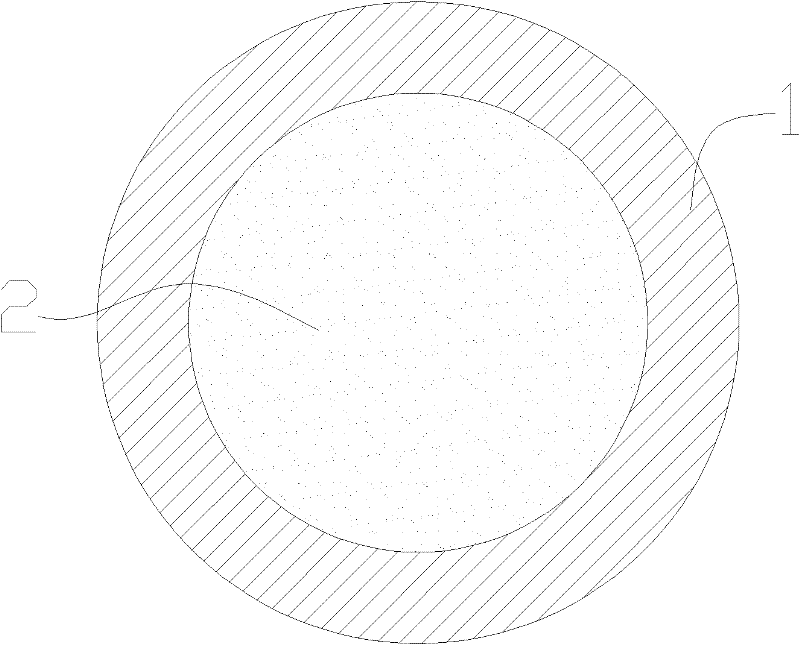

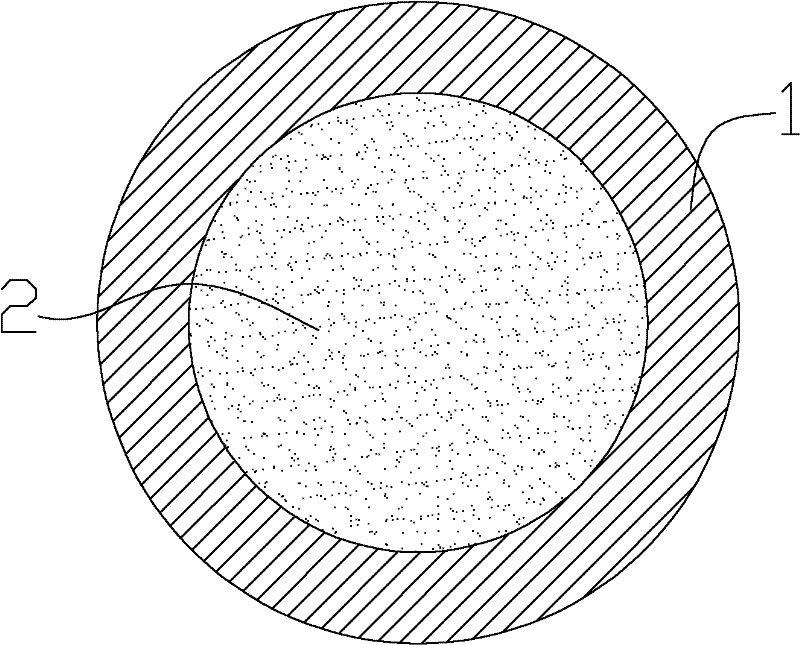

[0036] A cored wire for alloying vanadium and nitrogen in molten steel, including a core layer, the core layer is composed of vanadium nitride alloy and fluorite, and the weight ratio of the vanadium nitride alloy and fluorite is: vanadium nitride Alloy: 85%, fluorite: 15%, both vanadium nitride alloy and fluorite are powder materials, the particle size is less than 3mm, the core layer is wrapped with a sheath made of cold-rolled strip steel, and the outer diameter of the entire cored wire is 12mm.

Embodiment 2

[0038] A cored wire for alloying vanadium and nitrogen in molten steel, including a core layer, the core layer is composed of vanadium nitride alloy and fluorite, and the weight ratio of the vanadium nitride alloy and fluorite is: vanadium nitride Alloy: 95%, fluorite: 5%, both vanadium nitride alloy and fluorite are powder materials, the particle size is less than 3mm, the core layer is wrapped with a sheath made of cold-rolled strip steel, and the outer diameter of the entire cored wire is 12mm.

Embodiment 3

[0040] The cored wire used for alloying molten steel with vanadium and nitrogen includes a core layer, the core layer contains vanadium nitride alloy, fluorite and vanadium-iron alloy, and the weight ratio of the vanadium nitride alloy, fluorite and vanadium-iron alloy is: Vanadium Nitride Alloy: 90%, Fluorite: 5%, Vanadium Iron Alloy: 5%. Vanadium nitride alloy, fluorite and vanadium-iron alloy are all powder materials with a particle size of less than 3mm. The core layer is wrapped with a sheath made of cold-rolled strip steel. The outer diameter of the entire cored wire is 13mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com