Nano Titanium dioxide/fluorite photocataly tic material and preparation process thereof

A nano-titanium dioxide, composite photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of secondary pollution, weak interaction force, difficult separation and purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

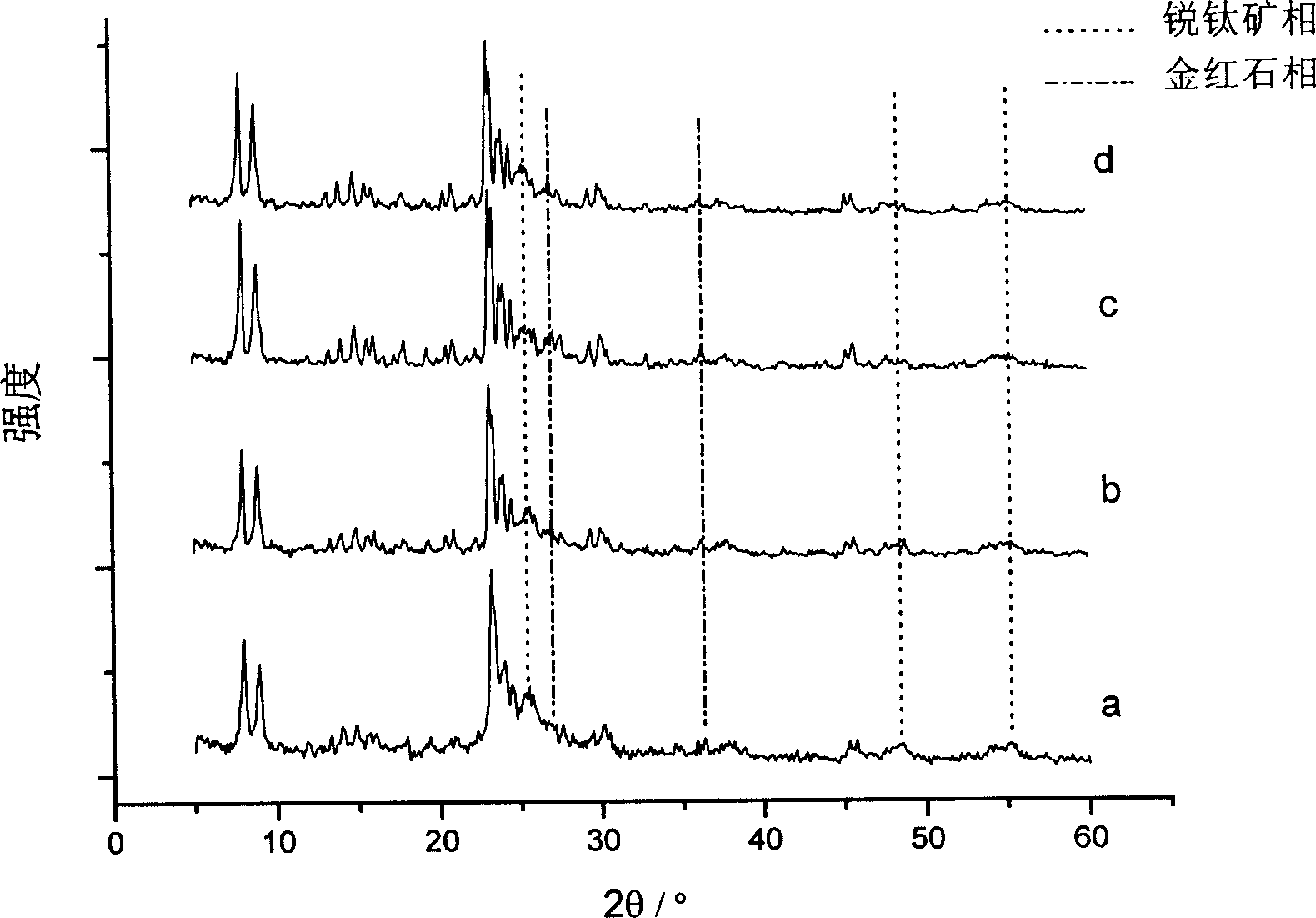

[0020] Embodiment 11: Taking Example 1 as an example, the specific preparation process is as follows: weigh 1g of ZSM-5 zeolite with a silicon-aluminum ratio of 20, add 3ml of 5% dilute ammonia water, stir well and let stand at room temperature for 30min, add 2g TiCl solution (15% ), stir well, dry at 100°C, and bake in a muffle furnace at 550°C for 2h.

Embodiment 12

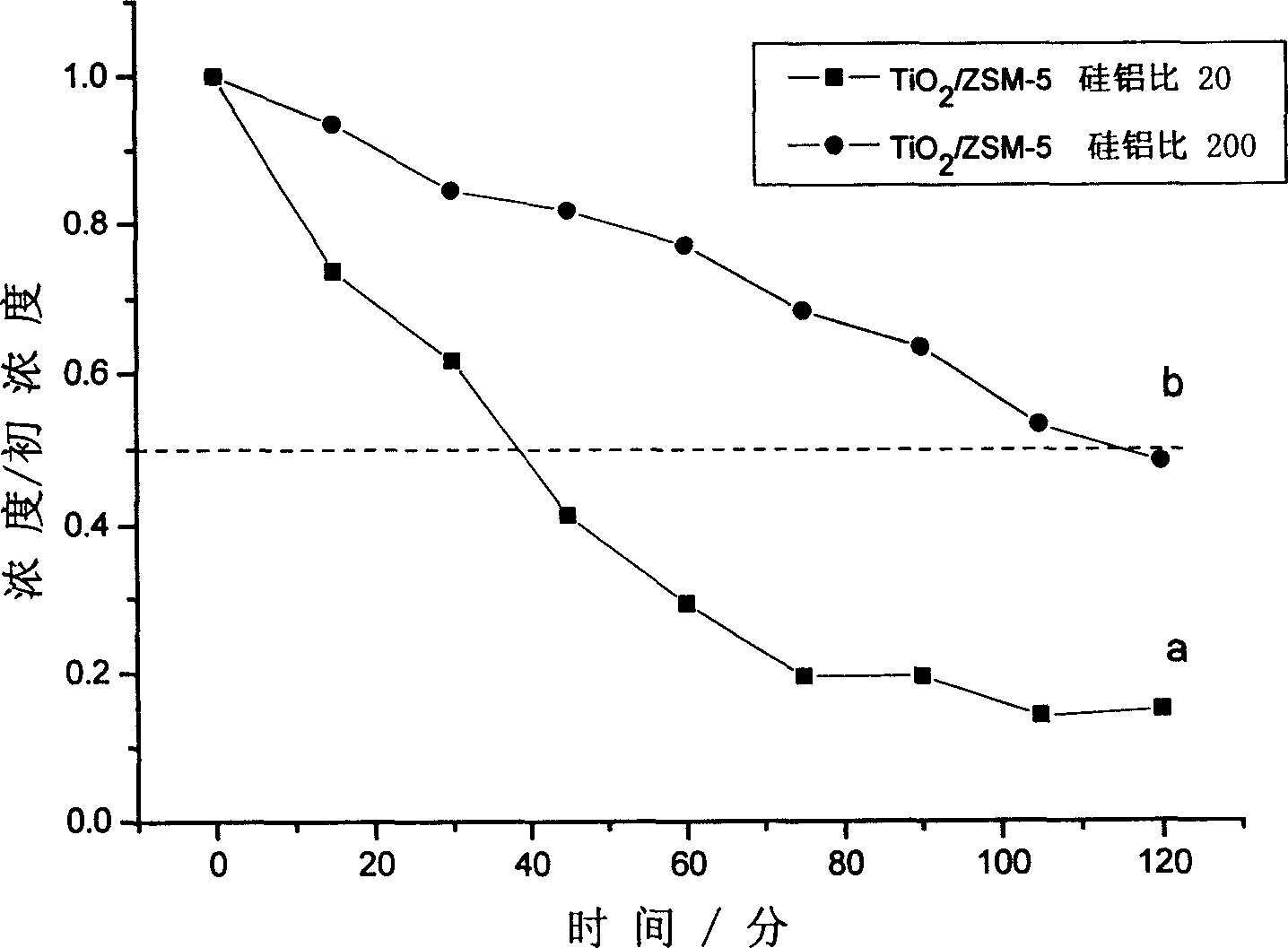

[0021] Example 12: Catalytic reaction of phenol UV self-degradation. Weigh the active material TiO 2 Put 50mg of the corresponding quality composite material in the catalytic reactor, add 100mL of phenol solution with a concentration of 100ppm, stir evenly, keep the temperature at 30°C, and degrade spontaneously under the irradiation of a UV lamp with a main wavelength of 365nm, take samples at regular intervals, and use a UV spectrophotometer at a wavelength of 270nm Detect the residual phenol concentration in the reaction solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com