Method for preventing surface of flexible package lithium-ion battery from being corroded

A lithium-ion battery and flexible packaging technology, which is applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve problems that affect product quality, and the surface is susceptible to corrosion, so as to reduce production costs and prevent surface corrosion , Improve the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

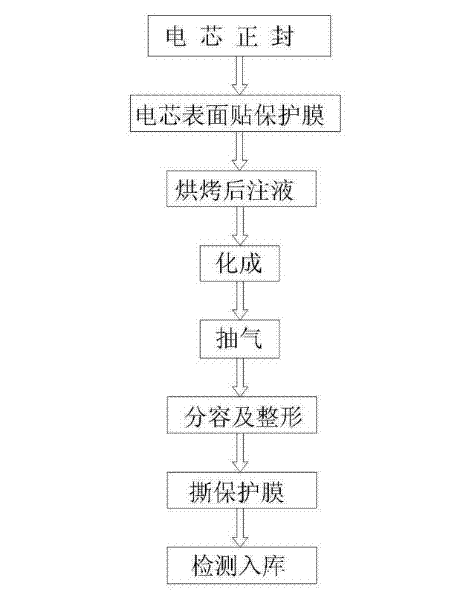

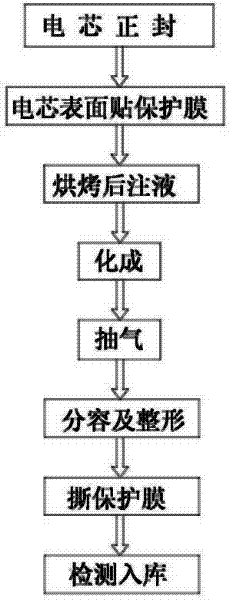

[0019] like figure 1 Shown, in the present embodiment, a kind of method for preventing the surface corrosion of soft package lithium-ion battery, this method comprises the following steps:

[0020] (1) In the assembly process of flexible packaging lithium-ion batteries, after the positive sealing process of the battery cells, a protective film is added to the surface of the battery cells. The protective film is a PE protective film with a temperature resistance higher than 80 ° C. The protective film is used to stick to the battery. The core part and does not stick to the air bag part;

[0021] (2) The lithium-ion battery with the protective film attached is still operating in accordance with the normal operating procedures;

[0022] (3) Remove the attached protective film before the final inspection and storage of lithium-ion batteries.

[0023] The operation procedure in said step (2) includes the following steps:

[0024] a. Inject liquid after baking; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com