Method for processing surface of highlight edge copper cladding aluminum buckle cover and complete buckle

A technology of surface treatment and treatment method, applied in the field of surface treatment of high-gloss copper-clad aluminum buckle cover and whole buckle, can solve the problems of inability to meet high quality requirements, corrosion and other problems, achieve a beautiful overall pattern of the buckle cover, and improve the degree of oxidation resistance , The effect of not easy to change color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

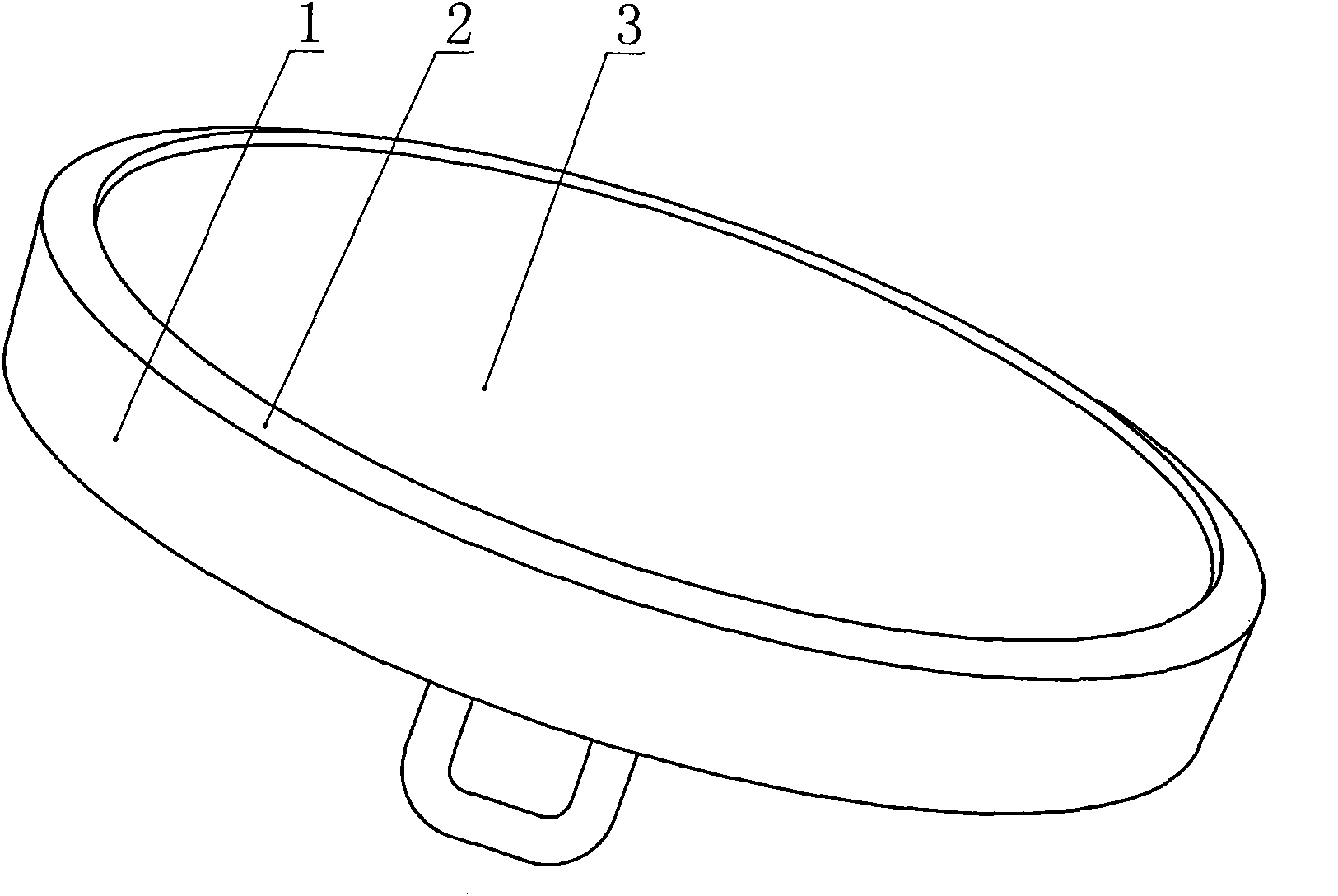

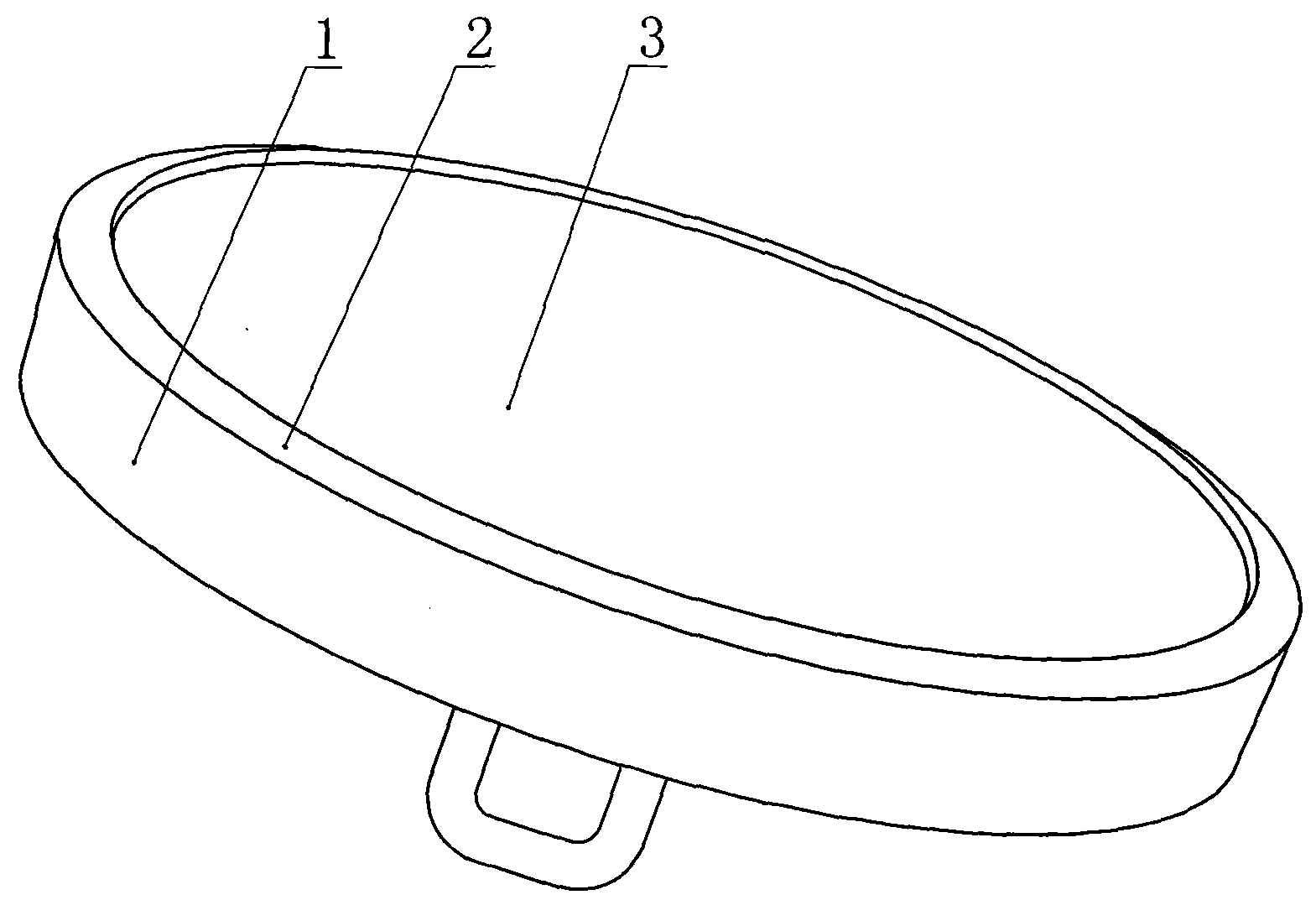

Image

Examples

Embodiment 1

[0049] A surface treatment method for a high-gloss edge copper-clad aluminum buckle cover, the steps of the treatment method are:

[0050] (1) Degreasing the buckle cap: place the buckle cap after embossing and blanking in a degreasing liquid at a temperature of 80°C, and keep it for 2 minutes. The components and weight / number ratio of the degreasing liquid are: 98% industrial sodium hydroxide 125 parts of aqueous solution; 55 parts of 85% sodium tripolyphosphate aqueous solution; 9 parts of OP-10 emulsifier; 811 parts of water;

[0051] (2) neutralization of the buckle cap: put the buckle cap after degreasing treatment into 19% nitric acid solution for 12 seconds;

[0052] (3) Cap polishing: put the neutralized cap into a polishing solution at 40° C. for 60 seconds. The components and parts by weight of the polishing solution are: 450 parts of 35% hydrogen peroxide solution; 175 parts of 96% ethanol solution; 3 parts of zinc acetate; 45 parts of 96% nitric acid solution; 327...

Embodiment 2

[0070] A surface treatment method for a copper-clad aluminum buckle cover with high-gloss edges, characterized in that: the steps of the treatment method are:

[0071] (1) Degreasing the buckle cap: place the buckle cap after embossing and blanking in a degreasing liquid at a temperature of 80°C, and keep it for 2 minutes. The components and weight / number ratio of the degreasing liquid are: 98% industrial sodium hydroxide 100 parts of aqueous solution; 50 parts of 85% sodium tripolyphosphate aqueous solution; 8 parts of OP-10 emulsifier; 780 parts of water;

[0072] (2) neutralization of the buckle cap: put the buckle cap after the degreasing treatment into a 19% nitric acid solution for 10 seconds;

[0073] (3) Cap polishing: put the neutralized cap into a polishing solution at 35° C. for 40 seconds. The components and parts by weight of the polishing solution are: 400 parts of 35% hydrogen peroxide solution; 150 parts of 96% ethanol solution; 2 parts of zinc acetate; 40 par...

Embodiment 3

[0084] A surface treatment method for a copper-clad aluminum buckle cover with high-gloss edges, characterized in that: the steps of the treatment method are:

[0085] (1) Degreasing the buckle cover: place the buckle cover after embossing and blanking in a degreasing liquid at a temperature of 100°C, and keep it for 2 minutes. The components and weight / number ratio of the degreasing liquid are: 98% industrial sodium hydroxide 150 parts of aqueous solution; 60 parts of 85% sodium tripolyphosphate aqueous solution; 10 parts of OP-10 emulsifier; 842 parts of water;

[0086] (2) neutralization of the buckle cap: putting the buckle cap after the degreasing treatment into a 19% nitric acid solution for 15 seconds;

[0087] (3) Cap polishing: put the neutralized cap into a 45°C polishing solution for 80 seconds, the components and weight-to-number ratios of the polishing solution: 500 parts of 35% hydrogen peroxide solution; 200 parts of 96% ethanol solution; 5 parts of zinc acetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com