Camera module test method, device, test drawing board and system

A technology of camera module and test method, which is applied in image communication, television, electrical components, etc., can solve the problems of low definition of calibration reference image and affect the accuracy of OIS calibration results, so as to improve accuracy, improve black-and-white contrast, The effect of ensuring focus accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

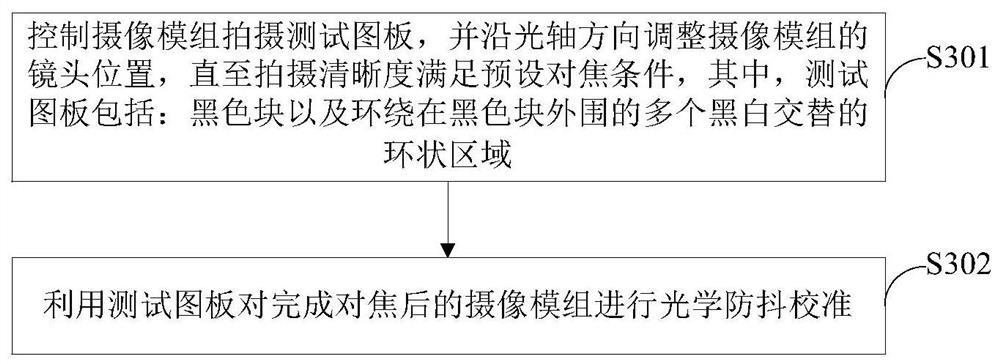

[0037] In order to better understand the technical solutions provided by the embodiments of this specification, the technical solutions of the embodiments of this specification will be described in detail below through the drawings and specific examples. The detailed description of the technical solutions of the embodiments is not a limitation to the technical solutions of this specification. In the case of no conflict, the embodiments of this specification and the technical features in the embodiments can be combined with each other.

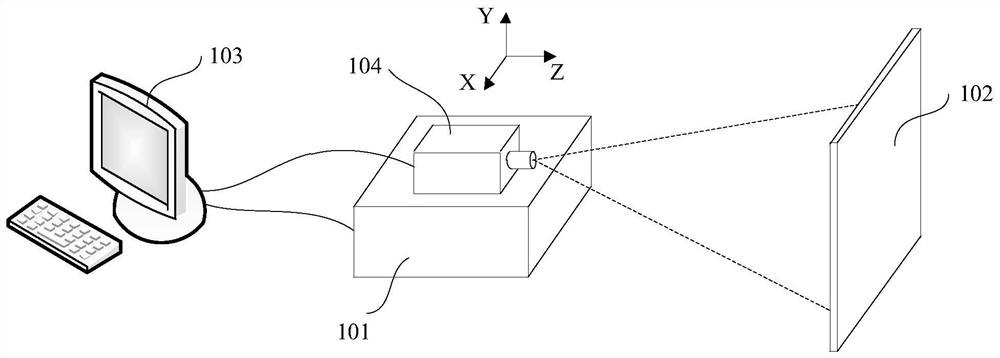

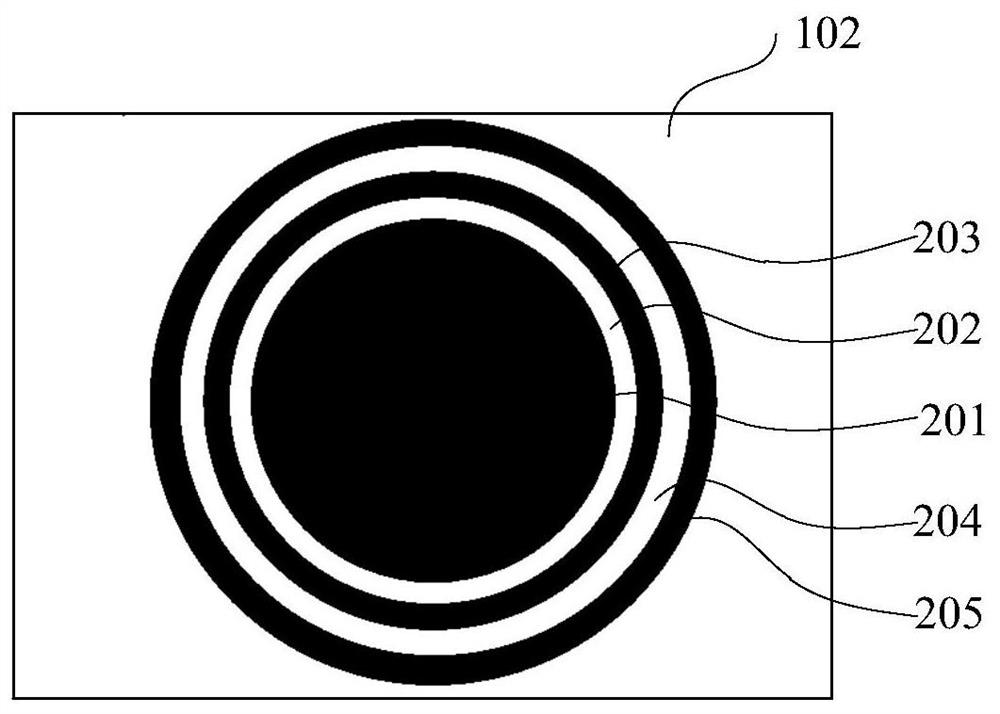

[0038] figure 1 An exemplary camera module testing system provided by the embodiment of this specification is shown, and the camera module testing system includes: a vibrating table 101 , a test pattern board 102 and a host computer 103 . Wherein, the host computer 103 is respectively connected with the vibrating table 101 and the camera module 104 to be tested, and is used to execute the camera module testing method provided in the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com