Mask structure of LCD display screen and manufacturing process thereof

A technology of LED display screen and manufacturing process, which is applied in the direction of instruments, identification devices, etc., to achieve the effect of reducing spacing, improving product reliability, and good picture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

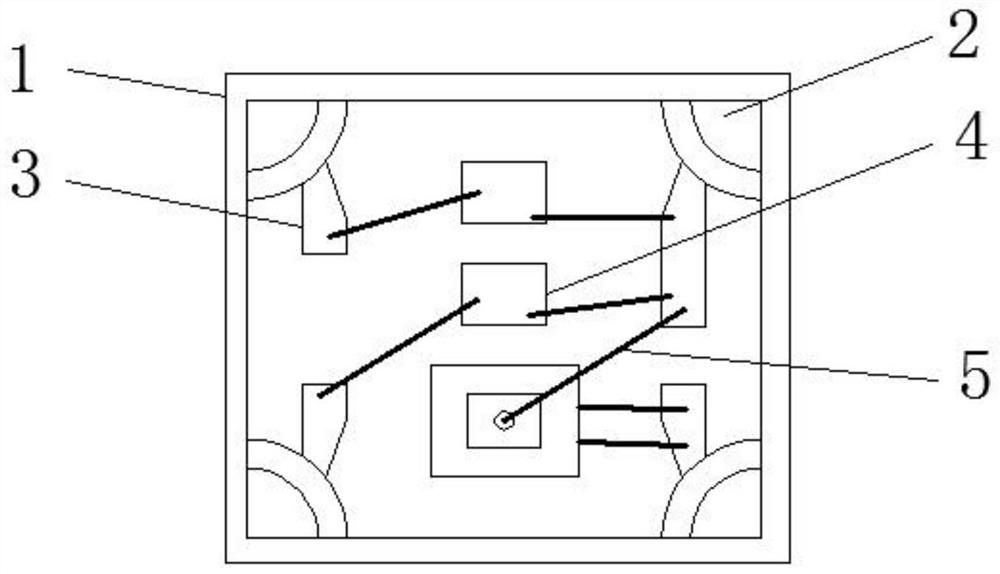

[0025] see figure 1 , in an embodiment of the present invention, a mask structure of an LCD display screen and its manufacturing process, the LED display screen is provided with a circuit cavity, the circuit cavity is provided with a circuit substrate 1, and the circuit substrate 1 is made of resin, Quartz and ceramics are made by mixing one or more of them. The upper and lower sides of the circuit substrate 1 are respectively provided with positive circuit lines and reverse circuit lines. The four corners of the circuit substrate 1 are all provided with wire holes 2. The wires of the positive circuit extend through the wire hole 2 and are connected to the reverse circuit, and the positive circuit is provided with a plurality of optical fixed sections 3 above, and ordinary light chips with different contrasts are respectively arranged in the fixed optical sections 3, The optical fixed sections 3 are respectively located on the sides of the wire holes 2, and the optical fixed s...

Embodiment 2

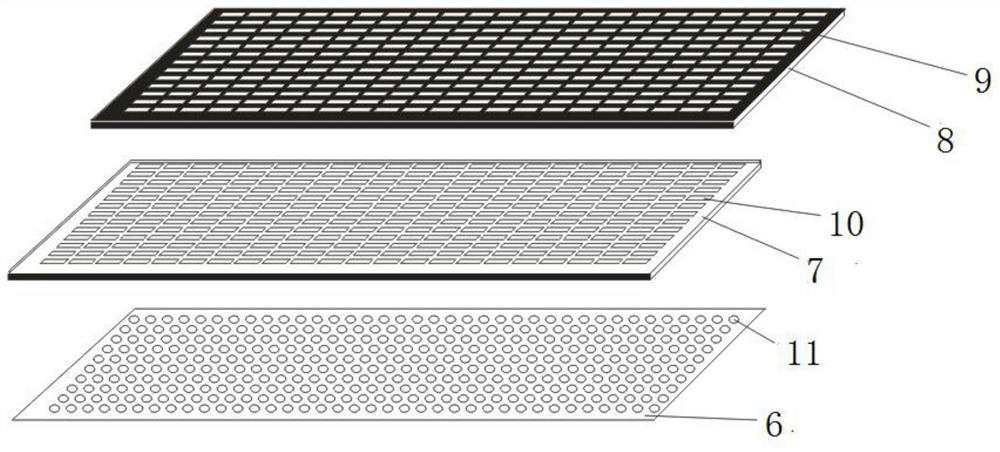

[0028] The present invention also provides a LED display screen string light surface treatment process. The outer casing of the LED display screen includes a press-fit plate and a mask. The mask is provided with several lines and is supported and fixed between adjacent press-fit plates. The surface treatment process includes the following steps:

[0029] The outer casing of the LED display screen includes a pressing plate 7 and a mask 8, the mask 8 is attached to the upper plane of the pressing plate 7, and the pressing plate 7 is provided with several light-transmitting holes 10, and the mask 8 is Several astigmatism holes 9 are provided, and the astigmatism holes 9 and the light transmission holes 10 are located on the same axis line, and the surface treatment process includes the following steps:

[0030] S1: Precision stamping: The press-fit plate 7 with high hardness is used, and the press-fit plate 7 and the mask 8 are pressed together by precision stamping; it is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com