COB display screen mask and operation method thereof

A display screen and mask technology, applied in the field of COB display screen masks, can solve problems such as difficulty in adjusting contrast, large gaps in the inner cavity of the mask, and difficult light treatment, so as to reduce light loss, improve black and white contrast and clarity, and avoid polarized light Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

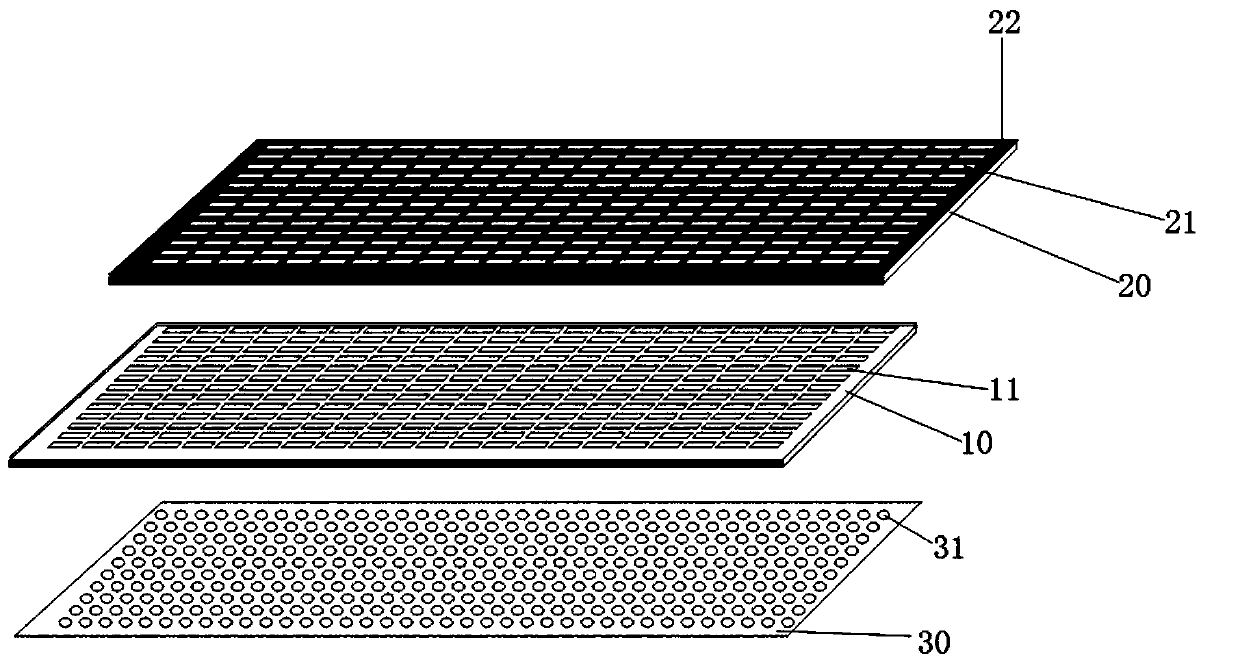

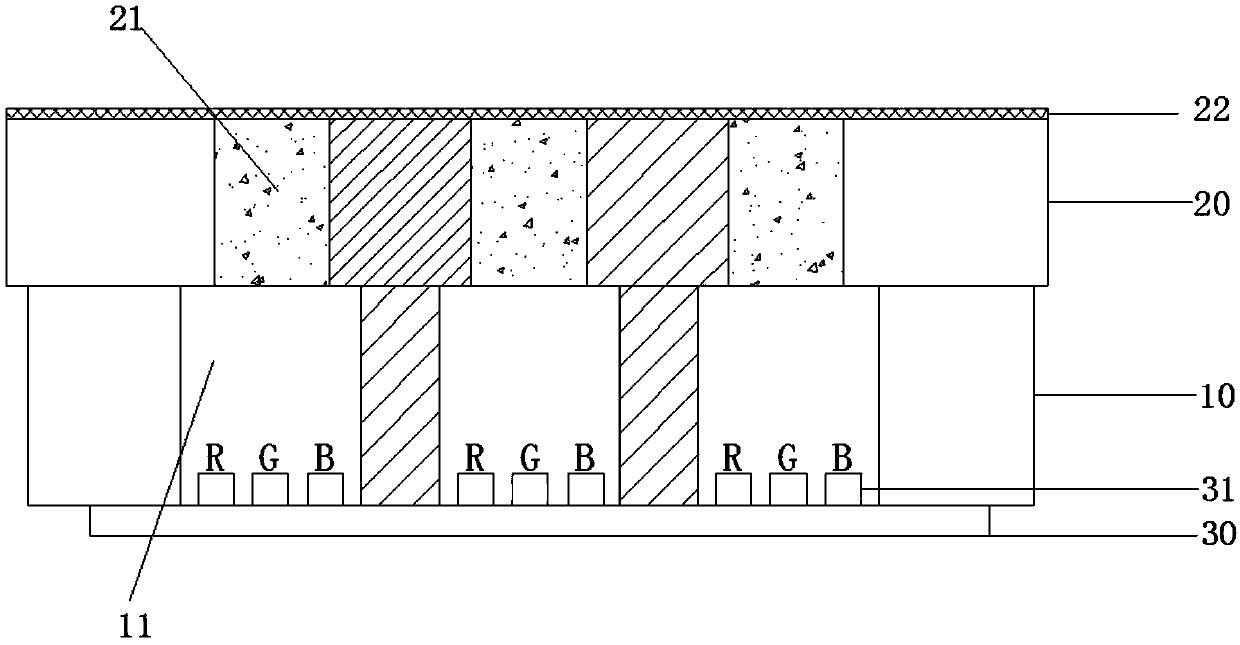

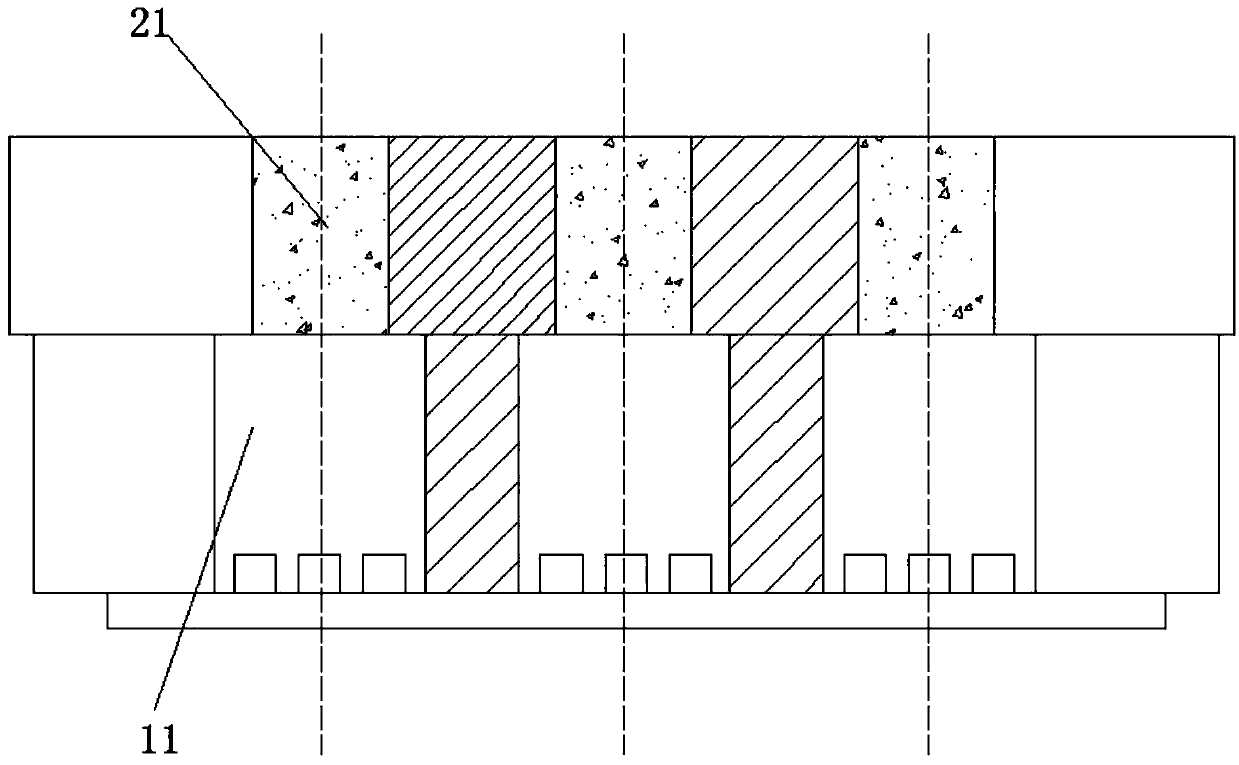

[0030] see figure 1 with figure 2 , a COB display screen mask, including a first mask 10 and a second mask 20, the first mask 10 is covered on the second mask 20, and several roads are respectively arranged on the first mask 10 and the second mask 20 The first mask hole 11 and several second mask holes 21, the first mask 10 and the second mask 20 are all made of aluminum alloy material by precision stamping, so that the whole mask is accurate and uniform in size, smooth in surface, free from spots and No scars, no scratches, no surface cracks; at the same time, the alloy material has a good light-shielding effect and good heat dissipation.

[0031] The first mask hole 11 and the second mask hole 21 match each other and are located on the same axis, the first mask hole 11 inner diameter is greater than the second mask hole 21 inner diameter, the first mask 10 and the second mask 20 All surfaces are mirror-finished.

[0032] During operation, the first mask 10 and the second...

Embodiment 2

[0038] see figure 1 with figure 2 , as a further optimization of Embodiment 1, the difference is that the upper surface of the second mask 20 has a matte surface 7, the matte surface 7 is formed by mirror-removing treatment, and the matte surface 7 is then sprayed or painted. Oxidation or plating treatment forms a black matte. Due to the low reflectivity of black, it effectively reduces the situation that external light touches the upper surface of the second mask 20 to generate reflection; meanwhile, the matte surface 7 further forms diffuse reflection and irregular reflection, which reduces the interference to the light emission of the display screen body , thus further improving the black and white contrast and clarity of the display.

Embodiment 3

[0040] On the basis of the above-mentioned embodiments, the present invention also provides a working method for a COB display screen mask, the working method comprising the following steps:

[0041] 1) Stamping forming: high-density aluminum alloy material is selected and pressed tightly by equipment to form the first mask 10 and the second mask 20; the inner diameters of the first mask hole 11 and the second mask hole 21 are based on the contrast of the corresponding model display screen And design, simultaneously described first mask hole 11 internal diameters are greater than the second mask hole 21 internal diameters, are designed as the structural feature that up is small and bottom is big.

[0042] 2) mirror surface treatment: carry out mirror surface treatment to the surface of the first mask 10 and the second mask 20, increase the surface brightness to 30%, thereby improving the reflection effect and light guiding effect of the mask holes;

[0043] 3) Pressing operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com