Method for allowing hot rolled strip steel to pass through fault rolling mill without being rolled

A hot-rolled strip, failure technology, applied in the safety equipment of rolls, metal rolling, metal rolling, etc., can solve the problems that affect the continuous use of the rolls, the wear of the rolls is very severe, affect the surface quality, etc., and reduce the downtime of the whole line. time, improve the operation rate and output, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

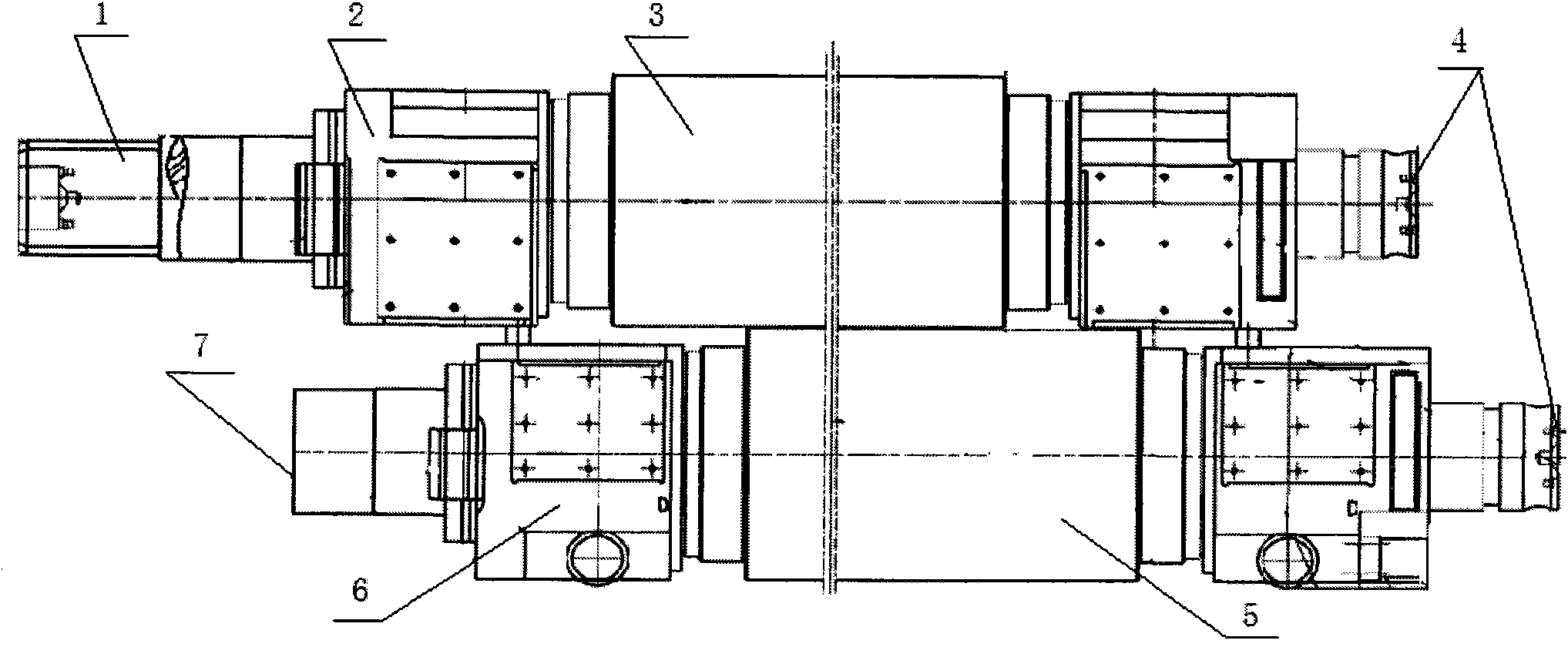

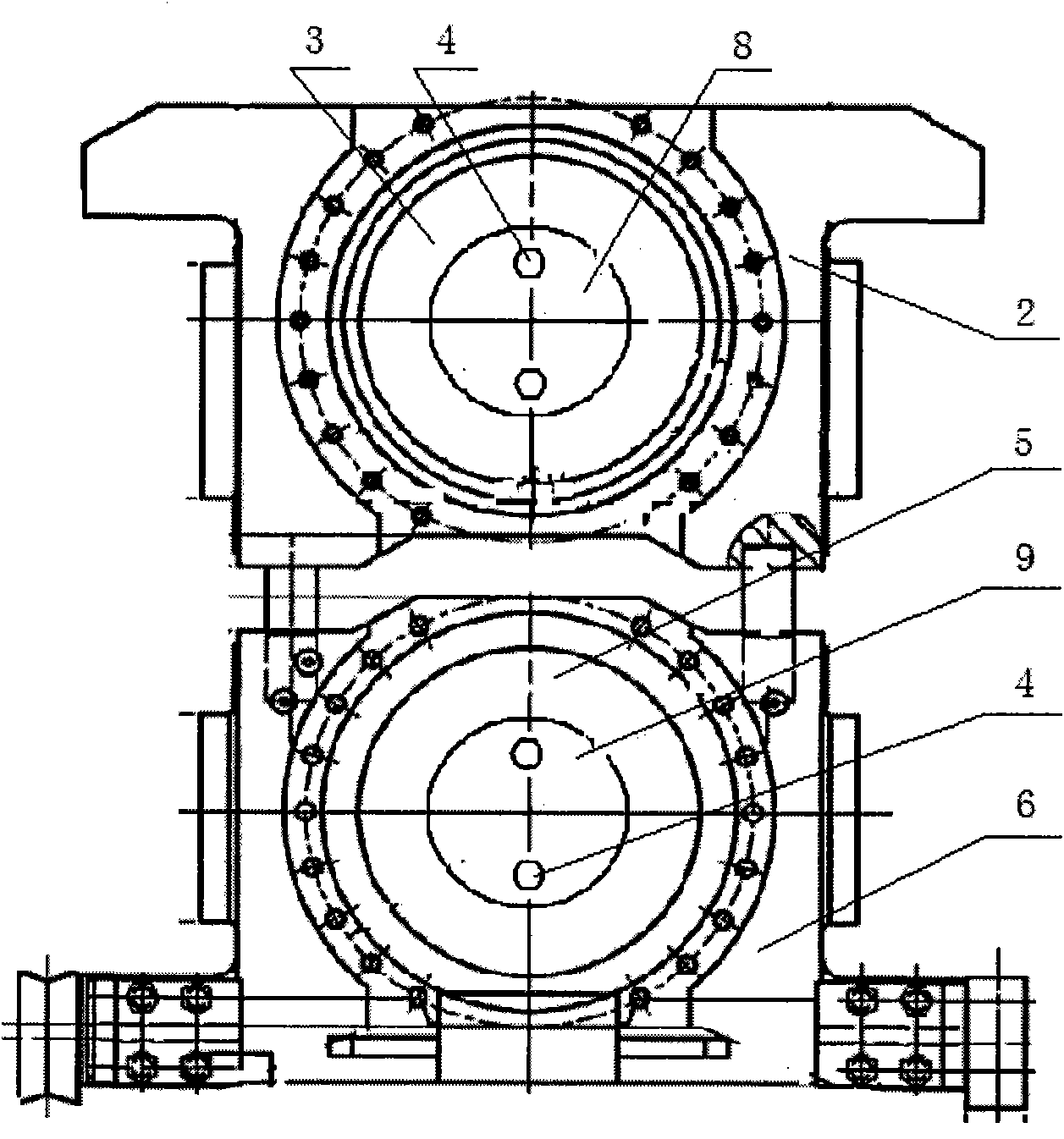

[0022] Hereinafter, the present invention will be further described with reference to the accompanying drawings.

[0023] The method of the hot-rolled strip fault rolling mill emptying of the present invention, its concrete steps are as follows:

[0024] 1. Reconstruction of waste rollers

[0025] In order to save money and reduce production costs, the present invention makes full use of the old work rolls that have been scrapped on the finishing line to realize the reuse of the scrap rolls.

[0026] Remove the scraped upper work roll 3 and lower work roll 5 from the flat head part 1 of the transmission side to form the shape of the transmission side 7 without the flat head, so as to ensure that the upper work roll 3 and the lower work roll 5 after being installed are not in contact with the transmission shaft. . In addition, two torsion holes 4 are drilled in the upper work roll head 8 and the lower work roll head 9 on the work side, respectively.

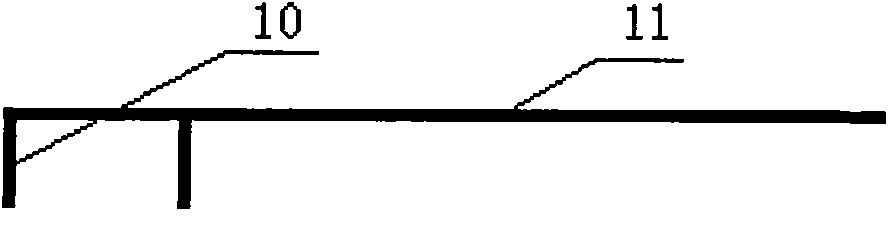

[0027] To make a torsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com