Method for preparing cement clinker from high-proportion carbide slag through decomposition outside kiln of five-stage preheater

A technology for decomposing cement clinker outside the kiln, which is applied in cement production and other directions, can solve the problems of poor thermal energy utilization efficiency, shorten service life, increase system heat consumption, etc., to improve equipment operation rate, prolong service life, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

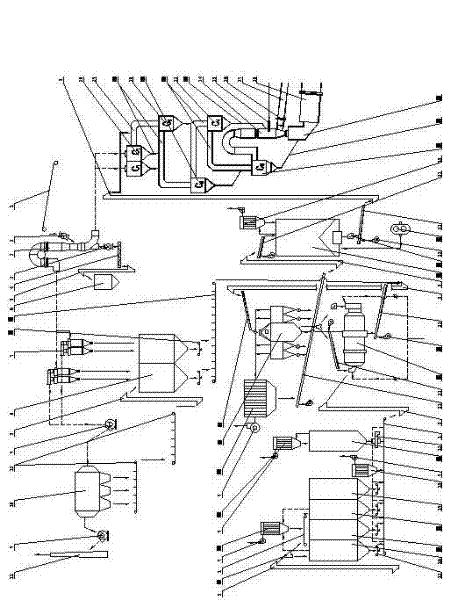

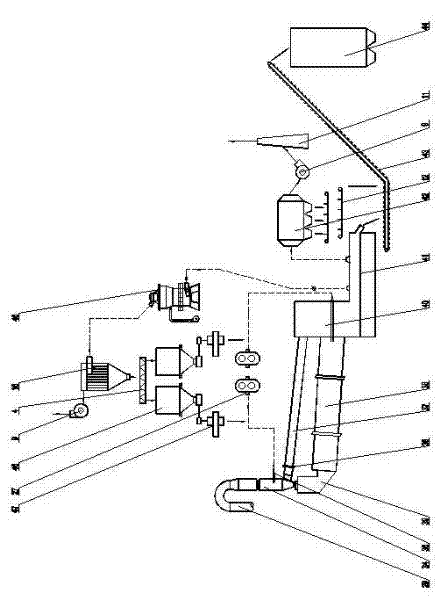

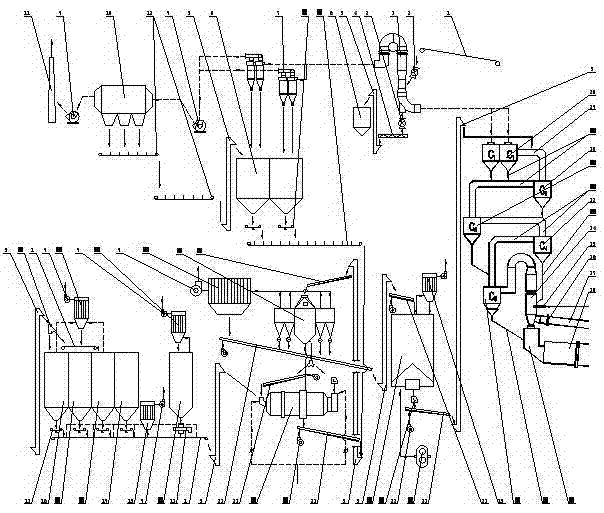

Image

Examples

Embodiment

[0027] Embodiment: The method for producing cement clinker by decomposing the five-stage preheater outside the kiln with a high proportion of calcium carbide slag ingredients is completed in three steps: carbide slag drying, raw meal grinding, and clinker firing. The equipment involved is Commercially available conventional products, the specific structure is not described here.

[0028] 1. The drying step of carbide slag includes two processes of simultaneous drying and impurity removal:

[0029] ①Drying: Wet calcium carbide slag with a moisture content of ≤10% is transported by the belt conveyor 1, and sent into the dryer 3 through the rotary air-lock feeder 2, and the dryer 3 and the first-stage cyclone of the kiln tail preheater of the rotary kiln 38 The pipe 29 of the wind outlet of the barrel 28 is connected. When the waste heat flue gas from the first-stage cyclone barrel 28 passes through the drier 3, it exchanges heat with the carbide slag in a suspended state. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com