Novel carbon dioxide trapping device performing liquefaction and then sublimation

A carbon dioxide and capture device technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve problems such as difficult equipment management, high requirements for raw material gas, and complicated membrane production process, so as to avoid serious corrosion and save energy. The effect of liquefaction energy consumption and capture rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

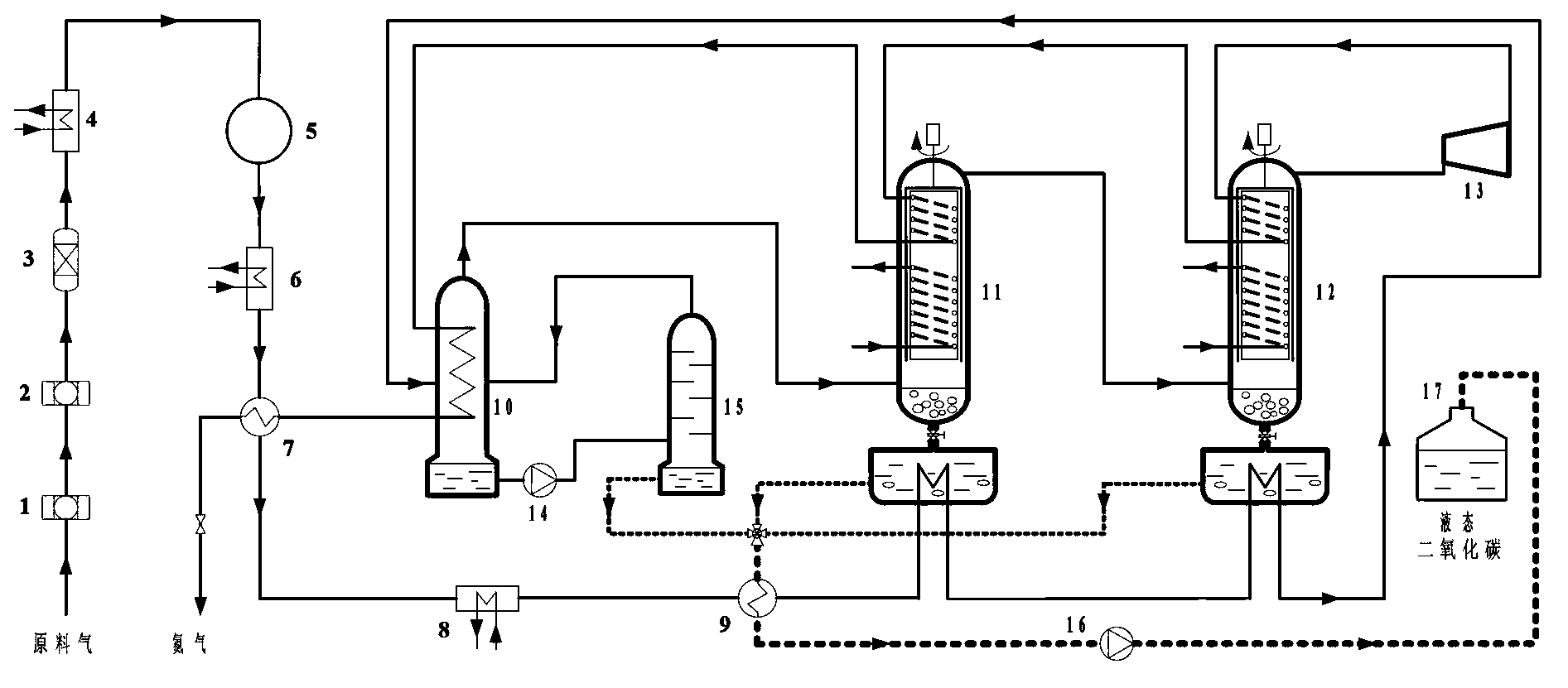

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, a new type of carbon dioxide capture device for liquefaction and recondensation, which includes a filter 1, an adsorber 2, a dryer 3, a first heat exchanger 4, a compressor 5 and a second heat exchanger 6 connected in sequence . The raw gas passes through the filter 1, the adsorber 2 and the dryer 3, so that the raw gas is dried and purified before the carbon dioxide gas is captured; some solid impurities are removed through the filter 1, and then the acid gas is absorbed through the adsorber 2, and finally Moisture is removed by dryer 3. Compared with the alcohol amine absorption method widely used at present, this system does not use solvents for chemical reactions such as alcohol amine, which avoids the generation of toxic substances and serious corrosion of equipment.

[0021] The outlet of the second heat exchanger 6 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com