Jet atomization type mining rotational-flow inertial dust remover and application process thereof

A dust collector and cyclone technology, applied in the field of jet atomization type mine cyclone inertial dust collector, can solve the problems of not fully utilizing the unique equipment of coal mines, low dust removal efficiency, unreasonable process settings, etc. Maintain, ensure reasonable and complete results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

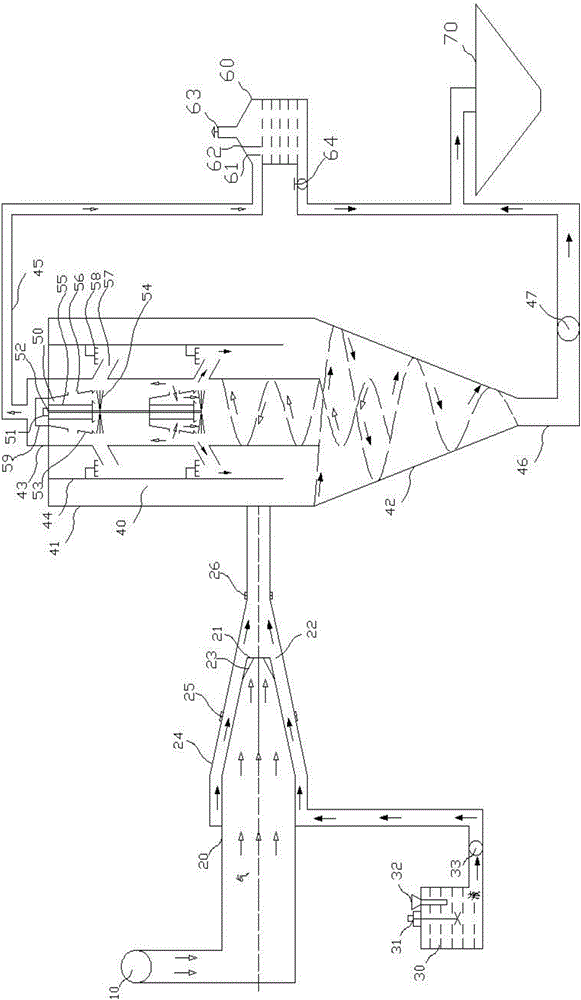

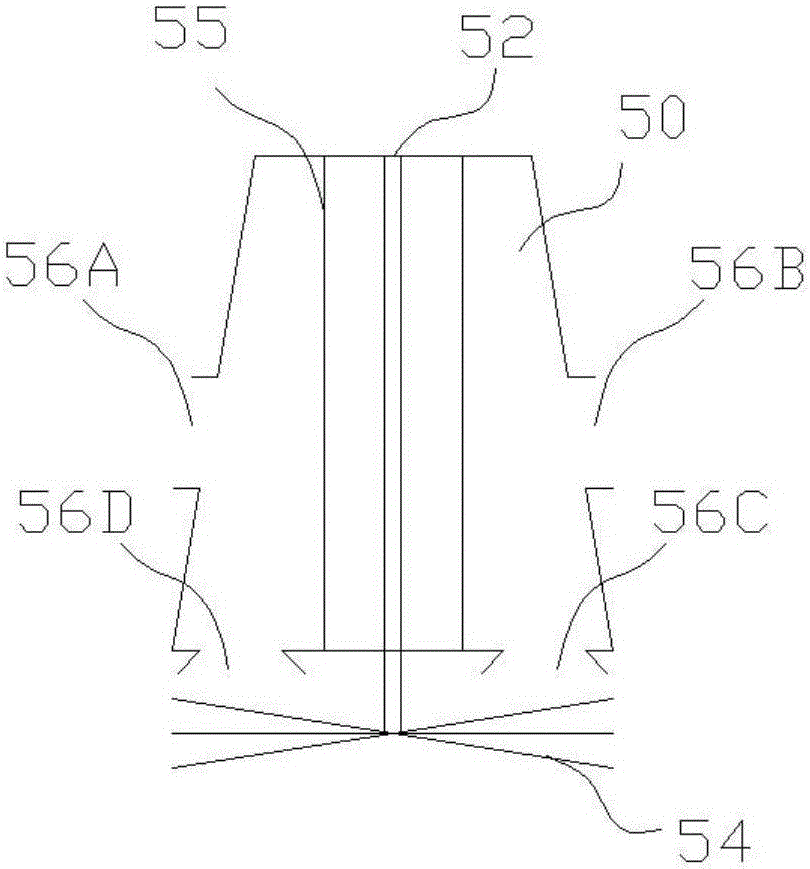

[0030] For ease of understanding, combined here Figure 1-4 , the specific embodiments of the present invention are further described as follows:

[0031] The specific components of the present invention are divided into several modules, including: feeding system, annular sleeve jet nozzle 20, cyclone dust collector 40, rotary impeller inertial dust removal device 50, gas-water separator 60 and concentrator 70. Describe them one by one below:

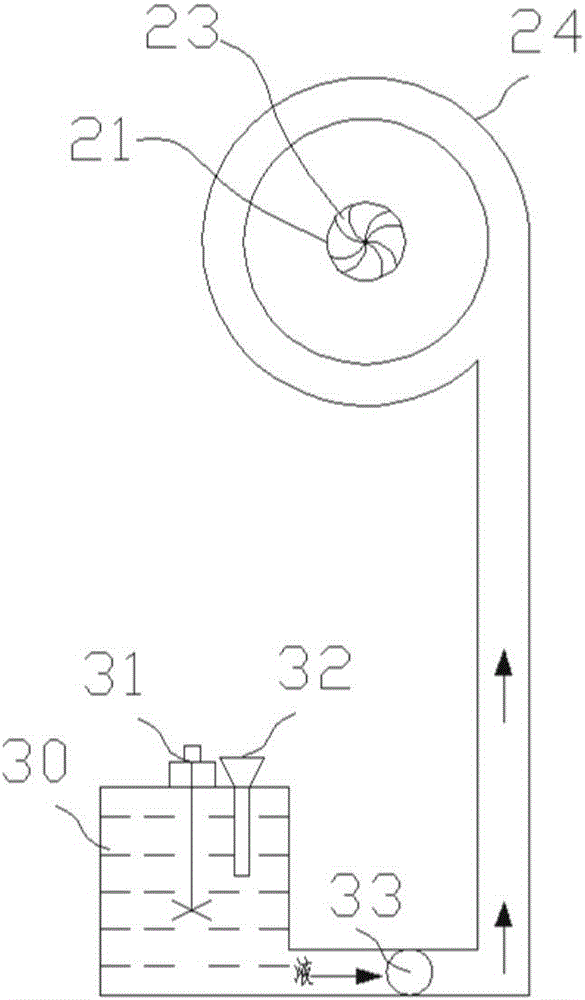

[0032] 1. Feeding system

[0033] The feeding system consists of two parts, the first part: the dust-laden gas conveying fan 10 conveys the dust-laden gas into the inner nozzle 21 of the annular sleeve jet nozzle 20; The funnel 32 is added to the water, under the agitation of the impeller agitator 31, it is preliminarily dispersed and mixed, and fed into the outer annular nozzle 22 of the annular sleeve jet nozzle 20 by the pump 33 in a tangential feeding mode.

[0034] 2. Annular sleeve jet nozzle

[0035] The inner nozzle 21 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com