Fluidized bed boiler combustion use garbage derivative fuel device and use method thereof

A waste-derived fuel, fluidized-bed boiler technology, which is applied in the use of liquid cleaning methods, combustion methods, chemical instruments and methods, etc. Boiler safe operation and other issues, to prevent damage to boiler equipment, avoid subsequent resource utilization, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

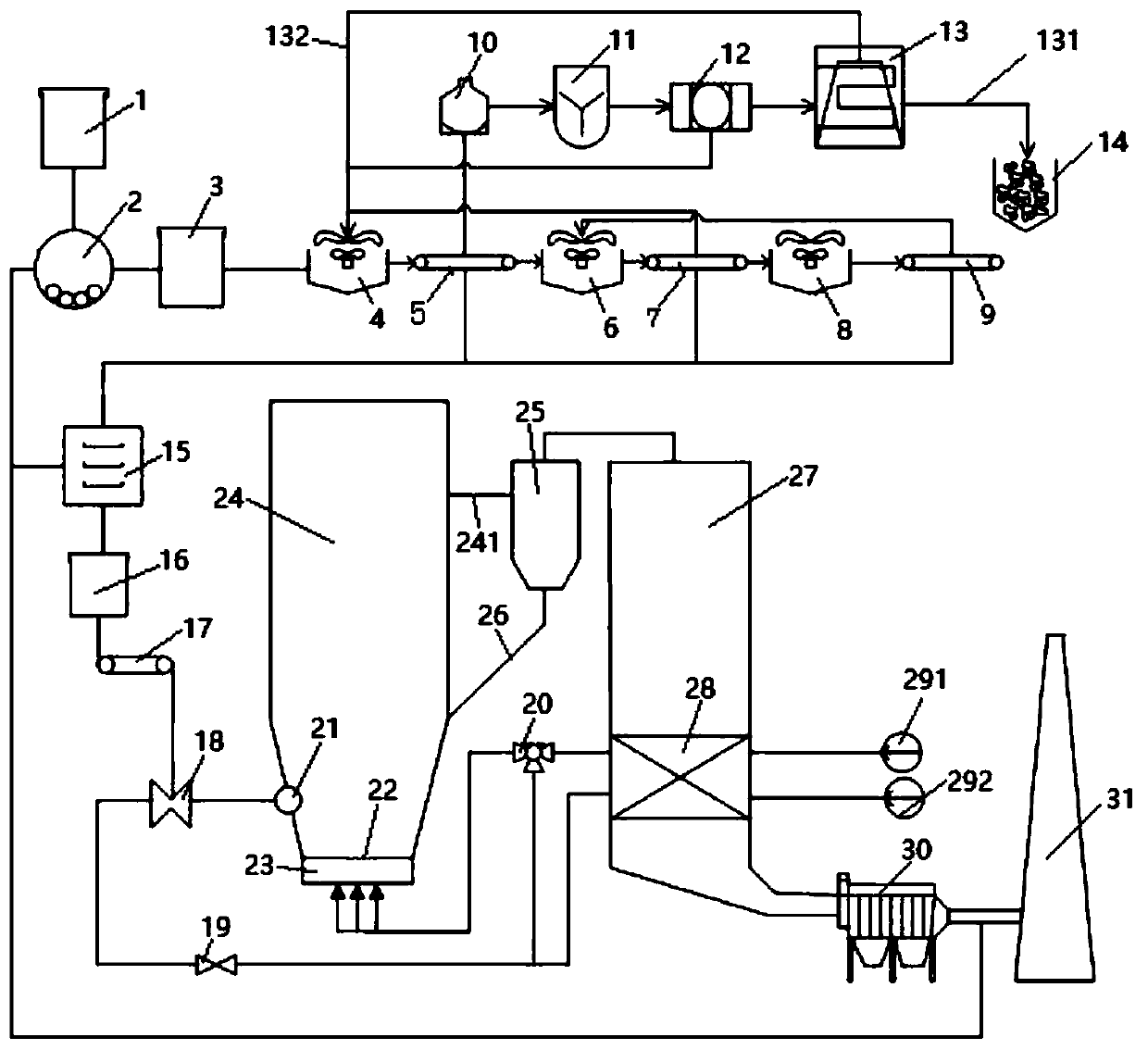

[0027] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0028]The invention provides a device for burning garbage-derived fuel in a fluidized bed boiler that inhibits chlorine salt corrosion, including a garbage drying and crushing device, a garbage washing device and a boiler coordination device. The water washing centrifuge device includes a water washing box and a centrifuge, the outlet of the water washing box at the same level is connected to the inlet of the centrifuge, and the first solid outlet of the centrifuge at this level is connected to the next level through the first control valve. The inlet of the washing tank, the liquid outlet of the centrifuge in this stage is connected to the inlet in the washing tank of any previous stage; preferably, the liquid outlet of the centrifuge in this stage is connected to the inlet of the washing tank in the previous stage, and the garbage is sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com