Quick repair mortar for high-speed railway concrete track slab and preparation method thereof

A high-speed railway and repair mortar technology, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low 28d strength, harsh construction environment requirements, poor repair interface stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

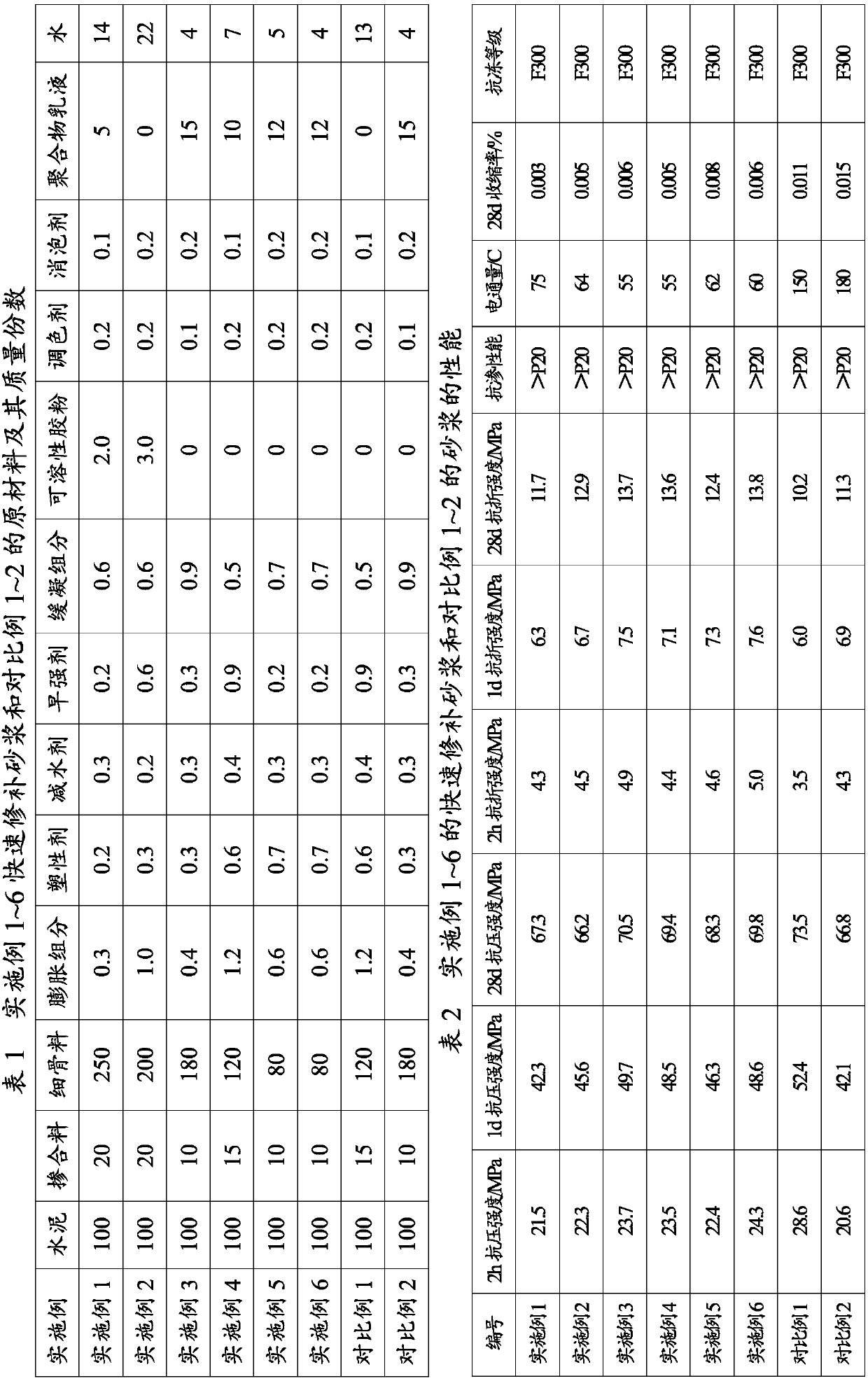

[0048] Example 1 A quick repair mortar for high-speed railway concrete track slab

[0049] Quick repair mortar raw material and mass parts thereof in the present embodiment are as shown in table 1; Wherein,

[0050] The cement is grade 52.5 rapid-hardening sulfoaluminate cement; the mineral admixture is grade I fly ash; the fine aggregate is machine-made sand with continuous particle gradation of 40 mesh to 120 mesh; Plastic expansion agent and UEA expansion agent; plastic agent is hydroxypropyl methylcellulose ether; water reducer is polycarboxylate water reducer; early strength agent is lithium carbonate; retarding component is tartaric acid with a mass ratio of 1:1 and boric acid; the soluble rubber powder is acrylate and styrene copolymer powder (mass ratio 1:1); the defoamer is a silicone defoamer; the toner is carbon black; the polymer emulsion is an improved solid content of 48%. Non-toxic acrylic emulsion.

[0051] The quick repair mortar is prepared by the followin...

Embodiment 2

[0053] Example 2 A quick repair mortar for high-speed railway concrete track slab

[0054] The rapid repair mortar raw materials and mass parts thereof in the present embodiment are as shown in Table 1, wherein:

[0055] The cement is 52.5 grade rapid hardening sulfoaluminate cement and superfine Portland cement with a mass ratio of 4:1; the mineral admixture is silica fume and Class I fly ash with a mass ratio of 2:3; the fine aggregate is water-containing 40 mesh to 120 mesh river sand with a ratio of 0.1%; the expansion component is 200 mesh scale aluminum powder with a mass ratio of 1:2:12, plastic expansion agent and UEA expansion component; the plastic agent is hydroxypropyl methylcellulose plain ether; the water reducer is polycarboxylate water reducer; the early strength agent is lithium carbonate and calcium formate with a mass ratio of 1:10; the retarding component is tartaric acid and citric acid with a mass ratio of 1:1; the soluble rubber powder is Acrylate and...

Embodiment 3

[0058] Example 3 A quick repair mortar for high-speed railway concrete track slab

[0059] The rapid repair mortar raw materials and mass parts thereof in the present embodiment are as shown in Table 1, wherein:

[0060] The cement is 42.5 grade rapid-hardening sulfoaluminate cement; the mineral admixture is silica fume; the fine aggregate is 40-120 mesh river sand with a moisture content of 0.1%; the expansion component is a plastic expansion agent with a mass ratio of 1:12 and UEA expansion component; the plasticizer is modified starch and hydroxypropyl methylcellulose ether with a mass ratio of 1:1; the water reducer is polycarboxylate water reducer; the early strength agent is lithium hydroxide; Borax and citric acid are divided into 2:1; the defoamer is a silicone defoamer; the toner is carbon black; the polymer emulsion is a modified acrylic emulsion with a solid content of 48%.

[0061] The quick repair mortar is prepared by the following method:

[0062] After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com