Low-loss optical fiber and manufacturing method thereof

A manufacturing method and low-loss technology, applied in cladding optical fiber, manufacturing tools, glass manufacturing equipment, etc., to achieve the effects of reducing interface stress, good control, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

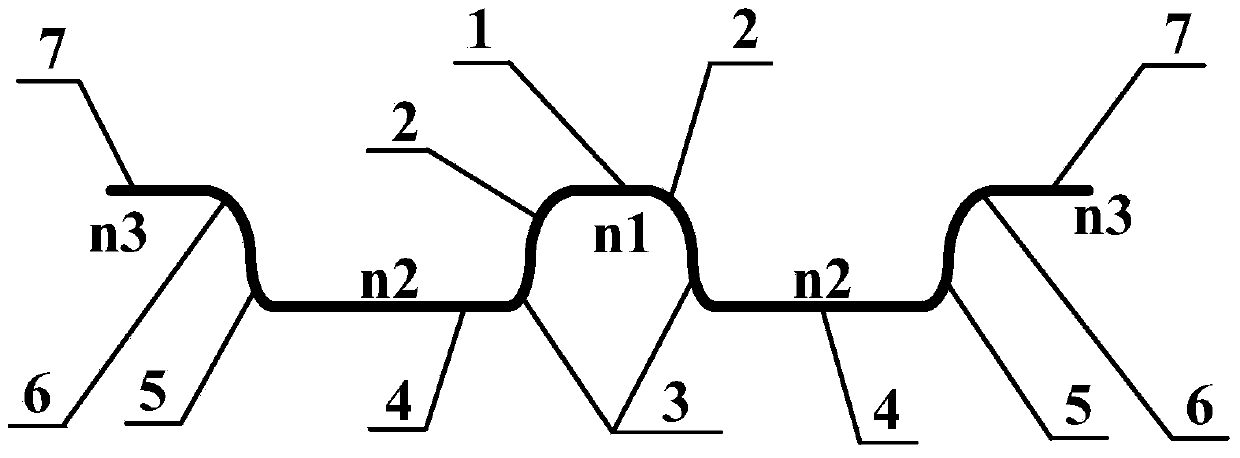

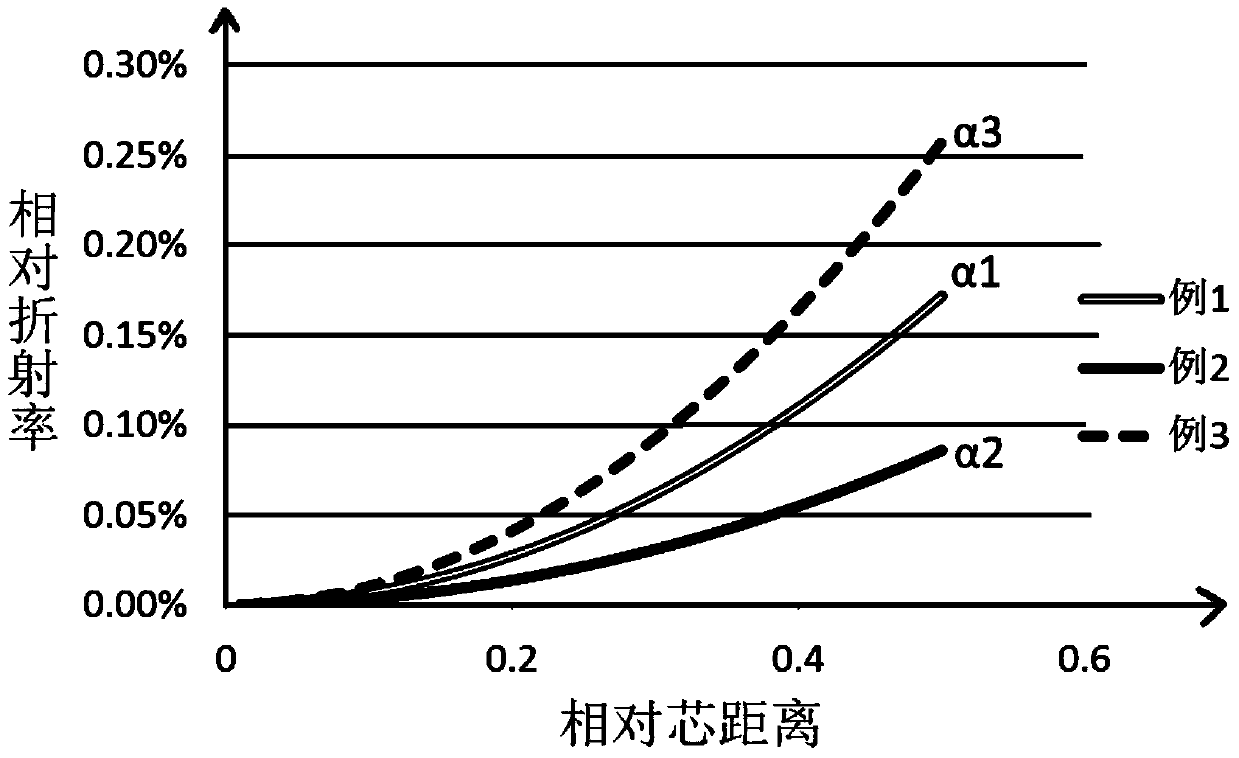

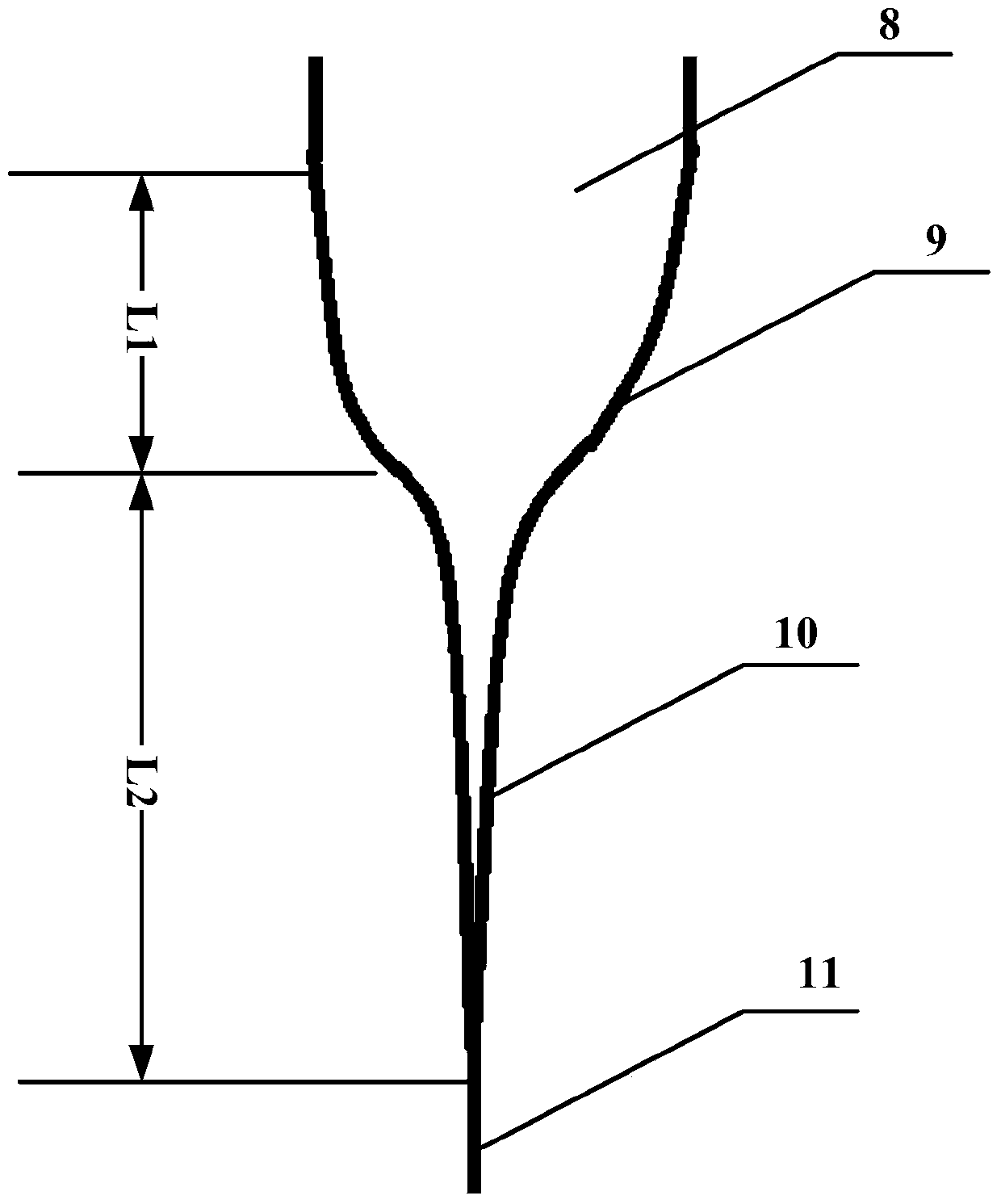

[0041] On the inner wall of a high-purity quartz reaction tube, according to the order from outside to inside, first deposit the cladding interface transition layer 6, then deposit the cladding transition layer 5, then deposit the deep fluorine-doped cladding 4, and then deposit the core cladding interface The transition layer 3 and the core-covered transition layer 2, and finally the core layer 1 is deposited. The specific process is as follows: firstly, the initial value of the base point temperature is set at 900°C, and the cladding interface transition layer 6 is first deposited on the high-purity quartz reaction tube, and its waveguide structure The curve follows the parabolic formula Y=α 1 x 2 , where: Y is the relative refractive index difference, X is the relative distance from the starting point of the refractive index change, α 1 is the stress coefficient, the stress coefficient α in this embodiment 1 The absolute value of remains unchanged, the value is 0.01, and ...

Embodiment 2

[0045] Example 2: The core layer is slightly doped with fluorine

[0046] On the inner wall of a high-purity quartz reaction tube, according to the order from outside to inside, first deposit the cladding interface transition layer 6, then deposit the cladding transition layer 5, then deposit the deep fluorine-doped cladding 4, and then deposit the core cladding interface The transition layer 3 and the core-wrapped transition layer 2, and finally the core layer 1 is deposited. The specific process is as follows: first, the initial value of the base point temperature is 930°C, and the cladding interface transition layer 6 is first deposited on the high-purity quartz reaction tube. The waveguide structure curve Follow the parabolic formula Y=α 2 x 2 +b, where: Y is the relative refractive index difference, X is the relative distance from the starting point of the refractive index change, α 2 is the stress coefficient, b is the change constant of the interface refractive index,...

Embodiment 3

[0050] Example 3: The core layer is slightly doped with fluorine

[0051] On the inner wall of a high-purity quartz reaction tube, according to the order from outside to inside, first deposit the cladding interface transition layer 6, then deposit the cladding transition layer 5, then deposit the deep fluorine-doped cladding 4, and then deposit the core cladding interface The transition layer 3 and the core-wrapped transition layer 2, and finally the core layer 1 is deposited. The specific process is as follows: first, the initial value of the base point temperature is 950°C, and the cladding interface transition layer 6 is first deposited on the high-purity quartz reaction tube. The waveguide structure curve Follow the parabolic formula Y=α 3 x 2 , where: Y is the relative refractive index difference, X is the relative distance from the starting point of the refractive index change, α 3 is the stress coefficient, the stress coefficient α in this embodiment 3 The absolute v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com