Flexible display assembly, fabrication method thereof and display panel

A flexible display and component technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as easy cracking of display panels, achieve the effect of improving cracking and bending reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

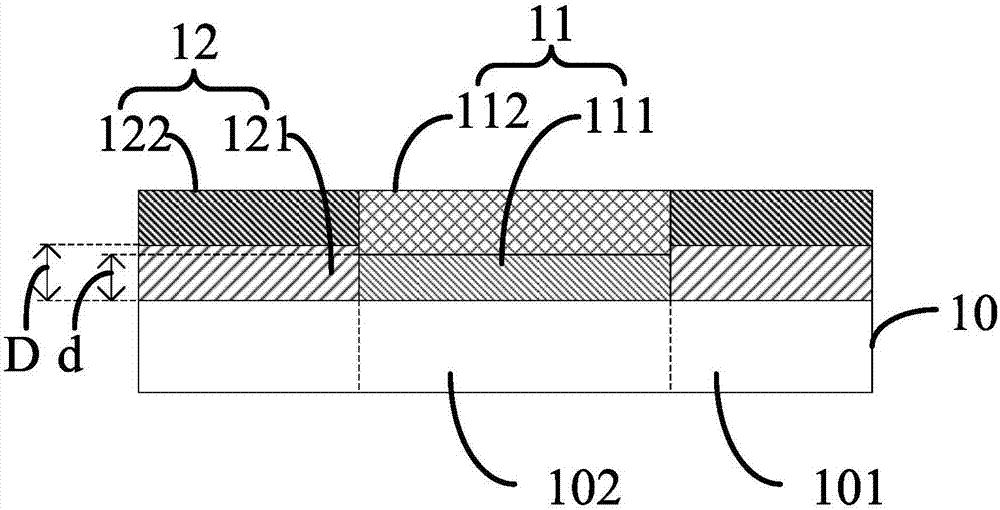

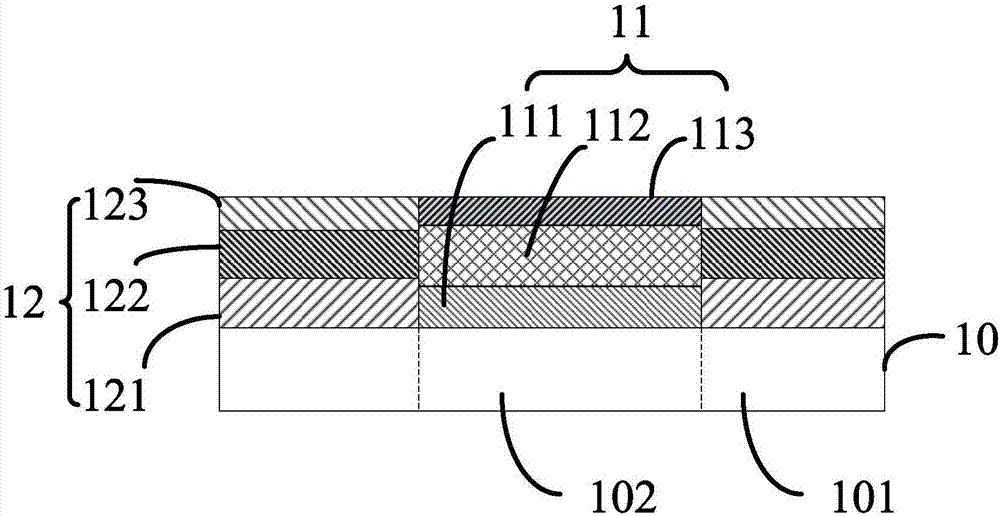

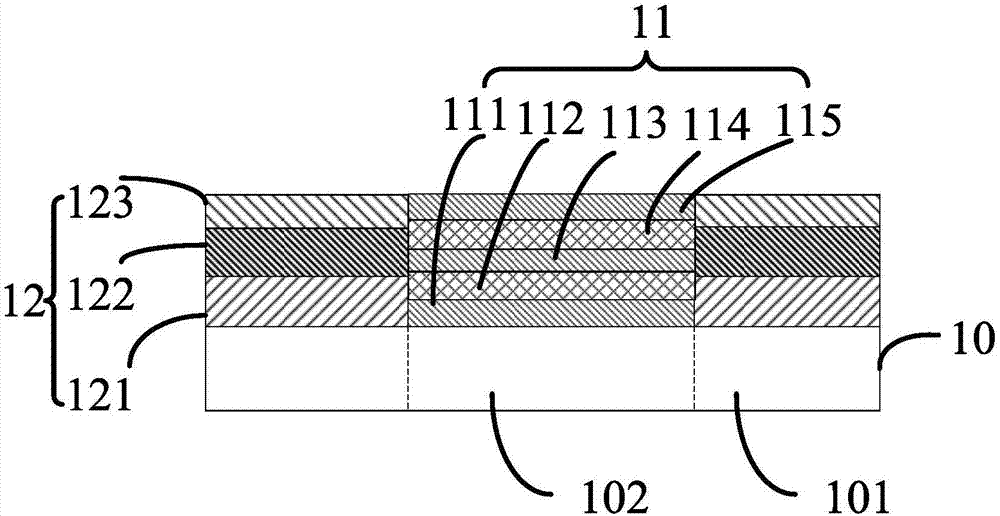

[0019] refer to figure 1 , an embodiment of the flexible display component of the present invention includes a display layer 10 , a first film layer 11 and a second film layer 12 . The display layer 10 includes a non-bending area 101 and a bending area 102 . The first thin film layer 11 at least includes a first inorganic layer 111 and a first organic layer 112 sequentially formed on the bending region 102 . The second thin film layer 12 at least includes a second inorganic layer 121 and a second organic layer 122 sequentially formed on the non-bending region 101 .

[0020] Wherein, the modulus difference between the first inorganic layer 111 and the display layer 10 is smaller than the modulus difference between the second inorganic layer 121 and the display layer 10, and / or the thickness d of the first inorganic layer 111 is smaller than that of the second inorganic layer 121 Thickness D. The thickness of the first thin film layer 11 is equal to the thickness of the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com