Method for quickly preparing metal ceramic coating through laser induced composite fusioncast

A metal-ceramic coating and laser induction technology, which is applied in metal material coating process, coating, air transportation, etc., can solve the problems of easy cracking of metal-ceramic coating, small ceramic phase injection depth, and low volume percentage , to achieve excellent wear resistance, high volume percentage, and low burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

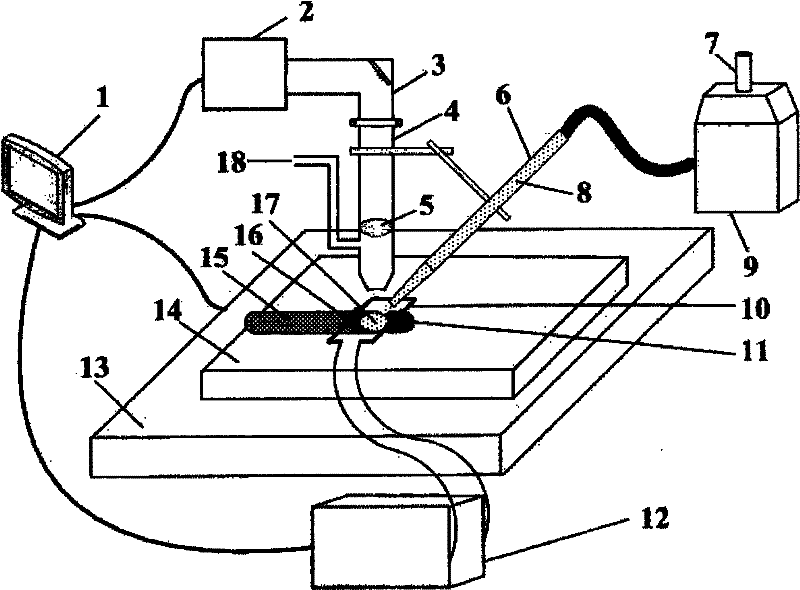

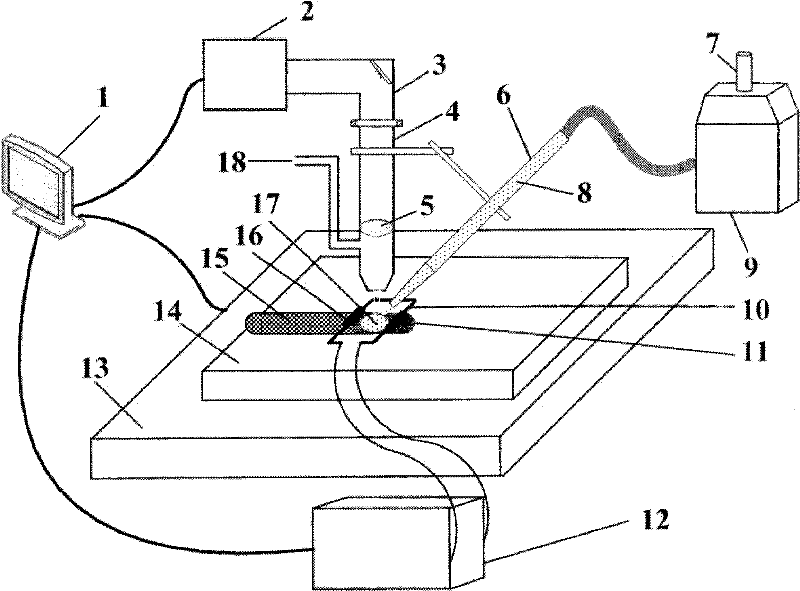

Method used

Image

Examples

example 1

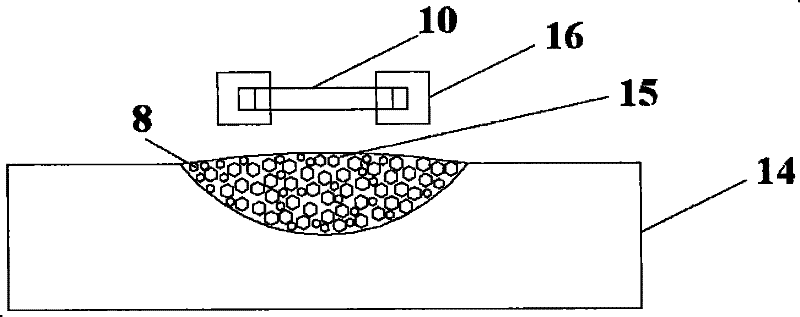

[0039] Using the method of laser induction compound fusion injection, cast WC particles are directly injected into the surface of nickel superalloy GH4133 to form WC / Ni cermet coating. The volume percentage of WC particles in the cermet coating is 30%, the injection depth of WC particles is 0.8mm, and the area of the coating is 100×150mm 2 .

[0040] The implementation process of this embodiment is:

[0041] (1) Selection of ceramic phase particles and preparation of substrate. Ceramic phase 8 is cast WC particles, composed of flaky WC+W 2 C has a crystal composition and an average particle size of 40 μm. It is placed in an incubator at 150° C. to dry for 2 hours, and then put into the loading hopper 7 of the automatic powder feeder 9 . The base material 14 is a nickel-based superalloy GH4133, and its chemical composition is (mass percentage) 0.032-0.038%C, 19-22%Cr, 0.05-0.07Si, 0.01-0.03Mn, 0.8-1.2%Al, 2.5-3% Ti, 1.2 ~ 1.4Nb, 0.002 ~ 0.003B, 0.01 ~ 0.02Fe, the balance ...

example 2

[0048] Using the method of laser induction composite melting injection, the MoSi 2 Particles are directly injected into the surface of TC4 alloy to form MoSi 2 / Ti cermet coating. The MoSi within the cermet coating 2 The volume percentage of particles is 50%, MoSi 2 The injection depth of the particles is 1.2mm, and the coating area is 120×180mm 2 .

[0049] The implementation process of this embodiment is:

[0050] (1) Selection of ceramic phase particles and preparation of substrate. Ceramic phase 8 is MoSi 2 The particles, whose average particle size is 50 μm, were placed in an incubator at 150° C. to dry for 2 hours, and then put into the hopper 7 of the automatic powder feeder 9 . The base material 14 is a TC4 alloy, its chemical composition is (mass percentage) 5.5-6.0% Al, 3.5-4.5% V, and the balance is Ti, and its surface is ready for use after derusting, degreasing, cleaning and sandblasting;

[0051] (2) The distance between the surface of the base material T...

example 3

[0057] Al 2 o 3 Particles are directly injected into the surface of cast aluminum alloy (Al-7wt.%Si) 2 o 3 / Al-Si cermet coating. Al in the cermet coating 2 o 3 The volume percentage of particles is 70%, Al 2 o 3The injection concentration depth of the particles is 2mm, and the coating area is 150×200mm 2 .

[0058] The implementation process of this embodiment is:

[0059] (1) Selection of ceramic phase particles and preparation of substrate. Ceramic phase 8 is Al 2 o 3 The particles, whose average particle size is 60 μm, were placed in an incubator at 150° C. to dry for 2 hours, and then put into the loading hopper 7 of the automatic powder feeder 9 . The base material 14 is cast aluminum alloy (Al-7wt.% Si), and its surface is ready for use after derusting, degreasing, cleaning and sandblasting;

[0060] (2) Adjust the distance between the surface of the base material casting aluminum alloy (Al-7wt.% Si) 14 and the induction heating coil 10 to 8mm, feed the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com