Treatment machine for preventing moth and mildew of bamboo and wood

A moth-proof, mildew-proof, and treatment agent technology, which is applied in wood treatment, wood treatment details, impregnated wood, etc., can solve the problems of difficult control of injection volume, difficult control of injection depth, and difficulty in injection, etc., to achieve simple structure, The effect of easy injection and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

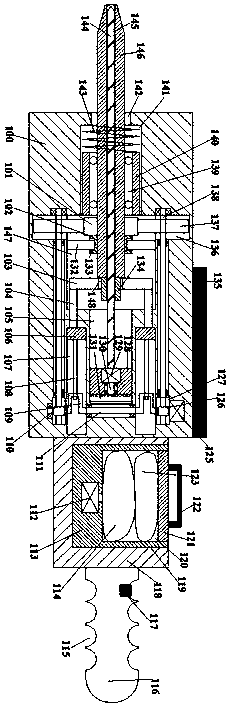

[0015] like figure 1As shown, a bamboo and wood anti-mold and anti-mildew treatment agent of the present invention includes a fuselage 100 and a first cavity 147 arranged in the fuselage 100, and the inner wall of the right end of the first cavity 147 communicates with the inner wall. There is a first guide chute 105, the upper and lower ends of the first guide chute 105 are provided with a symmetrical second guide chute 107, and the end of the second guide chute 107 is far away from the end of the first guide chute 105. The second cavity 127, the inner wall of the upper and lower ends of the first cavity 147 is communicated with a third cavity 136, the inner wall of the left end of the first cavity 147 is communicated with a third guide groove 141, and the third cavity 147 is communicated with a third guide groove 141. An opening 142 is provided in the left end wall of the guide chute 141, and a first guide slider 140 is slidably connected in the third guide chute 141, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com