BiPO4 nanorod and preparation method and application thereof

A nanorod and reaction technology, which is applied in the field of photocatalytic materials, can solve the problems of variable pressure environment, low single preparation at high temperature, etc., and achieve the effects of good ultraviolet photocatalytic activity, cheap raw materials, and reduced product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

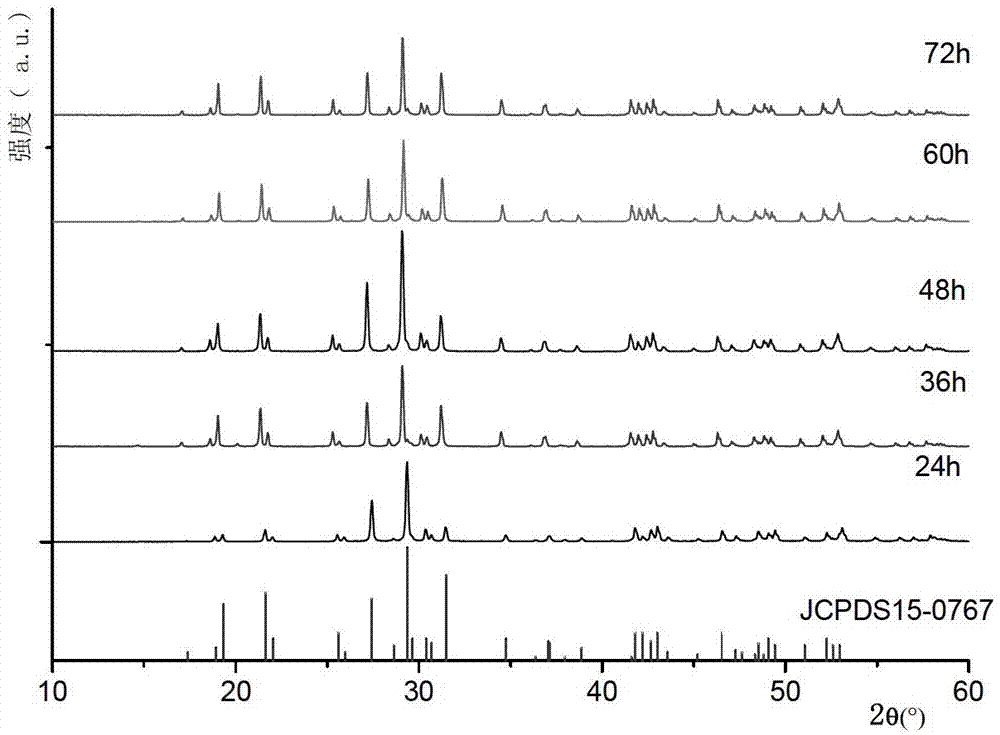

[0022] Example 1, adjusting the reaction time to prepare BiPO 4 Nano stave

[0023] Weigh 24.3g (50mmol) of Bi(NO 3 ) 3 ·5H 2 O and 7.8g (50mmol) of NaH 2 PO 4 2H 2 O, add 5.0L three-necked flask, measure 3.6L deionized water and join in the three-necked flask, then put the magnet into the three-necked flask. The spherical condenser is connected to a small mouth of the three-necked flask, and the temperature sensor of the electric heating jacket is inserted into the reaction solution from the other small mouth of the three-necked flask, and the big mouth in the middle of the three-necked flask is plugged tightly with a stopper. Adjust the magnetic stirring knob on the electric heating mantle to 800r / min, and set the temperature of the electric heating mantle temperature control panel to 100°C. After heating for about 30 min, the reaction solution began to boil. Timing control reaction time is 24h, 36h, 48h, 60h and 72h from the time when the reaction solution boils (5...

Embodiment 2

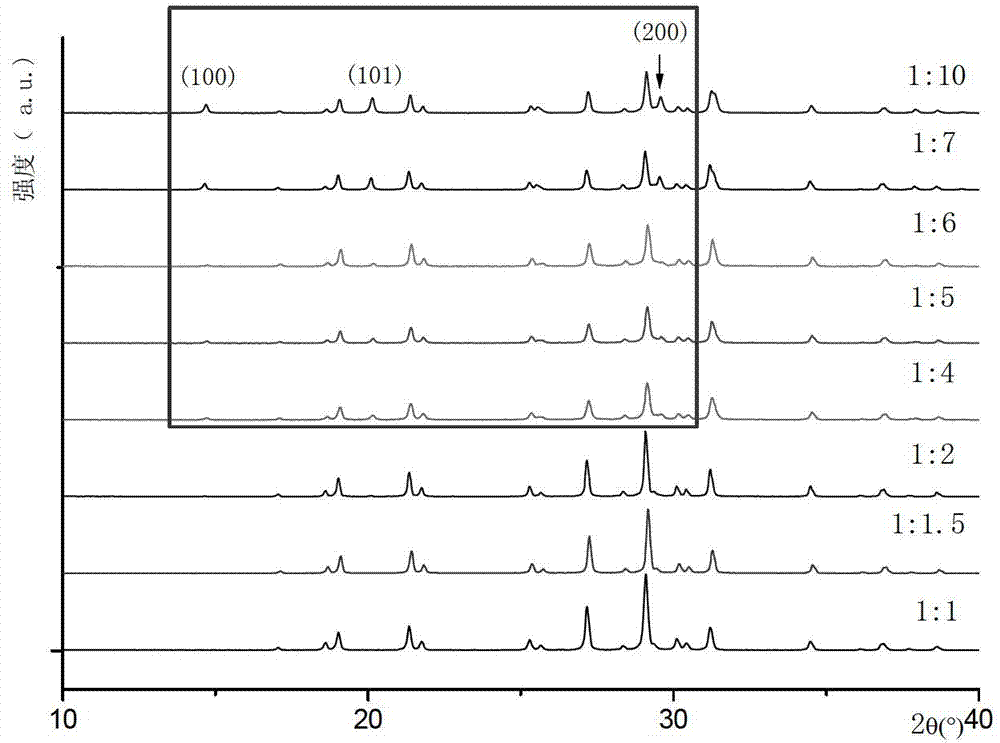

[0025] Embodiment 2, regulation and control Bi 3+ / PO 4 3- Ratio-prepared BiPO 4 Nano stave

[0026] Weigh 24.3g (50mmol) of Bi(NO 3 ) 3 ·5H 2 O and 39.0 g (250 mmol) of NaH 2 PO 4 2H 2 O, Bi 3+ / PO 4 3- The molar ratio is 1:5 (fixed Bi(NO 3 ) 3 ·5H 2 The amount of O is 50mmol, and the regulation of Bi 3+ / PO 4 3-The molar ratios were 1:1, 1:1.5, 1:2, 1:4, 1:5, 1:6, 1:7 and 1:10, and a total of 8 groups of experiments were done, and NaH was weighed according to different ratios. 2 PO 4 2H 2 The amount of O is respectively 7.8g, 11.7g, 15.6g, 31.2g, 46.8g, 54.6g and 78.0g), add a 5.0L three-necked flask, measure 3.6L deionized water into the three-necked flask, and then put the magnetic into a three-neck flask. Connect the spherical condenser to a small mouth of the three-necked flask, insert the temperature sensor of the electric heating mantle into the reaction solution from the other small mouth of the three-necked flask, and plug the middle big mouth o...

Embodiment 3

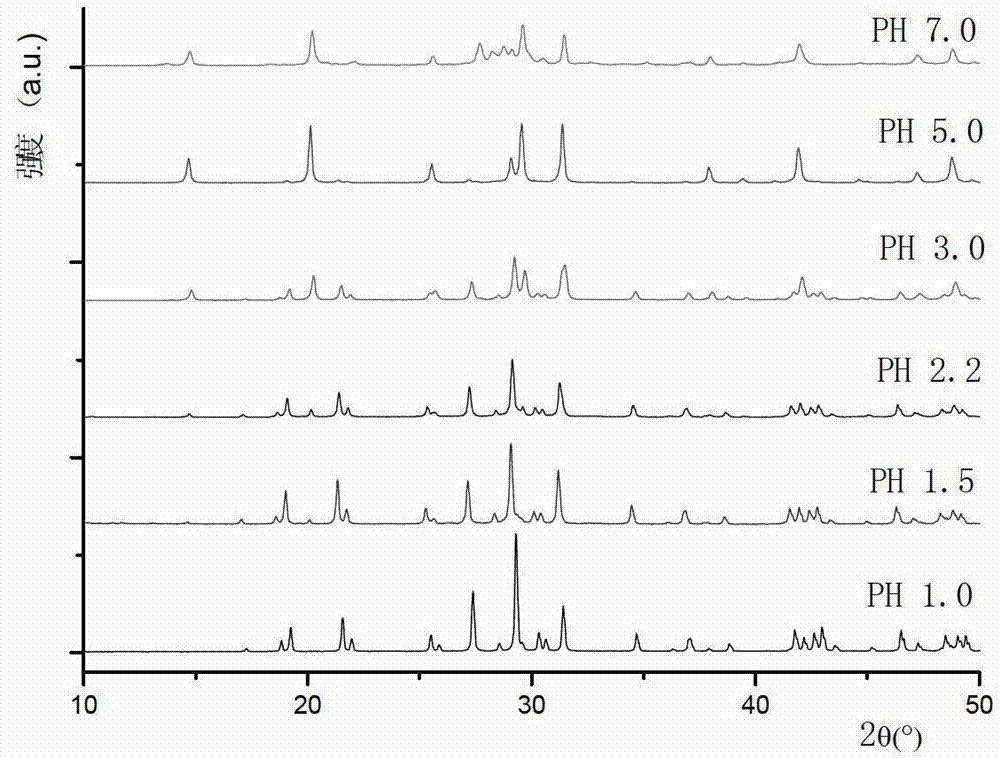

[0028] Example 3, adjusting the pH value of the reaction solution to prepare BiPO 4 Nano stave

[0029] Weigh 24.3g (50mmol) of Bi(NO 3 ) 3 ·5H 2 O and 39.0 g (250 mmol) of NaH 2 PO 4 2H 2 O, Bi 3+ / PO 4 3- The molar ratio is 1:5, put into a 5.0L three-necked flask, measure 3.6L deionized water into the three-necked flask, and then put the magnet into the three-necked flask. Adjust the magnetic stirring knob on the electric heating mantle to 800r / min, measure the pH value of the reaction mixture with a pHSJ-4A pH meter at room temperature to 2.2, and use concentrated HNO 3 Adjust the pH of the reaction mixture to 1.0 and 1.5, and use 1.0mol / L NaOH solution to adjust the pH of the reaction mixture to 3.0, 5.0 and 7.0 (6 groups of tests were done in total). After the pH value of the reaction solution is adjusted to an appropriate value, connect the spherical condenser tube to one mouth of the three-necked flask, and insert the temperature sensor of the electric heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com