Preparation method and application of SbPO4 microsphere

A microsphere, hydrothermal method, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems that have not yet been discovered, and achieve short reaction time, mild reaction conditions, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a SbPO 4 The preparation method of microspheres is synthesized by ionic liquid-assisted hydrothermal method, comprising the following steps:

[0027] (1) Dissolve 0.001mol ionic liquid ([BMIM]P) in 15mL deionized water under magnetic stirring, and stir for 10min to dissolve completely;

[0028] (2) Under magnetic stirring, 0.002mol SbCl 3 Dissolve in the solution prepared in step 1, and stir for 30 minutes to obtain the precursor;

[0029] (3) Transfer the above-mentioned precursors to the reactor, the volume filling volume of the precursor is 80%, seal the reactor and place it in an oven, the reaction temperature is 160°C, and the reaction time is 24h;

[0030] (4) After the reaction, wash with absolute ethanol and deionized water for 3 times, and finally dry at 70°C for 12 hours to obtain SbPO 4 Microspheres.

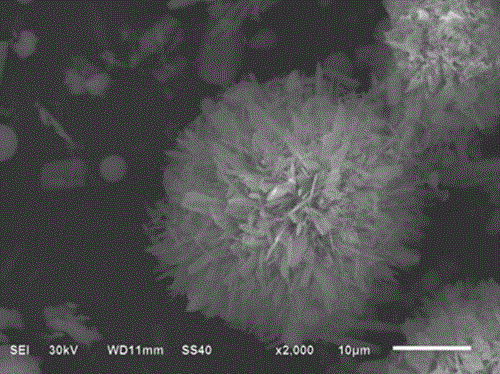

[0031] Depend on figure 1 The resulting SbPO 4 The SEM image of the microspheres, it can be seen that the SbPO prepared under this condition 4 The diame...

Embodiment 2

[0033] a SbPO 4 The preparation method of microspheres is synthesized by ionic liquid-assisted hydrothermal method, comprising the following steps:

[0034] (1) Dissolve 0.002mol ionic liquid ([BMIM]P) in 15mL deionized water under magnetic stirring, and stir for 10min to dissolve completely;

[0035] (2) Under magnetic stirring, 0.002mol SbCl 3 Dissolve in the solution prepared in step 1, and stir for 30 minutes to obtain the precursor;

[0036] (3) Transfer the above-mentioned precursors to the reactor, the volume filling volume of the precursor is 80%, seal the reactor and place it in an oven, the reaction temperature is 160°C, and the reaction time is 24h;

[0037] (4) After the reaction, wash with absolute ethanol and deionized water for 3 times, and finally dry at 70°C for 12 hours to obtain SbPO 4 Microspheres.

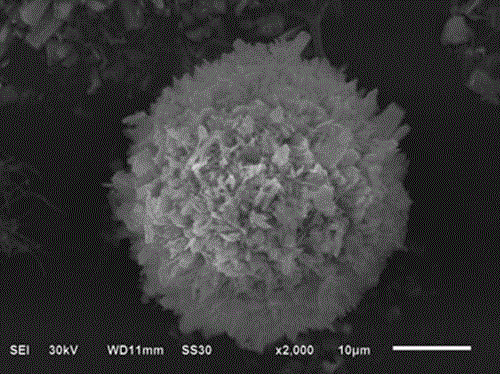

[0038] Depend on figure 2 The resulting SbPO 4 The SEM image of the microspheres, it can be seen that the SbPO prepared under this condition 4 The diam...

Embodiment 3

[0041] a SbPO 4 The preparation method of microspheres is synthesized by ionic liquid-assisted hydrothermal method, comprising the following steps:

[0042] (1) Dissolve 0.003mol ionic liquid ([BMIM]P) in 15mL deionized water under magnetic stirring, and stir for 10min to dissolve completely;

[0043] (2) Under magnetic stirring, 0.002mol SbCl 3 Dissolve in the solution prepared in step 1, and stir for 30 minutes to obtain the precursor;

[0044] (3) Transfer the above-mentioned precursors to the reactor, the volume filling volume of the precursor is 80%, seal the reactor and place it in an oven, the reaction temperature is 160°C, and the reaction time is 24h;

[0045] (4) After the reaction, wash with absolute ethanol and deionized water for 3 times, and finally dry at 70°C for 12 hours to obtain SbPO 4 Microspheres.

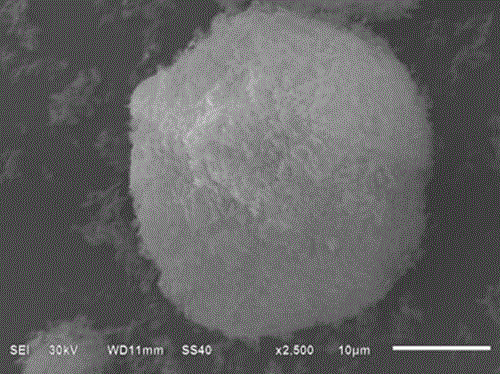

[0046] Depend on image 3 The resulting SbPO 4 The SEM image of the microspheres, it can be seen that the SbPO prepared under this condition 4 The diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com