A kind of lanthanum-cerium co-doped isotropic bonded magnetic powder and preparation method thereof

An isotropic, magnetic powder technology, used in magnetic objects, magnetic materials, electrical components, etc., can solve problems such as consumption, soaring prices, and resource shortages, and achieve uniform morphology distribution, production cost reduction, and grain refinement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Another aspect of the present invention also provides a method for preparing isotropic bonded magnetic powder co-doped with lanthanum and cerium, comprising the following steps:

[0055] (1) Weigh the raw material according to the composition in the magnetic powder and place it in the furnace to smelt it into a clarified alloy liquid, and cool it into an alloy ingot;

[0056] (2) Place the alloy ingot smelted in step (1) into an induction quick quenching furnace after being broken, and the quick quenching furnace is evacuated and filled with argon to a positive pressure, and the broken alloy is placed in the quick quenching furnace The crucible is melted to boiling to form alloy liquid, and then flows from the gate to the edge of the rotating roller, and the alloy liquid is rapidly cooled and solidified into a thin strip under the cooling action of the roller;

[0057] (3) heat-treating the rapidly quenched ribbon obtained in step (2) and quenching, and breaking the rib...

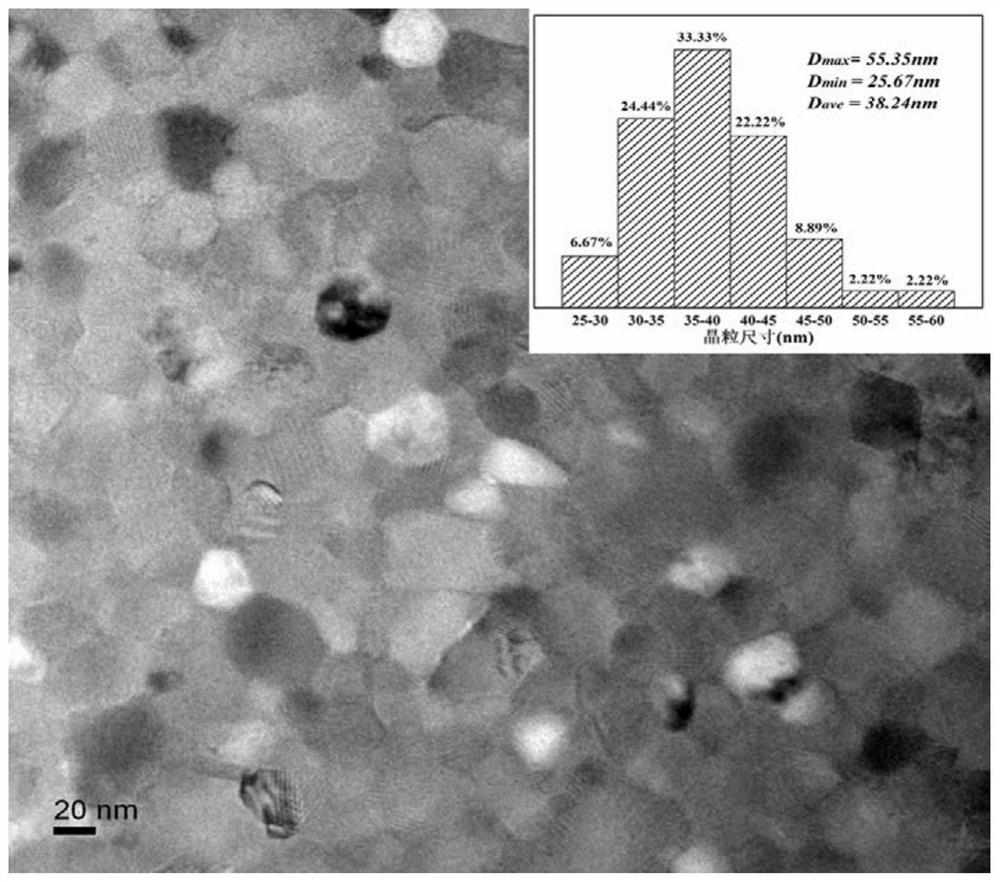

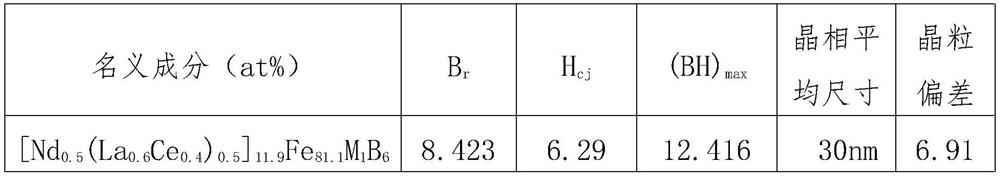

Embodiment 1

[0092] The permanent magnetic material prepared by the present embodiment has the following alloy composition: [Nd 0.5 (La 0.6 Ce 0.4 ) 0.5 ] 11.9 Fe 81.1 m 1 B 6 , M is Al and / or Nb, and the contents of the above-mentioned elements are in atomic percent. Specific steps are as follows:

[0093] (1) a master alloy equipped with the above-mentioned composition, wherein the raw materials La, Ce, and Nd are all added in the form of pure metal, and the phase form of B is respectively a BFe alloy containing 20 atomic percent of B and 80 atomic percent of Fe, The amount of remaining Fe is formulated as pure metal. Then adopt the following process steps to manufacture NdFeB rare earth permanent magnet materials.

[0094] (2) Put the raw material in a vacuum induction furnace to melt into a clarified alloy liquid, turn off the current and rapidly cool it under circulating cold water at 20°C to form an alloy ingot.

[0095] (3) Place the above-mentioned smelted alloy ingot in ...

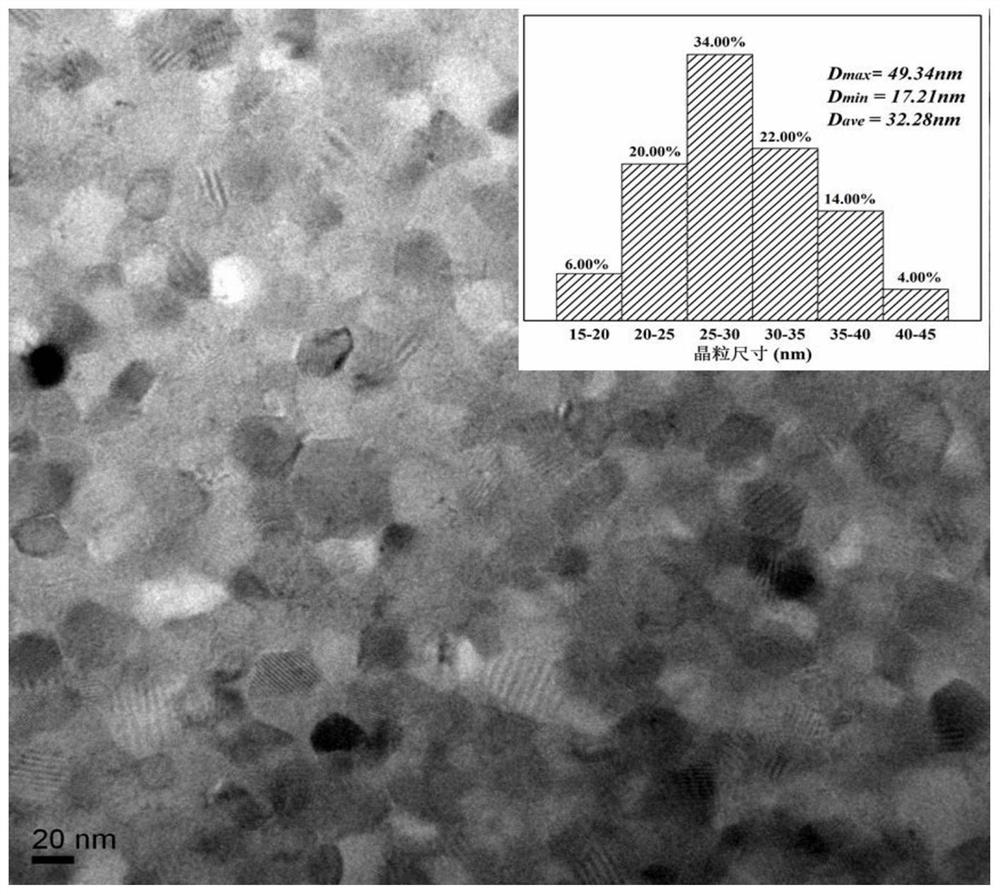

Embodiment 2

[0102] The permanent magnetic material prepared by the present embodiment has the following alloy composition: [Nd 0.6 (La 0.8 Ce 0.2 ) 0.4 ] 11.9 Fe 81.1 m 1 B 6 , M is Al and / or Nb, and the contents of the above-mentioned elements are in atomic percent. Specific steps are as follows:

[0103] (1) a master alloy equipped with the above-mentioned composition, wherein the raw materials La, Ce, and Nd are all added in the form of pure metal, and the phase form of B is respectively a BFe alloy containing 20 atomic percent of B and 80 atomic percent of Fe, The amount of remaining Fe is formulated as pure metal. Then adopt the following process steps to manufacture NdFeB rare earth permanent magnet materials.

[0104] (2) Melt the raw materials in a vacuum induction furnace to form a clarified alloy solution, then turn off the current and rapidly cool it under circulating cold water at 23°C to form an alloy ingot.

[0105] (3) Place the above-mentioned smelted alloy ingot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com