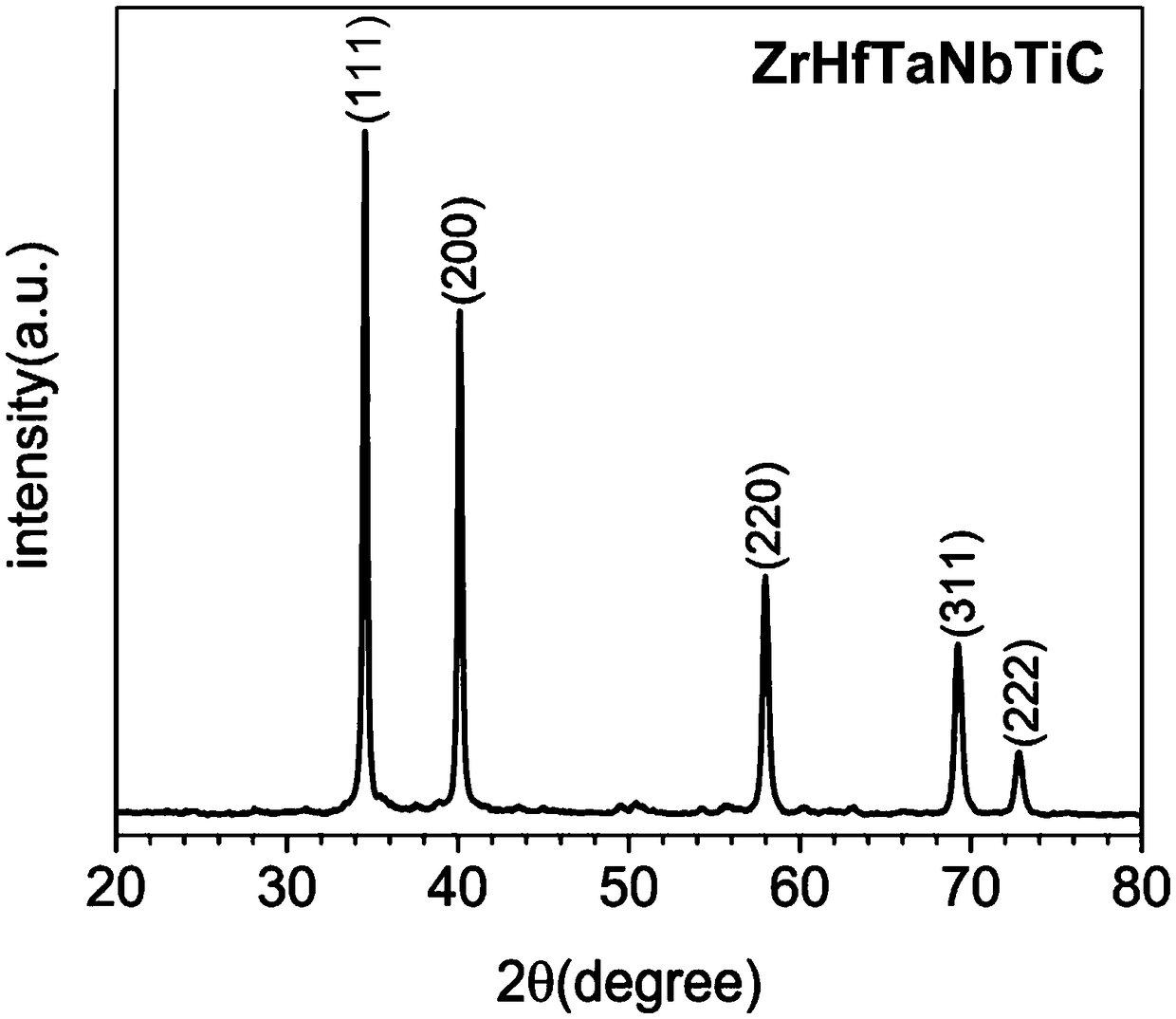

ZrHfTaNbTiC ultrahigh-temperature high-entropy ceramic material as well as preparation method thereof

A ceramic material and ultra-high temperature technology, which is applied in the field of ultra-high temperature materials and their preparation, can solve the problems of poor mechanical properties of materials, high pressure required, and low sintering temperature, and achieve thermodynamic stability, good mechanical properties, and low preparation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of ZrHfTaNbTiC ultra-high temperature high-entropy ceramic material, the specific steps are as follows:

[0032] (1) Weigh the powders of 10.3g ZrC, 19.1g HfC, 19.3g TaC, 10.5g NbC and 6.1g TiC respectively, pour them into a PTFE ball mill jar, and take and mix with ZrC, HfC, TaC, NbC and TiC The agate balls whose mixed material volume ratio is 2:1 are put into a ball mill jar, then poured into 30ml of absolute ethanol, and with a planetary ball mill, ball milled for 6h at a speed of 500r / min to obtain a homogeneously mixed suspension;

[0033] (2) Transfer the obtained suspension to an eggplant-shaped flask and install it into a rotary steaming system, and rotate it at 60°C for 1 hour to obtain a semi-dry powder that is uniformly mixed, and then place the semi-dry powder in a drying oven Dry at 70°C for 12 hours, place it in an agate mortar and grind it by hand for 10 minutes and pass through a 200-mesh sieve to obtain a powder to be fired;

[0034] (3) Tr...

Embodiment 2

[0037] Preparation of ZrHfTaNbTiC ultra-high temperature high-entropy ceramic material, the specific steps are as follows:

[0038](1) Weigh the powders of 1g ZrC, 10g HfC, 10g TaC, 1.33g NbC and 2.21g TiC respectively, pour them into a PTFE ball mill jar, and take the mixed materials with ZrC, HfC, TaC, NbC and TiC Put agate balls with a volume ratio of 2:1 into a ball mill jar, then pour 35ml of absolute ethanol, and use a planetary ball mill to mill for 16 hours at a speed of 500r / min to obtain a uniformly mixed suspension;

[0039] (2) Transfer the obtained suspension to an eggplant-shaped flask and install it into a rotary steaming system, and rotate it at 60°C for 2 hours to obtain a semi-dry powder that is uniformly mixed, and then place the semi-dry powder in a drying box Dry at 80°C for 16 hours, place it in an agate mortar and grind it by hand for 20 minutes and pass through a 200-mesh sieve to obtain the ceramic powder to be fired;

[0040] (3) Transfer the ceramic...

Embodiment 3

[0042] Preparation of ZrHfTaNbTiC ultra-high temperature high-entropy ceramic material, the specific steps are as follows:

[0043] (1) Weigh the powders of 5g ZrC, 5g HfC, 5g TaC, 5g NbC and 5g TiC respectively, pour them into a polytetrafluoroethylene ball mill jar, and take the volume ratio of the mixed material with ZrC, HfC, TaC, NbC and TiC Put the agate balls at a ratio of 2:1 into a ball mill jar, then pour 40ml of absolute ethanol, and use a planetary ball mill to mill for 24 hours at a speed of 500r / min to obtain a uniformly mixed suspension;

[0044] (2) Transfer the obtained suspension to an eggplant-shaped flask and install it into a rotary steaming system, and rotate it at 60°C for 3 hours to obtain a semi-dry powder that is uniformly mixed, and then place the semi-dry powder in a drying oven Dry at 90°C for 24 hours, place it in an agate mortar and grind it by hand for 30 minutes and pass through a 200-mesh sieve to obtain a powder to be fired;

[0045] (3) Tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com