Three-dimensional alumina fiber fabric reinforced oxide ceramic and preparation method thereof

A technology of alumina fiber and oxide ceramics, which is applied in the field of three-dimensional alumina fiber fabric reinforced oxide ceramics and its preparation, can solve the problems of aggravated fiber thermal damage, high sintering temperature, and difficulty in forming three-dimensional complex structures, so as to improve mechanical properties The effect of performance, low preparation temperature, and easy molding of three-dimensional complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

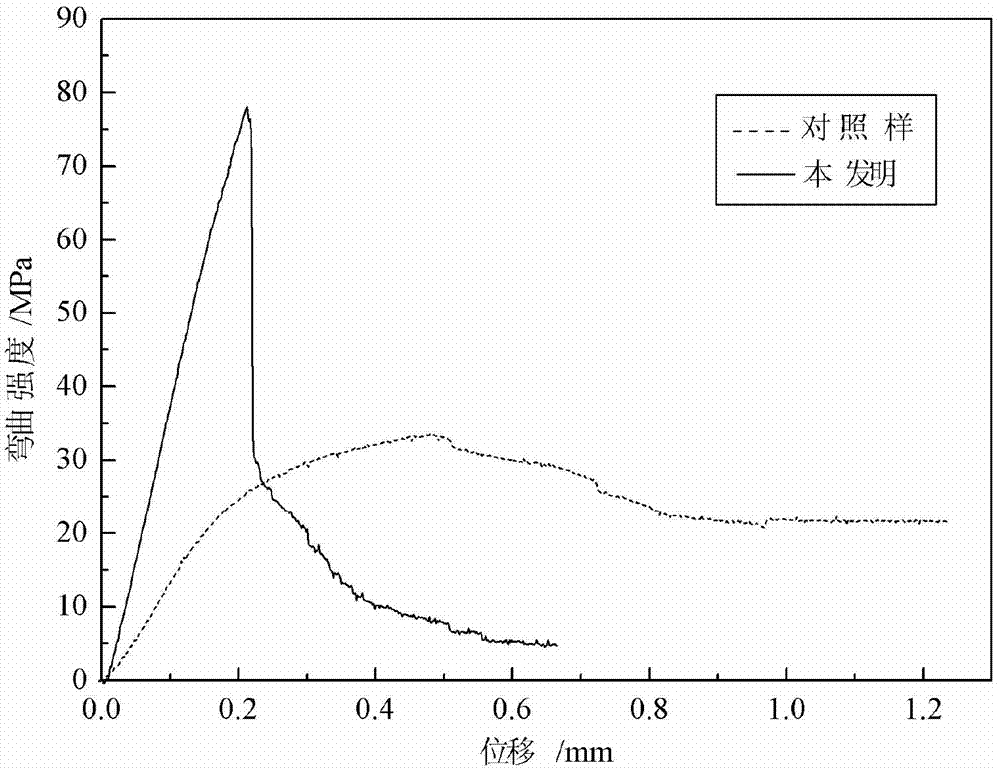

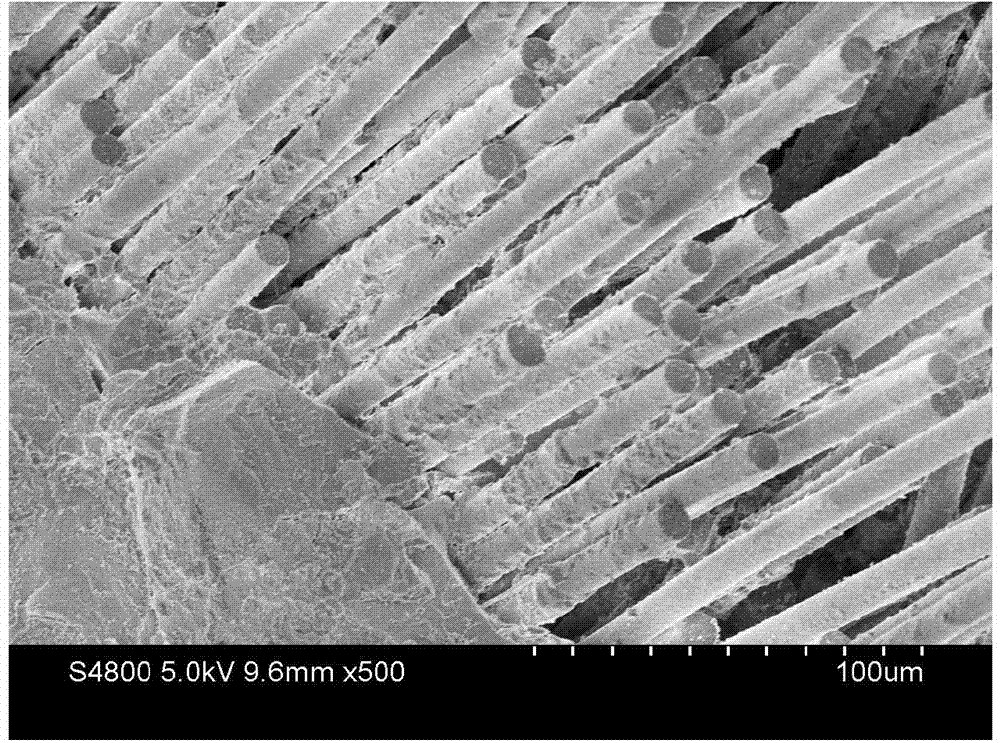

[0035] a kind of like figure 1 The three-dimensional alumina fiber fabric reinforced oxide ceramics of the present invention shown, the ceramics are based on Al 2 o 3 , SiO 2 and SiOC ceramics as the matrix, and a three-dimensional alumina fiber fabric with a volume fraction of 40% as the reinforcement. Al in matrix 2 o 3 and SiO 2 is introduced through the sol-gel process to form porous Al 2 o 3 -SiO 2 Composite matrix, SiOC ceramics are mainly filled with Al after pyrolysis of polysiloxane 2 o 3 -SiO 2 obtained in the pores of the composite matrix; Al 2 o 3 -SiO 2 The volume fraction of the composite matrix is 30%, the volume fraction of SiOC ceramics is 12%, and the rest are pores. Among them, Al in the matrix 2 o 3 and SiO 2 It is obtained by transformation of oxide sol with a solid phase content of 32% (AS21 silicon-aluminum composite sol, produced by Suzhou Nadi Microelectronics Co., Ltd.), and SiOC ceramics are obtained by transformation of polysiloxa...

Embodiment 2

[0048] A kind of three-dimensional alumina fiber fabric of the present invention strengthens oxide ceramics, and this ceramics is based on Al 2 o 3 , SiO 2 and SiOC ceramics as the matrix, and a three-dimensional alumina fiber fabric with a volume fraction of 41% as the reinforcement. Al in matrix 2 o 3 and SiO 2 is introduced through the sol-gel process to form porous Al 2 o 3 -SiO 2 Composite matrix, SiOC ceramics are mainly filled with Al after pyrolysis of polysiloxane 2 o 3 -SiO 2 obtained in the pores of the composite matrix; Al 2 o 3 -SiO 2 The volume fraction of the composite matrix is 26%, the volume fraction of SiOC ceramics is 8%, and the rest is pores. Among them, Al in the matrix 2 o 3 and SiO 2 It is obtained by converting an oxide sol with a solid content of 33.5%, and the SiOC ceramic in the matrix is obtained by converting a polysiloxane-ethanol solution with a mass concentration of 60%.

[0049] A method for preparing the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com