Preparation process of tungsten carbide/inhibitor composite powder and superfine hard alloy thereof

A technology of composite powder and cemented carbide, which is applied in the field of preparation of tungsten carbide-based ultrafine cemented carbide, can solve problems such as limiting carbonization temperature, and achieve the effects of low production cost, simple and safe process, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

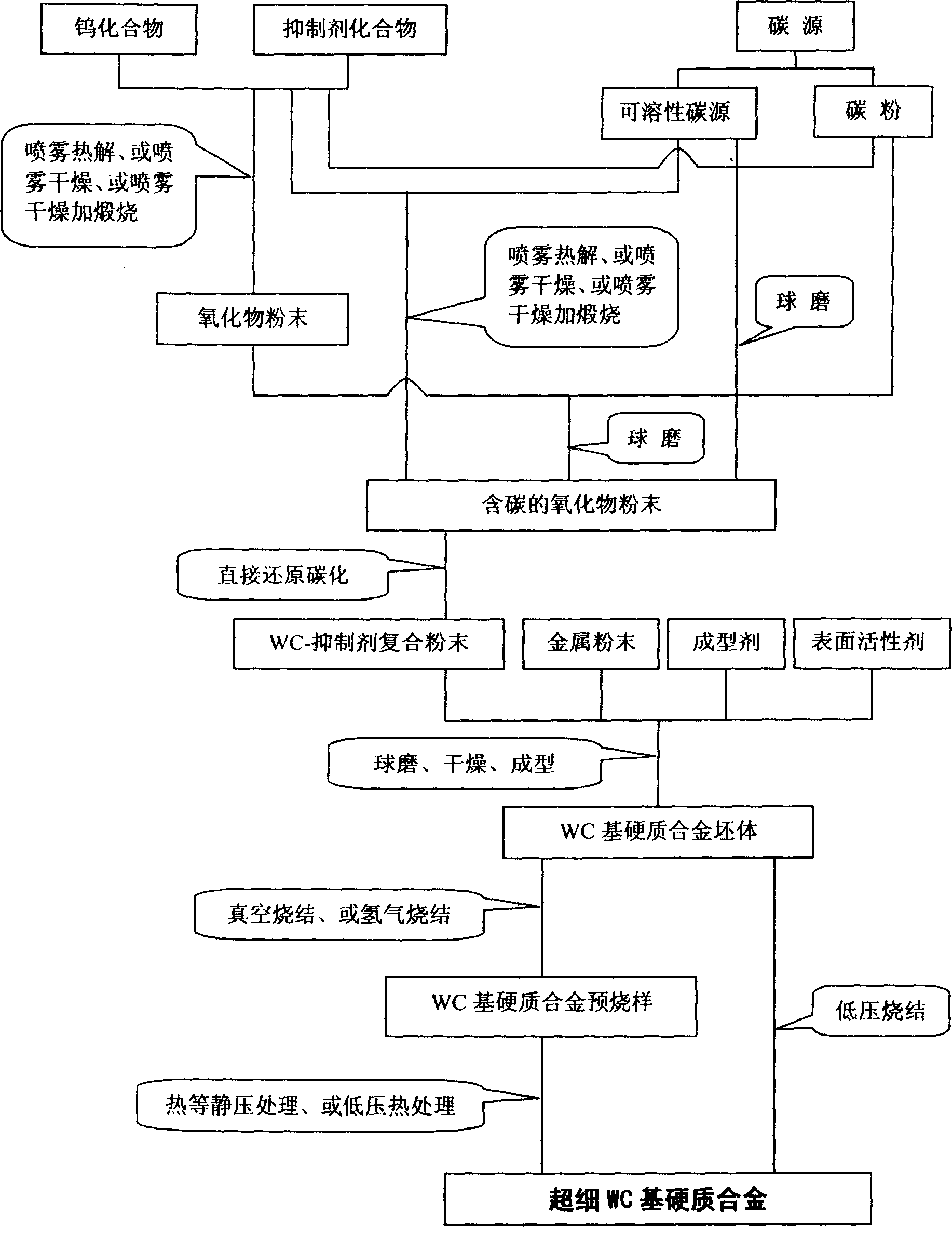

Method used

Image

Examples

Embodiment 1

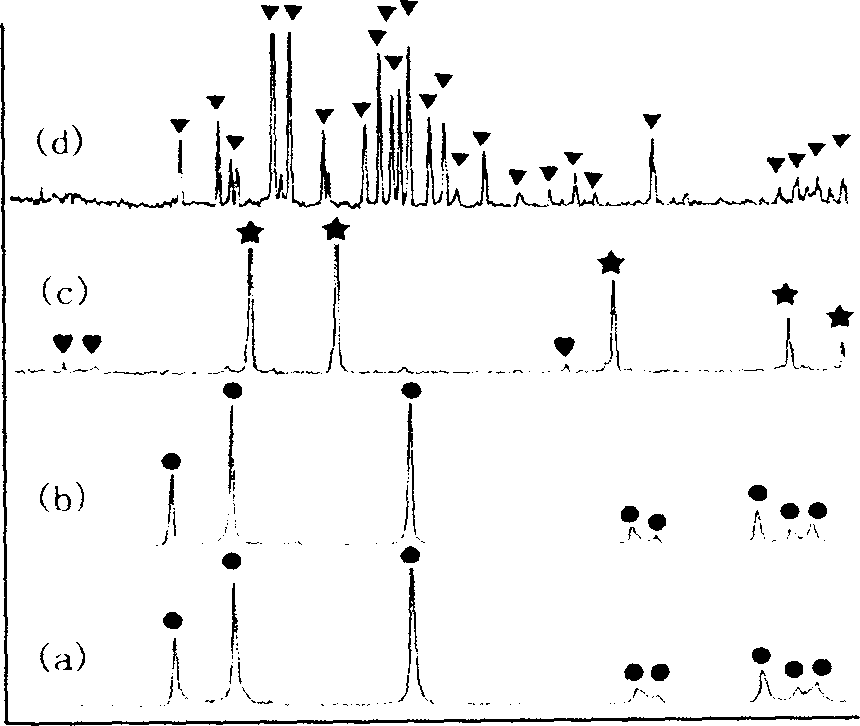

[0051] Embodiment 1: ammonium metatungstate AMT ((NH 4 ) 6 (H 2 W 12 o 40 )·4H 2 O), ammonium metavanadate (NH 4 VO 3 ), ammonium dichromate ((NH 4 ) 2 Cr 2 o 7 ) is miscible in distilled water at a mass ratio of 100:0.66:0.74, and is made into oxide powder by spray pyrolysis. The oxide powder and carbon powder were weighed according to the mass ratio W: C=3.83:1, V: C=1.21:1, Cr: C=2.00:1, and put into a roller mill for dry grinding for 72 hours (material: ball =1:2), the resulting mixed powder was carbonized in a tube furnace in an argon atmosphere at 1350°C for 0.5 hours, and then cooled to room temperature in argon. At the same time a comparative experiment was carried out in this furnace: using WO 3 +C, V 2 o 5 +C, Cr 2 o 3 +C are three additionally prepared raw materials, wherein the ratio of tungsten, vanadium, chromium and carbon all follows the ratio of this embodiment. The XRD pattern of the carbonized powder is shown in the appendix of the instructi...

Embodiment 2

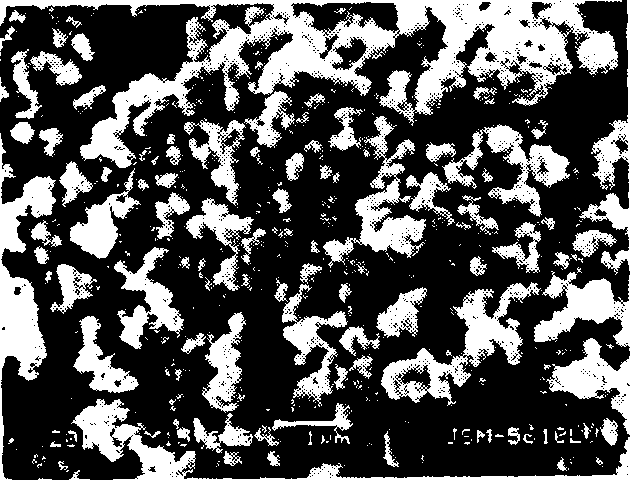

[0052] Embodiment 2: ammonium paratungstate APT ((NH 4 ) 10 (H 2 W 12 o 42 )·4H 2 O), ammonium metavanadate (NH 4 VO 3 ), ammonium dichromate ((NH 4 ) 2 Cr 2 o 7 ) is miscible in distilled water according to the mass ratio of 100:0.44:0.50, and is made into oxide powder by centrifugal pressure spray drying. W: C = 3.83: 1, V: C = 1.21: 1, Cr: C = 2.00: 1 Weigh it, put it into a roller ball mill, and use absolute alcohol as the medium for wet grinding for 48 hours (material: ball: liquid = 1 : 3: 0.8), the mixed powder obtained after drying was carbonized at 1000° C. for 12 hours in a rotary furnace in a nitrogen atmosphere, and then cooled to room temperature in a nitrogen atmosphere. The characteristic parameters of the WC-inhibitor composite powder made by testing are: tungsten content W=93.27wt%, C t = 6.15wt%, C f =0.05wt%, O=0.10wt%, other metal element content=0.43wt%, BET=2.62m 2 / g. Add cobalt powder (Fess=0.6 μm, 10wt%) and appropriate amount of carbon ...

Embodiment 3

[0053] Embodiment 3: ammonium metatungstate AMT ((NH 4 ) 6 (H 2 W 12 o 40 )·4H 2 O), ammonium metavanadate (NH 4 VO 3 ) is miscible in distilled water according to the mass ratio of 100:1.03, and is spray-dried by centrifugal pressure to make oxide powder. =3.83:1, V:C=1.21:1 weighed, put into a ball mill, wet milled with acetone as a medium for 48 hours (material: ball: liquid=1:4:0.8), the mixed powder obtained after drying Carburize in the furnace at 1300°C for 2 hours, then cool to room temperature with the furnace. The characteristic parameters of the WC-inhibitor composite powder made by testing are: tungsten content W=91.23wt%, C t = 6.45wt%, C f =0.04wt%, O=0.13wt%, other metal element content=2.15wt%, BET=2.66m 2 / g. Add diamond powder (Fess=1.0μm, 30wt%) and appropriate amount of carbon powder and molding agent to WC-inhibitor composite powder for ball milling, drying, molding, vacuum sintering (1250°C, 3h), hot isostatic pressing ( 1200°C, 1h, 200MPa), t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com