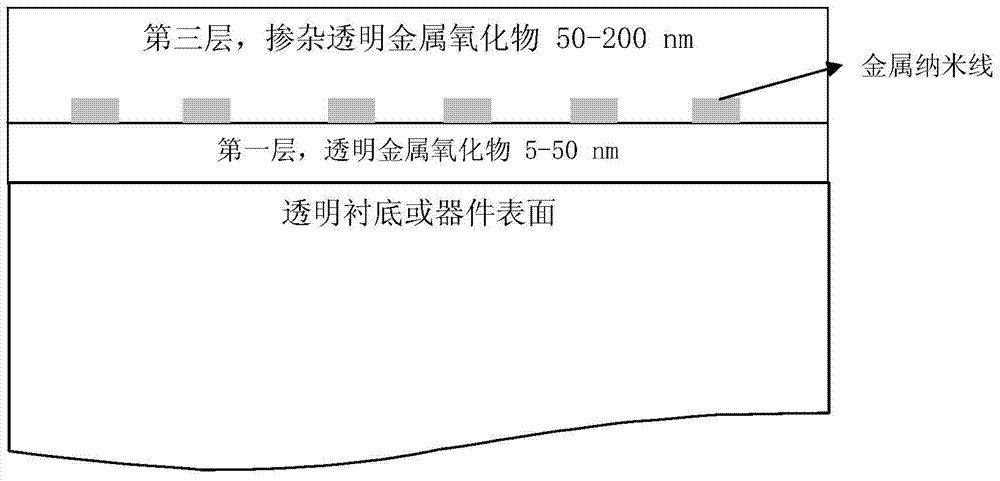

Laminated transparent electrode and preparation method thereof

A transparent electrode, lamination technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of weak adsorption force, large connection resistance, unsatisfactory transparent electrode materials and technology, etc., to achieve smooth surface, resistivity Effects of low, low preparation and growth temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

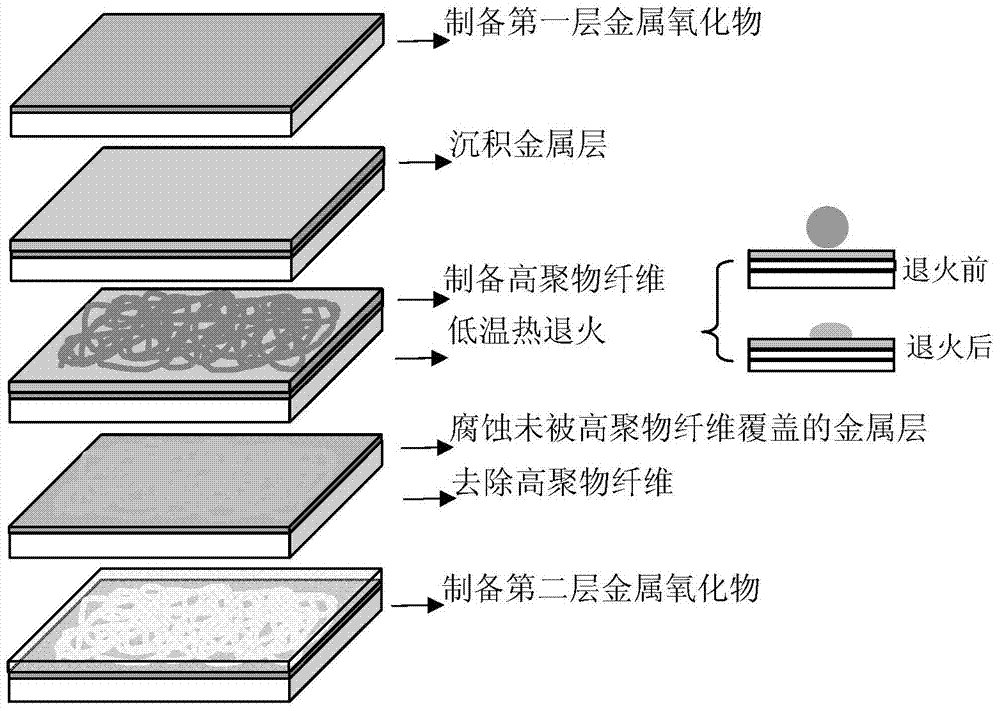

[0050] 1. First, degrease and clean the 4cm×4cm glass substrate according to the standard chemical cleaning procedure, and the cleaning agent used is a commercial common glass cleaning agent. After rinsing with deionized water, dry it in an oven at 150°C before use.

[0051] 2. At room temperature, utilize magnetron sputtering equipment to deposit a titanium dioxide film on the above-mentioned clean glass substrate. Wherein, the deposition power is 200 watts, the gas used for deposition is a mixture of argon and oxygen, and the corresponding flow ratio is 3:1. The deposition time is 2 minutes, and the thickness of the formed titanium dioxide film is 8nm;

[0052] 3. Deposit a 80nm copper layer on the surface of the titanium dioxide film by vacuum evaporation; when evaporating, the temperature of the glass substrate is controlled at 200°C by a heater. Film thickness can be controlled by film thickness monitoring device;

[0053] 4. Place the glass substrate on which the copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com