Supported nano TiO2 catalyst and preparation method thereof

A supported catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve catalyst adsorption and light absorption efficiency reduction, reduce catalyst activity, etc. problems, to achieve unique biocompatibility and degradability, controllable shape, high water holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

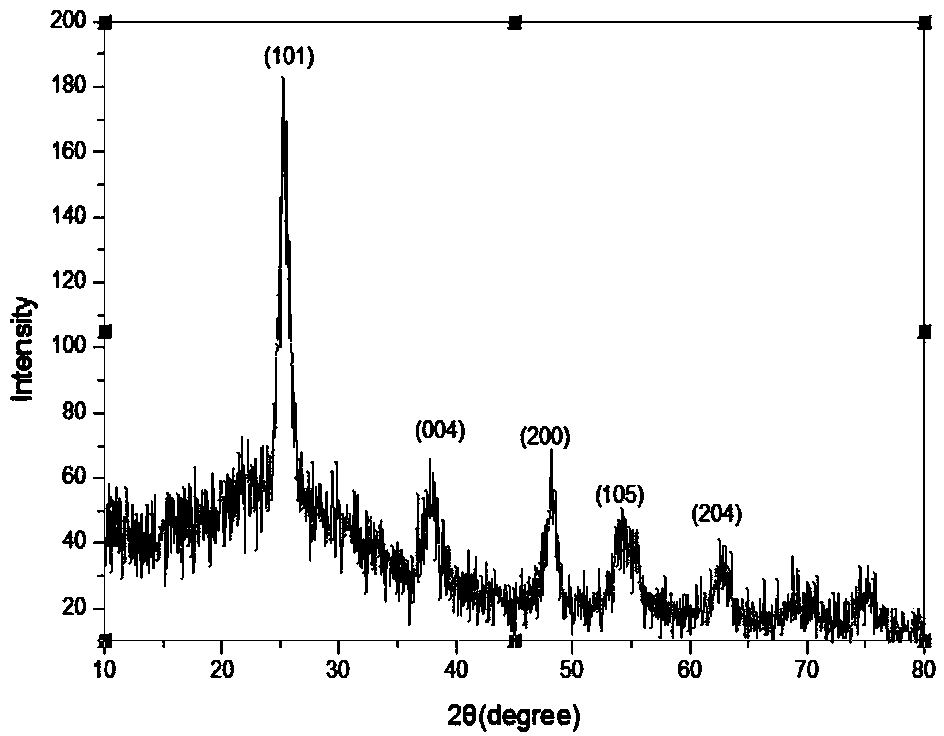

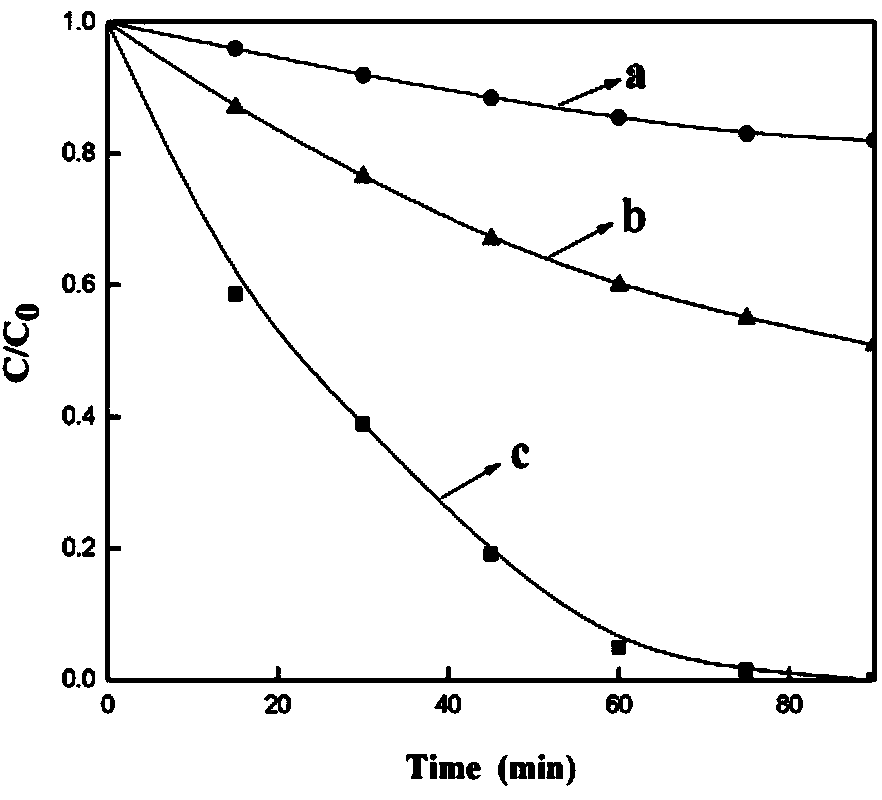

Image

Examples

Embodiment 1

[0032] The first step is to rinse the wet crude bacterial cellulose with 1‰ hydrogen peroxide, add it to 1% sodium hydroxide alkaline solution, heat and stir at 100°C for 12 hours, then neutralize it with acetic acid solution, and then wash it with deionized water until neutralized. sex;

[0033] In the second step, the bacterial cellulose obtained in the first step is soaked in a solution with an ethanol volume concentration of 50%, and then gradually increases the proportion of ethanol in the solution to 90%, and removes the bacteria on the surface of the bacterial cellulose through solvent exchange. Sequenced water, and finally centrifuged to separate the bacterial cellulose.

[0034] In the third step, use 99% ethanol solution as a solvent, add centrifuged bacterial cellulose and stir evenly, add 1ml acetylacetone, then add 1g urea, and finally slowly add 5ml tetrabutyl titanate, and finally the mixture is at room temperature Stir for 30min.

[0035] In the fourth step, ...

Embodiment 2

[0041] In the first step, the wet bacterial cellulose is rinsed with 2‰ hydrogen peroxide, then added to 2% sodium hydroxide alkali solution, heated and stirred at 100°C for 12 hours, then neutralized with acetic acid solution, and then washed with deionized water until neutralized. sex;

[0042] In the second step, the bacterial cellulose obtained in the first step is soaked in a solution with an ethanol volume concentration of 50%, and then gradually increases the proportion of ethanol in the solution to 90%, and removes the bacteria on the surface of the bacterial cellulose through solvent exchange. Sequenced water, and finally centrifuged to separate the bacterial cellulose.

[0043] In the third step, use 95% ethanol solution as a solvent, add the centrifuged bacterial cellulose and stir evenly. Add 1ml of acetylacetone, then add 5ml of ammonia solution with a mass fraction of 28%, and finally add 8ml of tetrabutyl titanate slowly, and finally the mixture is stirred at r...

Embodiment 3

[0047] The first step is to rinse the wet crude bacterial cellulose with 5‰ hydrogen peroxide, add it to 1% sodium hydroxide alkali solution, heat and stir at 100°C for 12 hours, then neutralize it with acetic acid solution, and then wash it with deionized water until neutralized. sex;

[0048] In the second step, the bacterial cellulose obtained in the first step is soaked in a solution with an ethanol volume concentration of 50%, and then gradually increases the proportion of ethanol in the solution to 90%, and removes the bacteria on the surface of the bacterial cellulose through solvent exchange. Sequenced water, and finally centrifuged to separate the bacterial cellulose.

[0049] In the third step, 90% ethanol solution was used as a solvent, and the centrifuged bacterial cellulose was added and stirred evenly. Add 2ml of acetylacetone, then add 1.2g of urea, and finally slowly add 10ml of tetrabutyl titanate, and finally the mixture is stirred at room temperature for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com