Wave absorbing composite nano-fiber material textile composition and its preparation process

A composite fiber and nano-textile technology, applied in the manufacture of conductive/antistatic filaments, etc., can solve the problems of shielding performance of electromagnetic wave shielding materials, restricted promotion prospects, low absorption rate, secondary pollution, etc., and can shorten the production process and scope. Wide, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

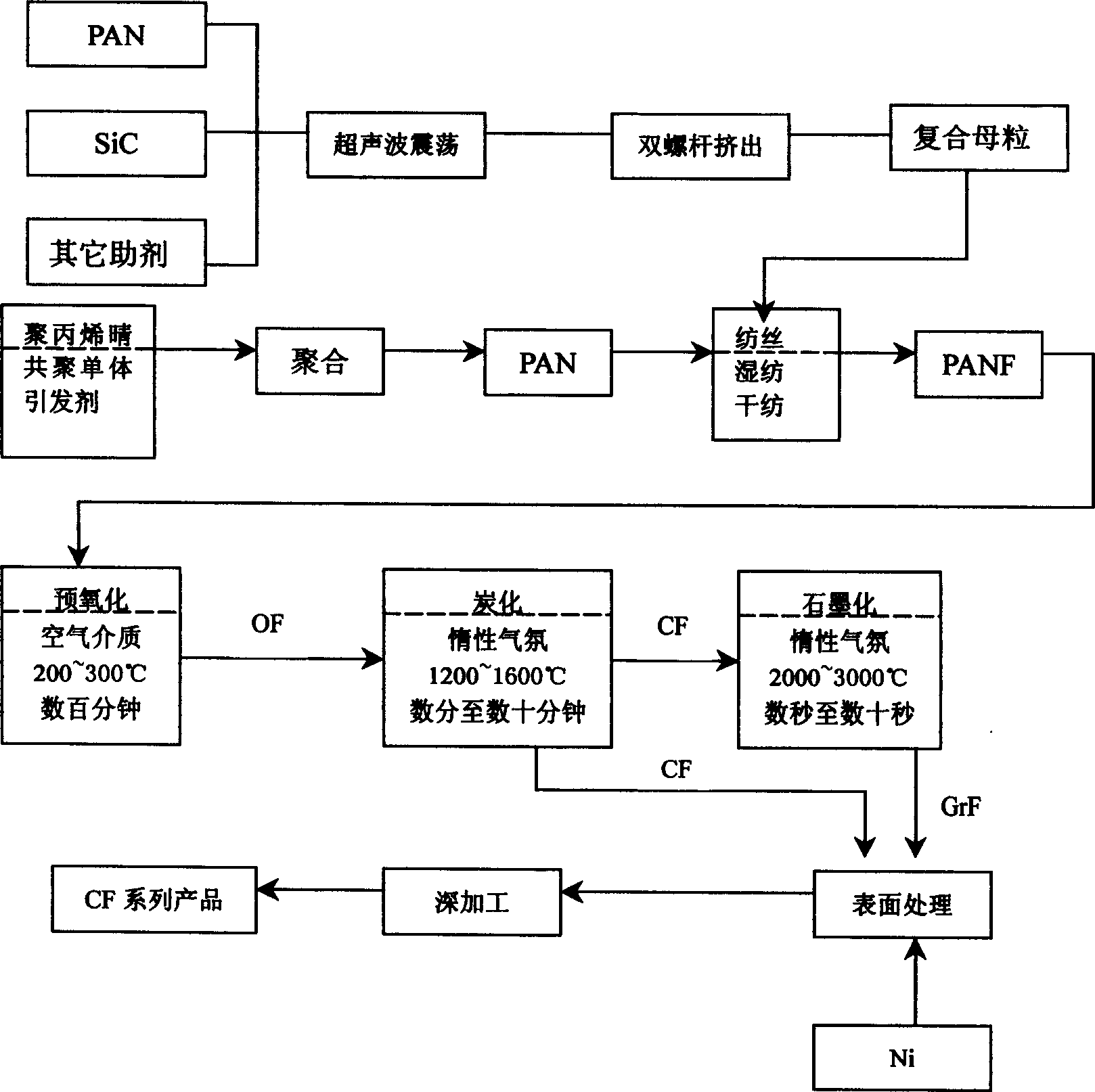

Method used

Image

Examples

Embodiment 1

[0053] The composition of the present invention contains polyacrylonitrile carbon 80~96% by weight, nanometer beta-silicon carbide 4~20%; Nickel powder consumption is 1~20% of fiber weight, auxiliary agent 5~8%, auxiliary agent is For methyl formamide, the pre-oxidation time is 220-240 minutes, the oxidation temperature is 240°C-280°C, the carbonization temperature is 1300°C-1400°C, the carbonization time is 9 minutes-10 minutes, and the inert atmosphere treatment temperature is 2500°C-2800°C °C, the time is 6 seconds to 8 seconds.

Embodiment 2

[0055] According to the weight ratio, the composition contains 85-94% of polyacrylonitrile carbon, 8-17% of nanometer β-silicon carbide; the amount of nickel powder is 5-15% of the fiber weight, 6-8% of auxiliary agent, and the auxiliary agent is methyl For formamide, the pre-oxidation time is 220-240 minutes, the oxidation temperature is 260°C-270°C, the carbonization temperature is 1300°C-1350°C, the carbonization time is 9 minutes-10 minutes, and the inert atmosphere treatment temperature is 2600°C-2700°C. The time is 6 seconds to 8 seconds.

Embodiment 3

[0057] According to the weight ratio, the composition contains 89-92% of polyacrylonitrile carbon, 10-14% of nano-beta silicon carbide; the amount of nickel powder is 2-10% of the fiber weight, and the auxiliary agent is 7-8%, and the auxiliary agent is methyl For formamide, the pre-oxidation time is 220-230 minutes, the oxidation temperature is 250°C-2650°C, the carbonization temperature is 1300°C-1360°C, the carbonization time is 7-8 minutes, and the inert atmosphere treatment temperature is 2550°C-2650°C. 6 to 7 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com