Terylene DTY fiber soft cotton velvet and technique for producing the same

A fiber and polyester technology, applied in the field of polyester DTY fiber loose wool blanket and its production process, can solve the problems of solid blanket, insufficient thickness, long dyeing and printing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to facilitate a further understanding of the present invention and make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the examples.

[0052] Case 1

[0053] A. Factors of production:

[0054] Product Name: Pine Cotton Velvet; Color: Pink; Gray Fabric Raw Material: Customized 200D / 288F Long Staple Silk + 100D / 36F Inserted Weft Yarn + 75D / 24F Braided Chain Yarn; Weaving Machine: GE288; Gray Fabric: Double Basic Fabric; Dyes : Dispersion; door width and weight: 205CM*240-250g / m 2 .

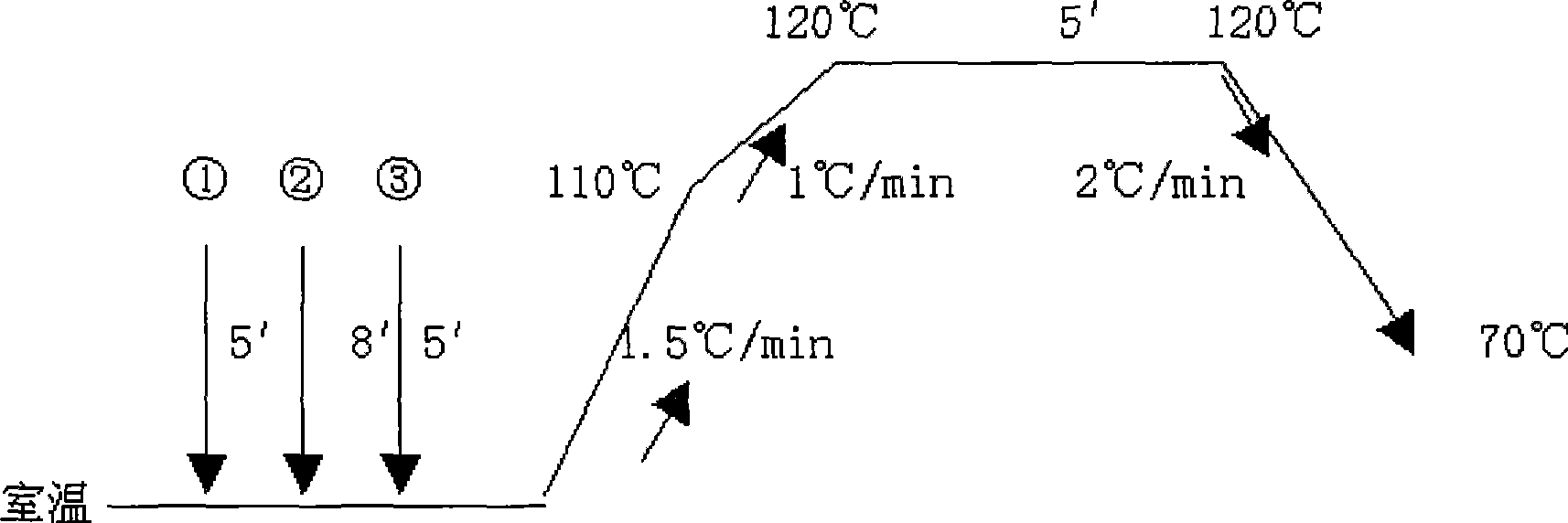

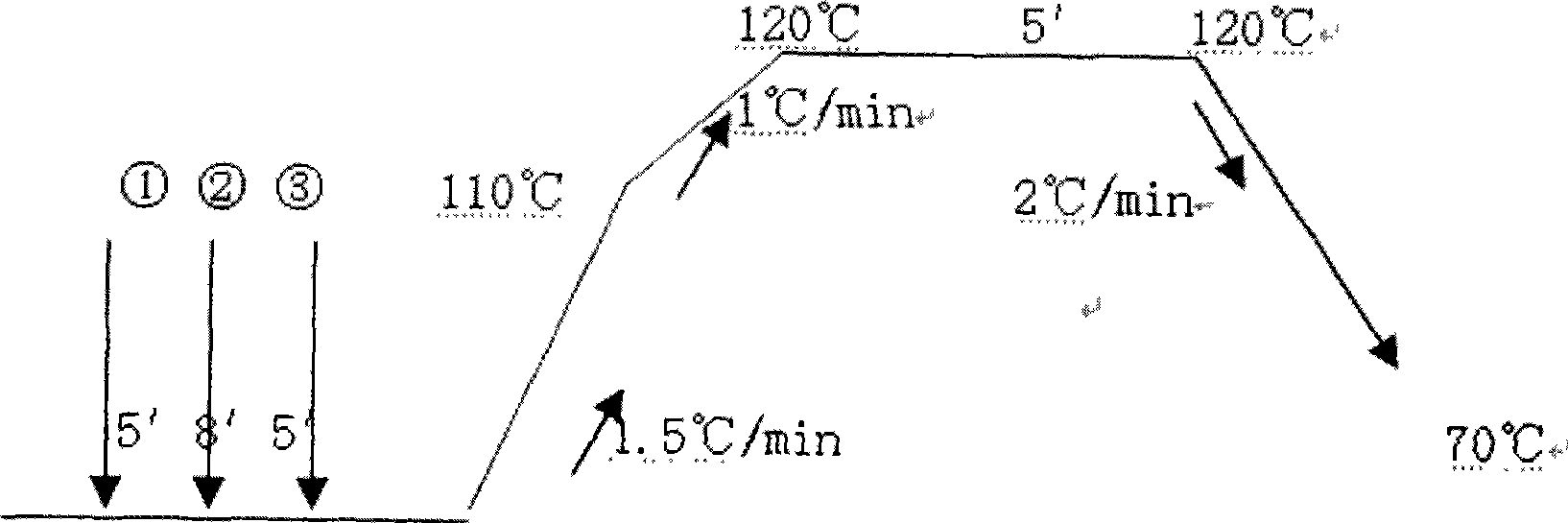

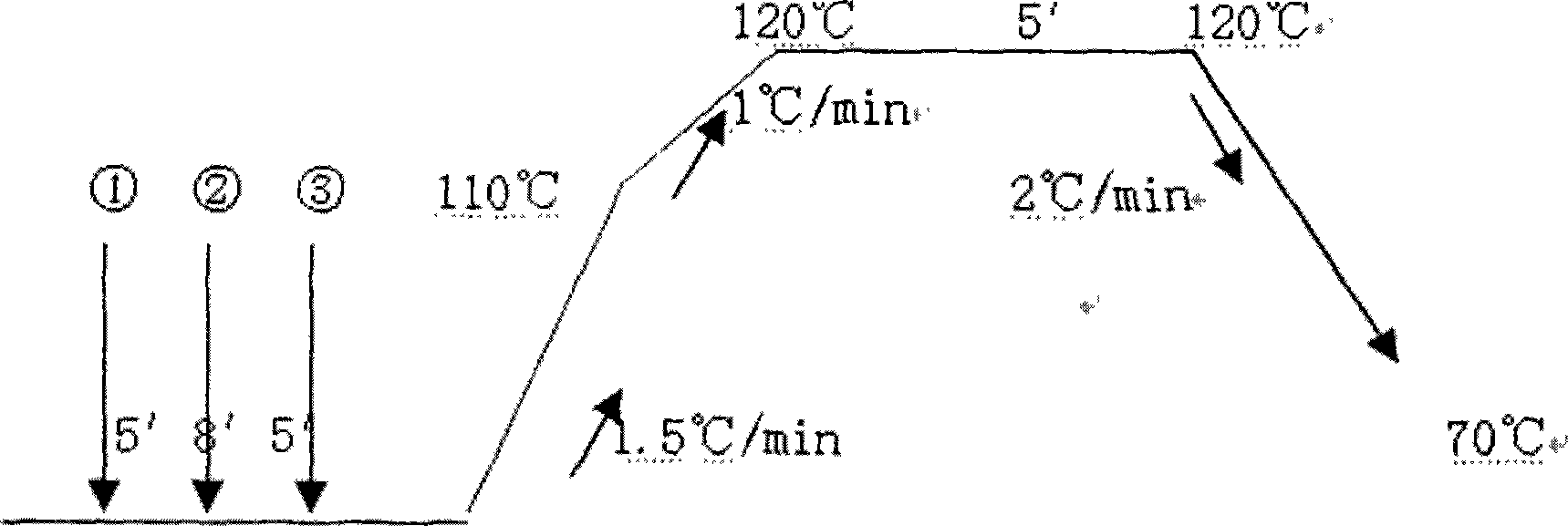

[0055] B. Process flow:

[0056] Customized raw materials - weaving blank - cutting width - blank inspection - cylinder division - carding - dyeing - rolling - dehydration - drying - napping (flat surface) - combing - ironing - ring drying - forming - inspection - packaging .

[0057] C. Combing parameters:

[0058] a. Combing: large cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com