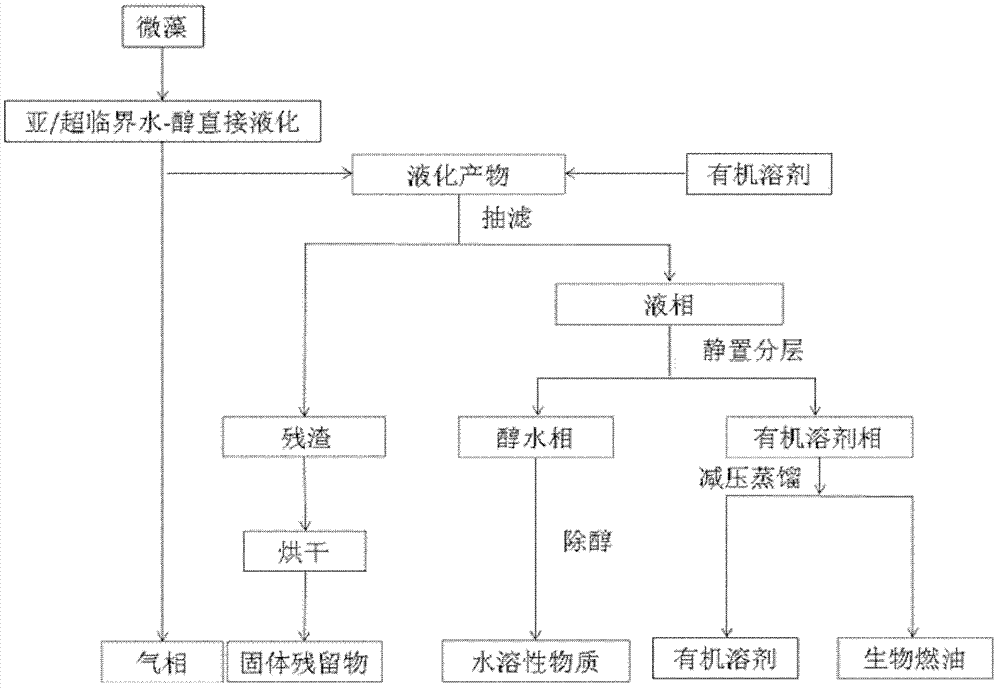

Method for preparing bio-oil from microalgae through direct liquidation

A biofuel and microalgae technology, applied in liquid carbon-containing fuel, fuel, petroleum industry and other directions, can solve the problems of unsatisfactory product biofuel quality, difficult recycling of catalysts, unsatisfactory bio-oil quality, etc., and achieve unique performance, The effect of high difference rate and low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to the solid-liquid ratio of 1:10 (g / mL), take by weighing 4g microalgae sample and 40mL water-alcohol mixture and join in the reaction kettle, the volume percentage of alcohol in the water-alcohol mixture medium is 40%, and the liquefaction temperature is 260°C; pressure 8.45MPa; reaction time 30min, the liquefaction rate of the obtained microalgae is 92.84%, and the oil production rate is 47.11%.

Embodiment 2

[0034] According to the solid-liquid ratio of 1:10 (g / mL), take by weighing 4g microalgae sample and 40mL water-alcohol mixture and join in the reaction kettle, the volume percentage of alcohol in the water-alcohol mixture medium is 40%, and the liquefaction temperature is 340°C; pressure 14.52MPa; reaction time 30min, the liquefaction rate of the obtained microalgae is 99.35%, and the oil production rate is 60.56%.

Embodiment 3

[0036] According to the solid-liquid ratio of 1:10 (g / mL), take 4g of microalgae samples and 40mL of water-alcohol mixture and add them to the reaction kettle. The volume percentage of alcohol in the water-alcohol mixture medium is 0%, and the liquefaction temperature is 320°C; pressure 11.27MPa; reaction time 30min, the liquefaction rate of the obtained microalgae is 95.39%, and the oil production rate is 48.93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com