Preparation method of mesoporous-containing Y-shaped molecular sieve

A molecular sieve and mesoporous technology, applied in octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of small pore size and pore volume of Y-type molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

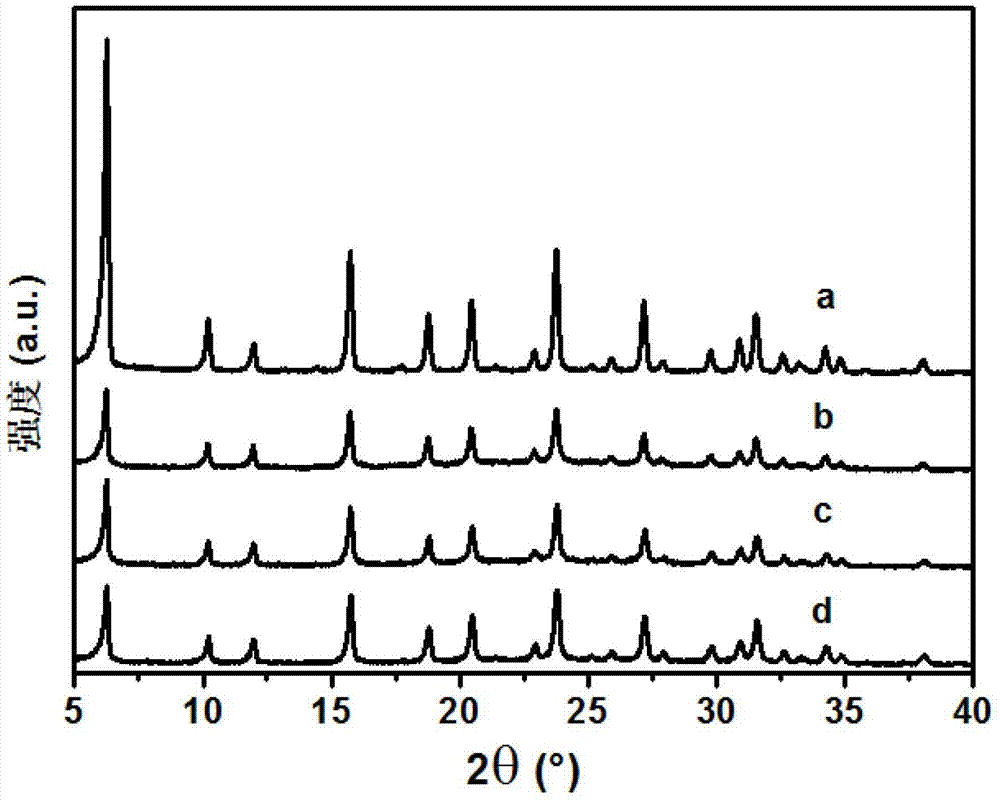

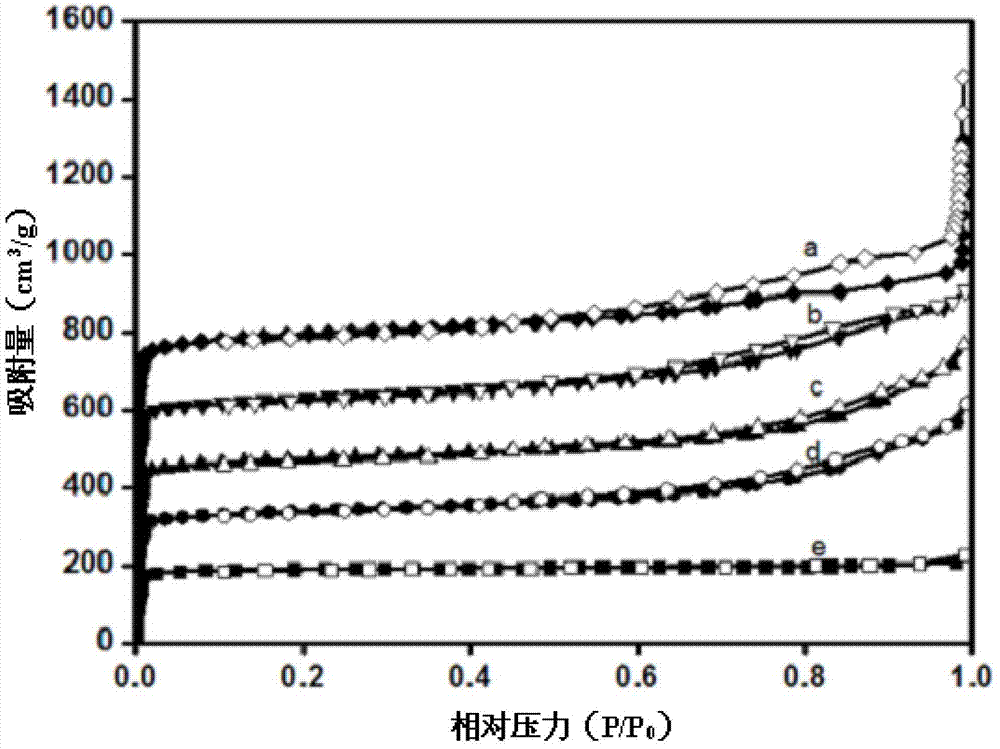

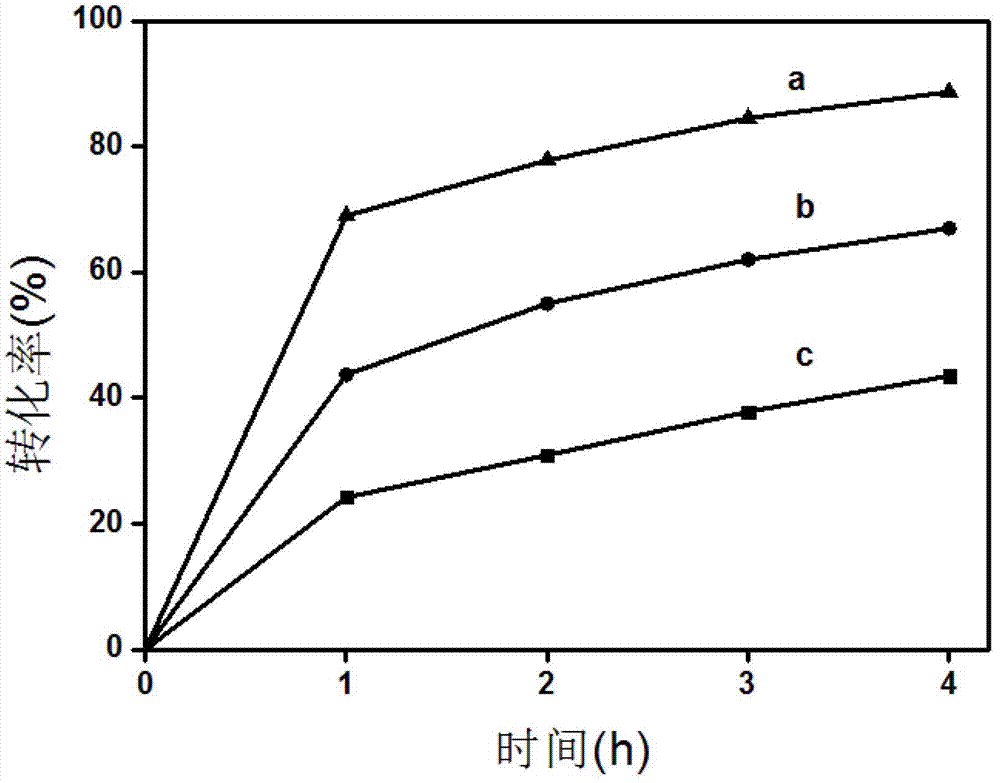

[0032] Specific embodiment one: the preparation method of a kind of Y-type molecular sieve containing mesoporous in this embodiment, carries out according to the following steps:

[0033] 1. Preparation of sodium-type Y-type molecular sieve: Add aluminum source and NaOH to deionized water, heat at a temperature of 30°C to 50°C until completely dissolved to obtain a mixed solution, and then stir at a stirring speed of 400rpm to 600rpm Add the mixed solution to the silicon source, mix and stir evenly, age at room temperature for 1 to 2 days, then crystallize at a temperature of 20°C to 120°C for 1 to 4 days, filter to obtain a white solid, and finally Dry the white solid obtained at a temperature of 40°C to 120°C for 5h to 12h to obtain a sodium Y-type molecular sieve; wherein the molar ratio of NaOH to aluminum source is (4-8):1, and the The molar ratio of deionized water and aluminum source is (160~320):1, the molar ratio of described silicon source and aluminum source is (1.2...

specific Embodiment approach 2

[0042] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the quality and concentration of the sodium Y-type molecular sieve prepared in step 1 described in step 2 is an organic acid aqueous solution with a concentration of 0.01 mol / L to 0.5 mol / L The volume ratio is 1g:15mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the quality of the Na-DA molecular sieve prepared in step two described in step three and the NaOH solution whose concentration is 0.1mol / L~2mol / L The volume ratio is 1g:30mL. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore volume | aaaaa | aaaaa |

| Average mesopore diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com