Method for preparing vanadium-silicon molecular sieve

A silicon molecular sieve, vanadium source technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolite and other directions, can solve the problems of high product cost, affect product activity, complex preparation process, etc., achieve good desulfurization effect, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] With 10.6g silica gel (Lanzhou Catalyst Factory, burning loss 3% by weight, alumina content 1% by weight), 1.36g vanadyl sulfate, 1.33gNaOH and 36gH 2 O mixed, then added 2.46g n-butylamine, stirred evenly, the molar composition of the resulting reaction mixture was: SiO 2 : 0.05VO 2 : 0.2CH 3 (CH 2 ) 3 NH 2 :0.2NaOH:12H 2 O. Put this reaction mixture into a closed crystallization tank for crystallization at 120°C for 1 day, then at 150°C for 1 day, filter, wash, and dry at 120°C to obtain sample Z1.

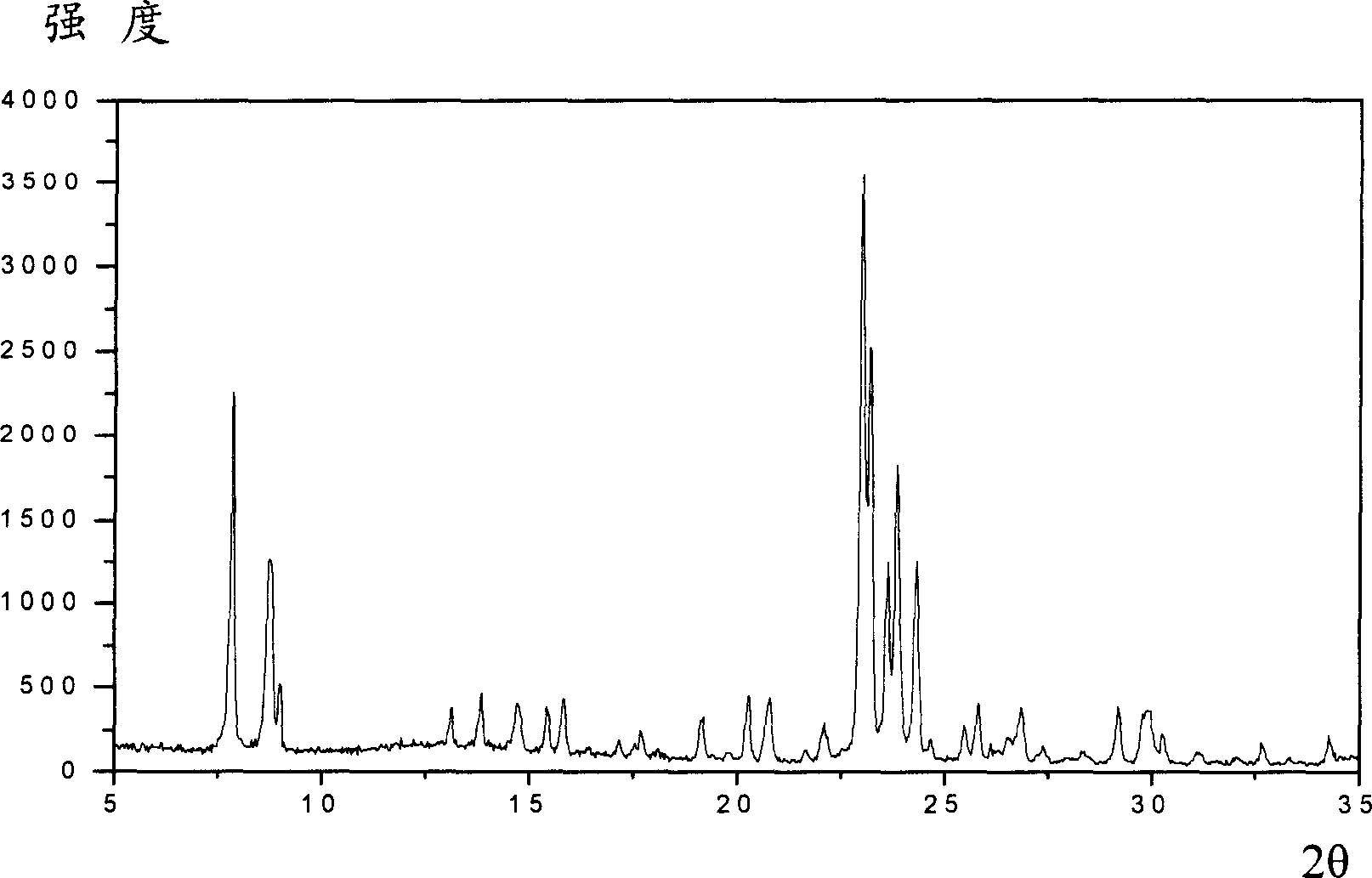

[0040] The XRD spectrum of Z1 is shown in figure 1 , showing that Z1 has a typical MFI structure, and its relative crystallinity is 91.2% (relative to Silicate-1 with good crystallinity, the same below, Silicate-1 is according to Stud.Surf.Sci.Catal., 18, (1984) P159 synthesized by the method described above).

[0041] NH for Z1 4 After Cl was exchanged several times, the molar composition of its anhydrous oxide was analyzed by fluorescence: 0.024V 2 o 5 : SiO...

Embodiment 2

[0045] 15.9g silica gel, 6.12g vanadyl sulfate, 4gNaOH and 54gH 2 O mixed, then added 4.94g n-butylamine, stirred evenly, the molar composition of the resulting reaction mixture was: SiO 2 : 0.15VO 2 : 0.25CH 3 (CH 2 ) 3 NH 2 :0.4NaOH:12H 2 O. The reaction mixture was crystallized at 150° C. for 4 days, filtered, washed, and dried at 120° C. for two hours to obtain sample Z2.

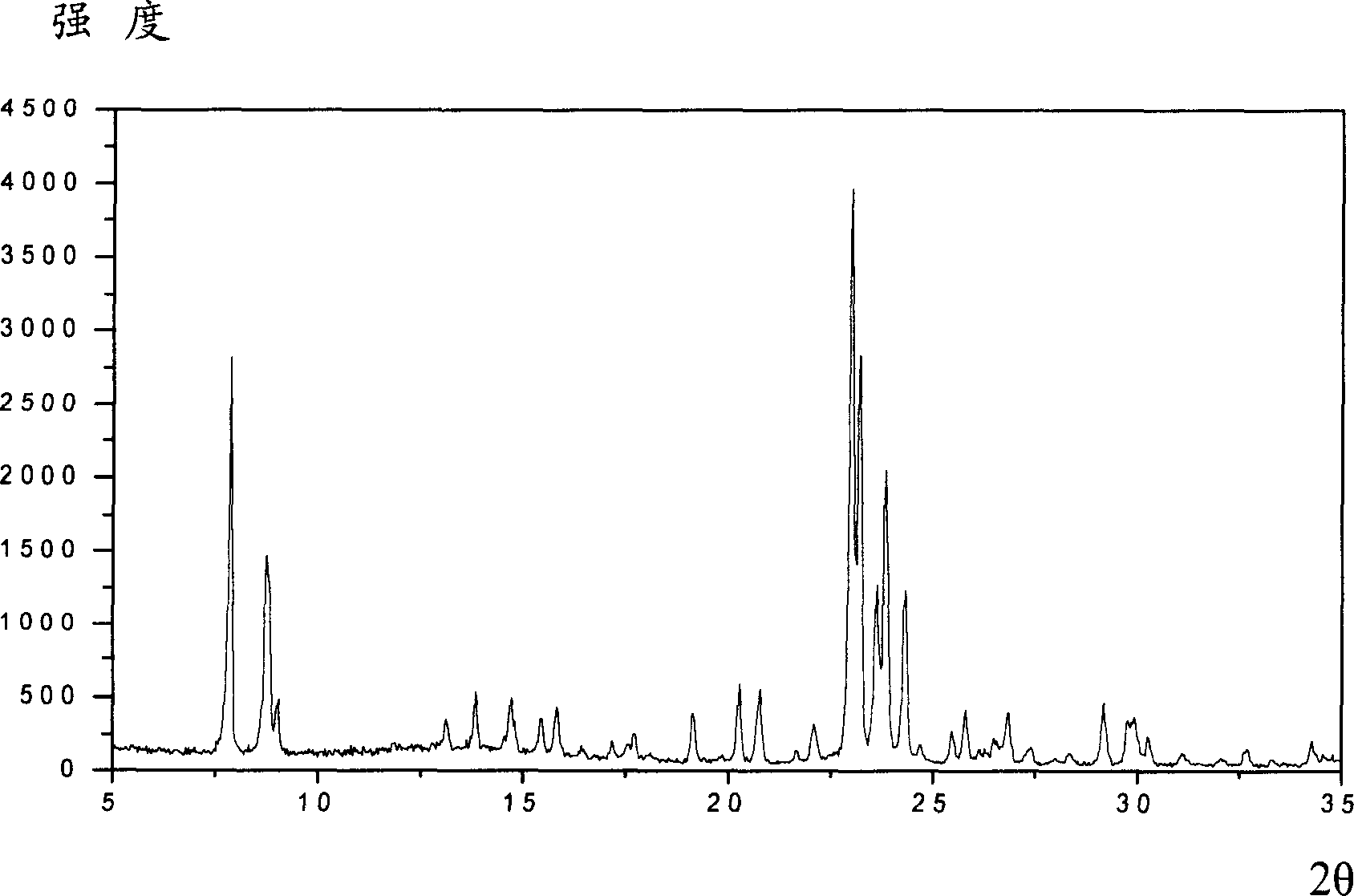

[0046] The XRD spectrum of Z2 is shown in figure 2 , indicating that Z2 has a typical MFI structure with a relative crystallinity of 83%.

[0047] NH for Z2 4 After Cl was exchanged several times, the molar composition of its anhydrous oxide was analyzed by fluorescence: 0.07V 2 o 5 : SiO 2 : 0.008Al 2 o 3 .

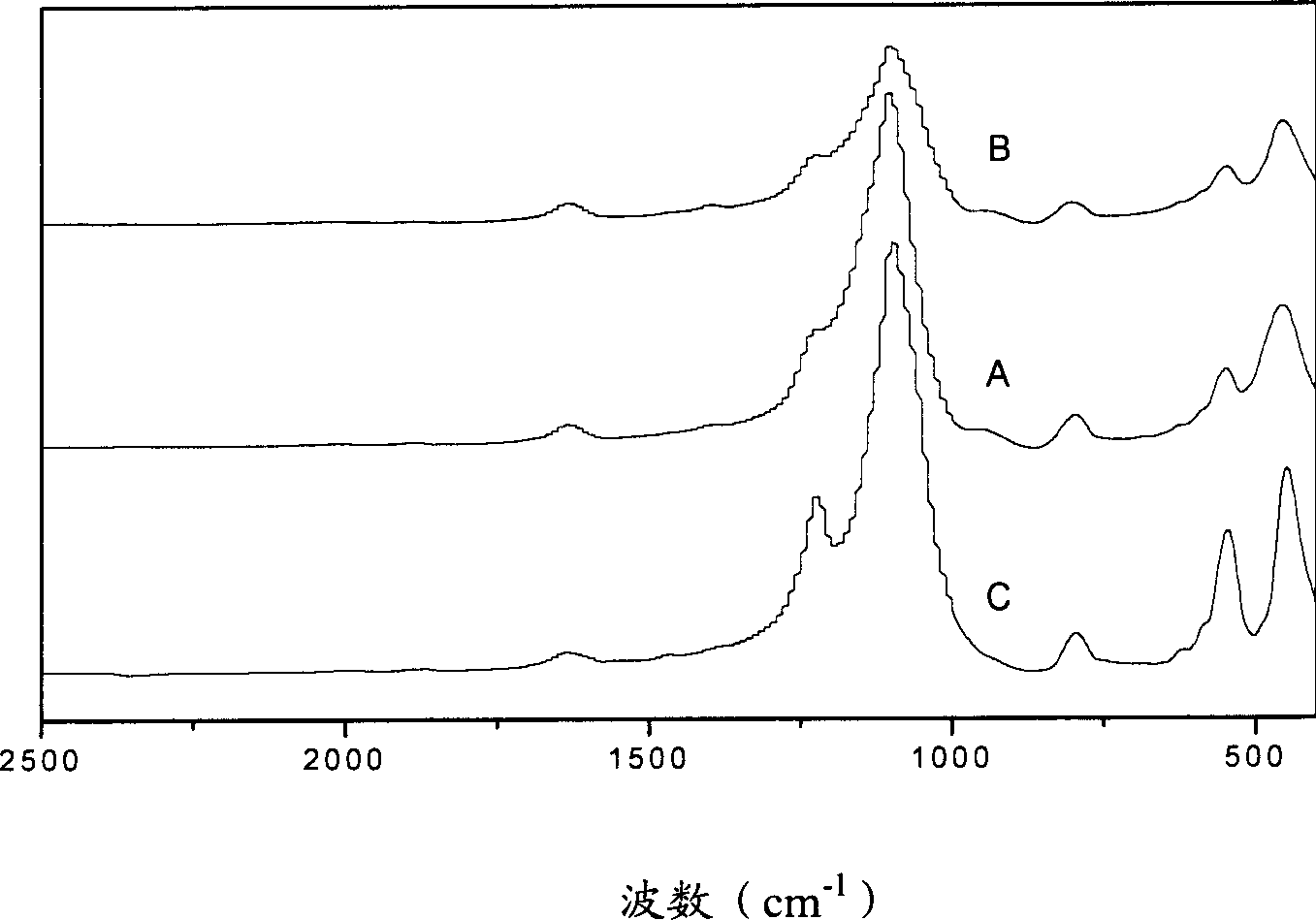

[0048] IR skeleton analysis spectrum see image 3 The B curve also appears 970cm -1 The characteristic absorption peak of , indicating that V enters the molecular sieve framework.

[0049] 51 V MAS NMR spectrum see Figure 4 The resonance peak of the chemical shift -868.5ppm f...

Embodiment 3

[0051] With the method and step of embodiment 1, the difference is that V 2 o 5 and the amount of NaOH, the molar composition of the prepared reaction mixture: SiO 2 : 0.02VO 2 : 0.2CH 3 (CH 2 ) 3 NH 2 : 0.1NaOH: 12H 2 O.

[0052] The above reaction mixture was crystallized at 150°C for 5 days, and the crystallized product was filtered, washed, and dried to obtain sample Z3, whose XRD pattern had figure 1 characteristics, the relative crystallinity is 94.7%.

[0053] use NH 4 After Cl was exchanged several times, the molar composition of its anhydrous oxide was analyzed by fluorescence to be 0.009V 2 o 5 : SiO 2 : 0.01Al 2 o 3 .

[0054] The IR spectrum of sample Z3 has image 3 A characteristic of the curve, 51 The V MAS NMR spectrum has Figure 4 A characteristic of the curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com