Method for preparing carbon nanofiber aerogel from wood

A carbon nanofiber and nanocellulose technology, applied in the field of nanomaterials, can solve the problems of toxic tellurium nanowires, unsuitable for commercialization, complex and expensive chemical vapor deposition, etc., and achieve simple and easy preparation methods, easy large-scale preparation, Realize the effect of large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

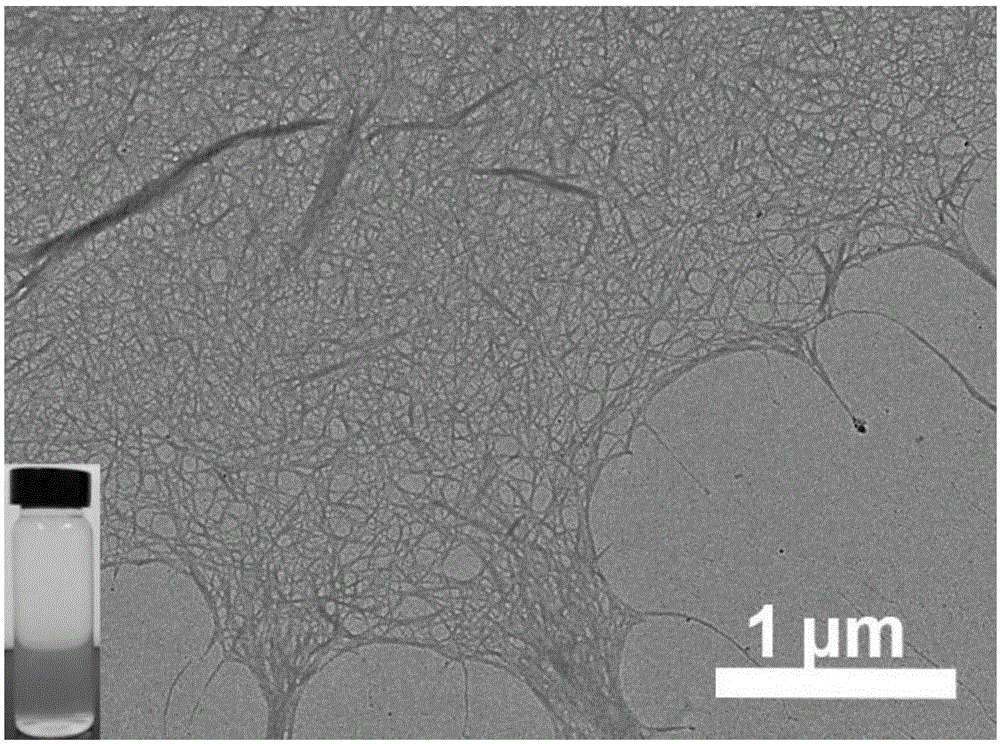

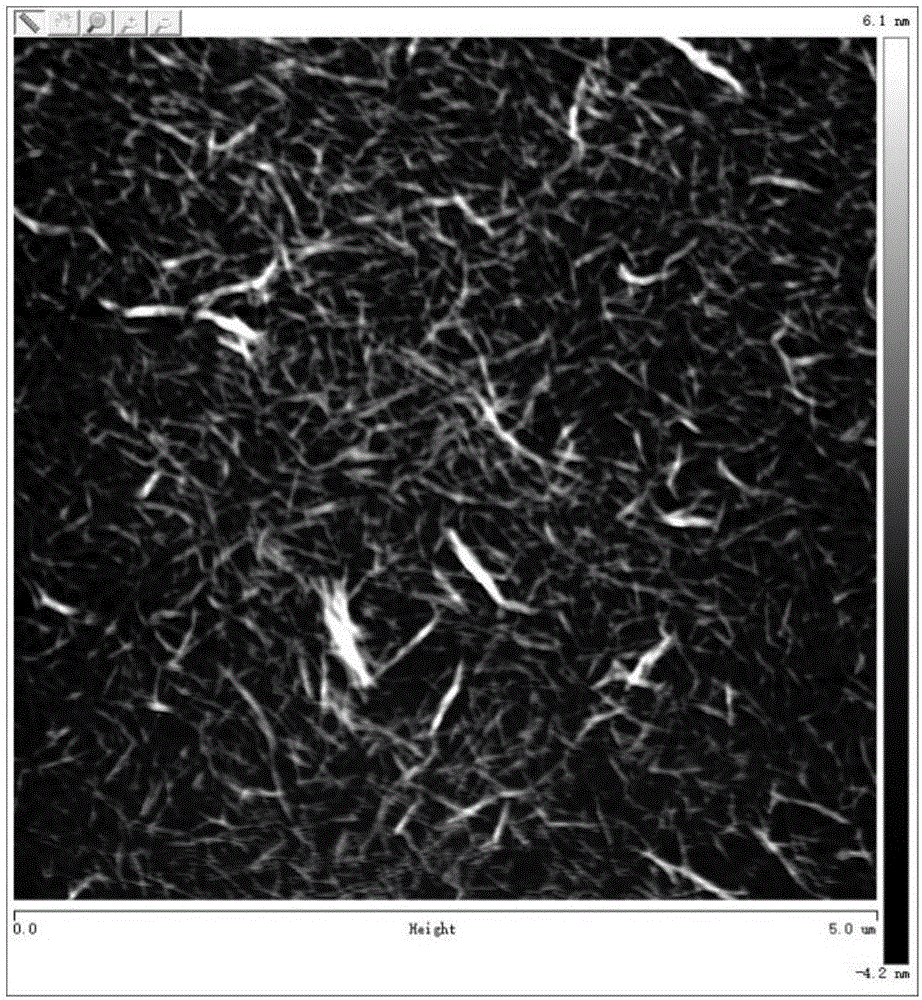

[0051] Disperse 3.75g of bleached wood pulp (solid content 26.67%) into 100mL of water, stir well, then add 0.016g, 0.1mmol tetramethylpiperidine oxide and 0.1g, 1mmol sodium bromide, use 1M hydrochloric acid Adjust 10ml of 9% sodium hypochlorite solution to a pH of 10, add the sodium hypochlorite solution with a pH of 10 into the dispersion, keep stirring, use a pH meter to detect the pH change of the solution, and add 1M sodium hydroxide dropwise during the reaction to keep the pH of the solution After reacting for 4 to 10 hours, filter with suction, wash with deionized water several times, and disperse the white viscous substance after suction filtration in 100ml of water. The obtained dispersion liquid was mechanically processed in a mixer at a speed of about 37000 / min, and after stirring, it was ultrasonically treated in a cell disruptor to obtain a nanocellulose solution.

[0052] Add dropwise 1M hydrochloric acid to 20mL of 0.6wt% nanocellulose solution until the pH is ...

Embodiment 2

[0058] Disperse 3.75g of bleached wood pulp (solid content 26.67%) into 100mL of water, stir well, then add 0.016g, 0.1mmol tetramethylpiperidine oxide and 0.1g, 1mmol sodium bromide, use 1M hydrochloric acid Adjust 10ml of 9% sodium hypochlorite solution to a pH of 10, add the sodium hypochlorite solution with a pH of 10 into the dispersion, keep stirring, use a pH meter to detect the pH change of the solution, and add 1M sodium hydroxide dropwise during the reaction to keep the solution The pH is 10-10.3. After reacting for 4-10 hours, filter with suction, wash with deionized water several times, and disperse the white viscous substance after suction filtration in 100ml of water. The obtained dispersion liquid was mechanically processed in a mixer at a speed of about 37000 / min, and after stirring, it was ultrasonically treated in a cell disruptor to obtain a nanocellulose solution.

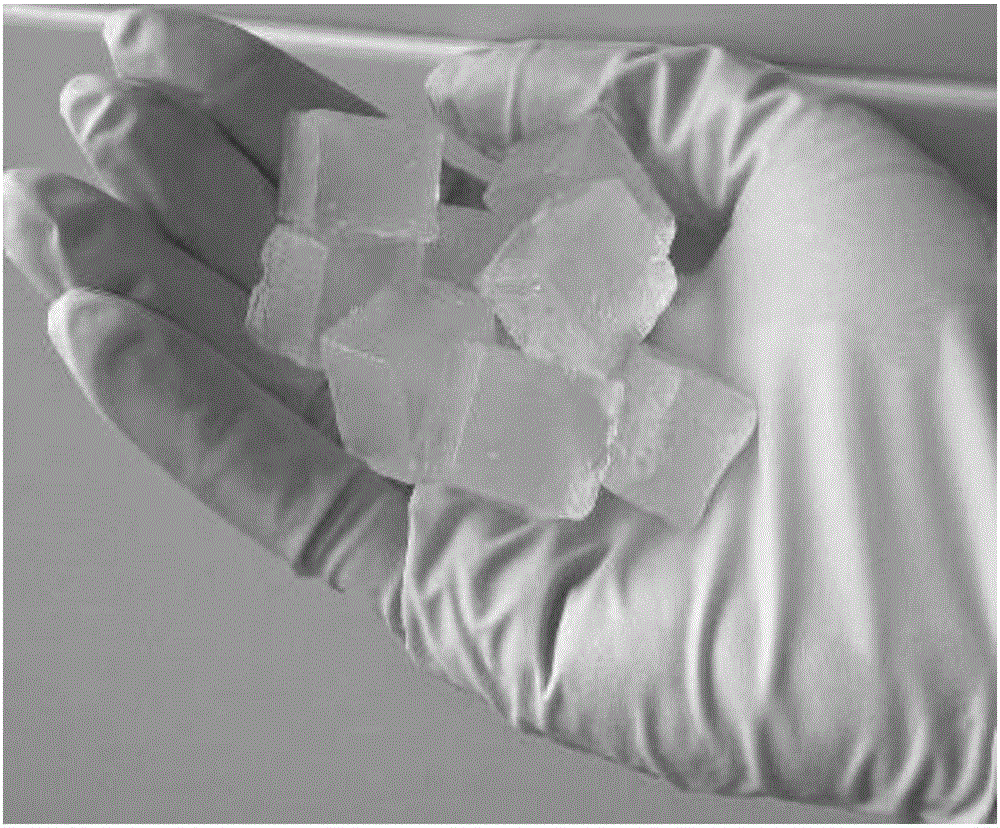

[0059] Take 10ml of the 0.4wt% nanocellulose solution to cover the bottom of a glass petri d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com