BiOBr0.2I0.8/graphene composite visible-light-induced photocatalyst and preparation method thereof

A graphene composite and visible light technology, which is applied in the field of photocatalysis, can solve the problems of bismuth oxyhalide solid solution/graphene composite visible light catalyst, and achieve high visible light catalytic activity, uniform particle size, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (a) Disperse 0.050 g of graphite oxide in 7 ml of dehydrated ethanol solution, and ultrasonicate for 2 h to obtain a suspension of graphene oxide;

[0028] (b) At room temperature, dissolve 0.0617 g of sodium bromide and 0.8224 g of potassium iodide in 4 ml of dehydrated ethylene glycol;

[0029] (c) 1.4552 g of bismuth nitrate is dissolved in 35 ml of ethylene glycol;

[0030] (d) Slowly add the solution obtained in step (b) dropwise to the solution obtained in step (c), and continue to stir for 1h;

[0031] (e) slowly adding the suspension obtained in step (a) dropwise to the solution obtained in step (d);

[0032] (f) After stirring the solution obtained in step (e) for 1 h, transfer it to a polytetrafluoroethylene-lined autoclave, and conduct a crystallization reaction at 160 °C for 12 h;

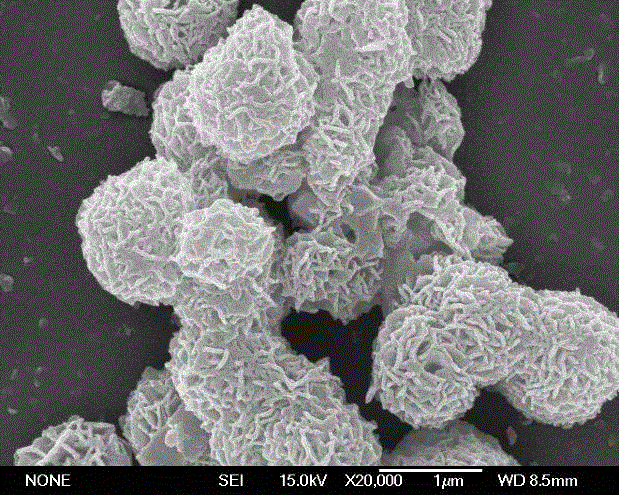

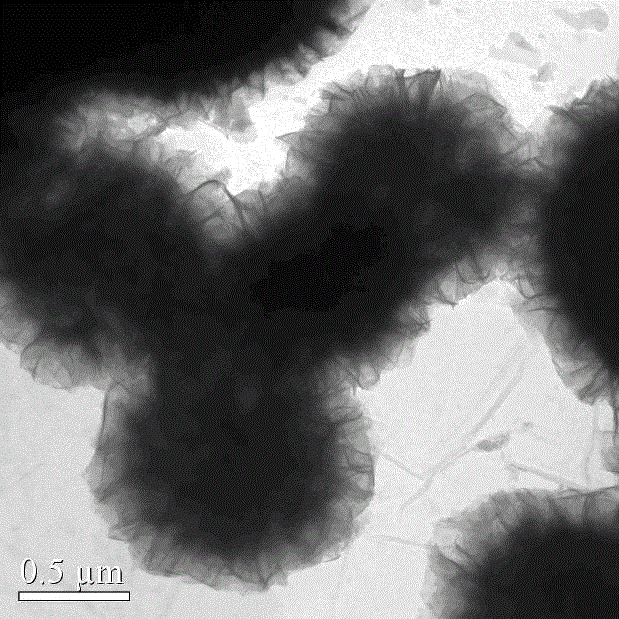

[0033] (g) The resulting solid product was filtered, washed, and dried at 100°C for 24 h to obtain 10.0% BiOBr with a mass percentage of graphene 0.2 I 0.8 / Graphene composit...

Embodiment 2

[0036] Operation process is except following difference, all the other are with embodiment 1.

[0037]Disperse 0.025 g of graphite oxide in 5 ml of ethanol and sonicate for 2 h. Finally, BiOBr with a graphene content of 5.0 wt.% was obtained 0.2 I 0.8 / Graphene composite visible light catalyst.

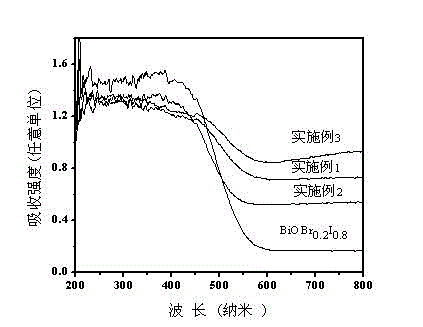

[0038] The XRD result of the sample can be found in figure 1 , the TEM result of the sample is similar to that of Example 1, and the ultraviolet-visible absorption spectrum is shown in Figure 4 , photocatalytic performance see Figure 5 .

Embodiment 3

[0040] Operation process is except following difference, all the other are with embodiment 1.

[0041] Disperse 0.075 g of graphite oxide in 9 ml of ethanol and ultrasonicate for 2 h. Finally, BiOBr with a graphene content of 15.0 wt.% was prepared 0.2 I 0.8 / Graphene composite visible light catalyst.

[0042] The XRD result of the sample can be found in figure 1 , the TEM result of the sample is similar to that of Example 1, and the ultraviolet-visible absorption spectrum is shown in Figure 4 , photocatalytic performance see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com