Nanometer bacteria cellulose aldehyde grouping modified method

A bacterial cellulose and nano-bacteria technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low performance of bacterial cellulose and cells, and achieve improved reactivity and cell adhesion, The effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

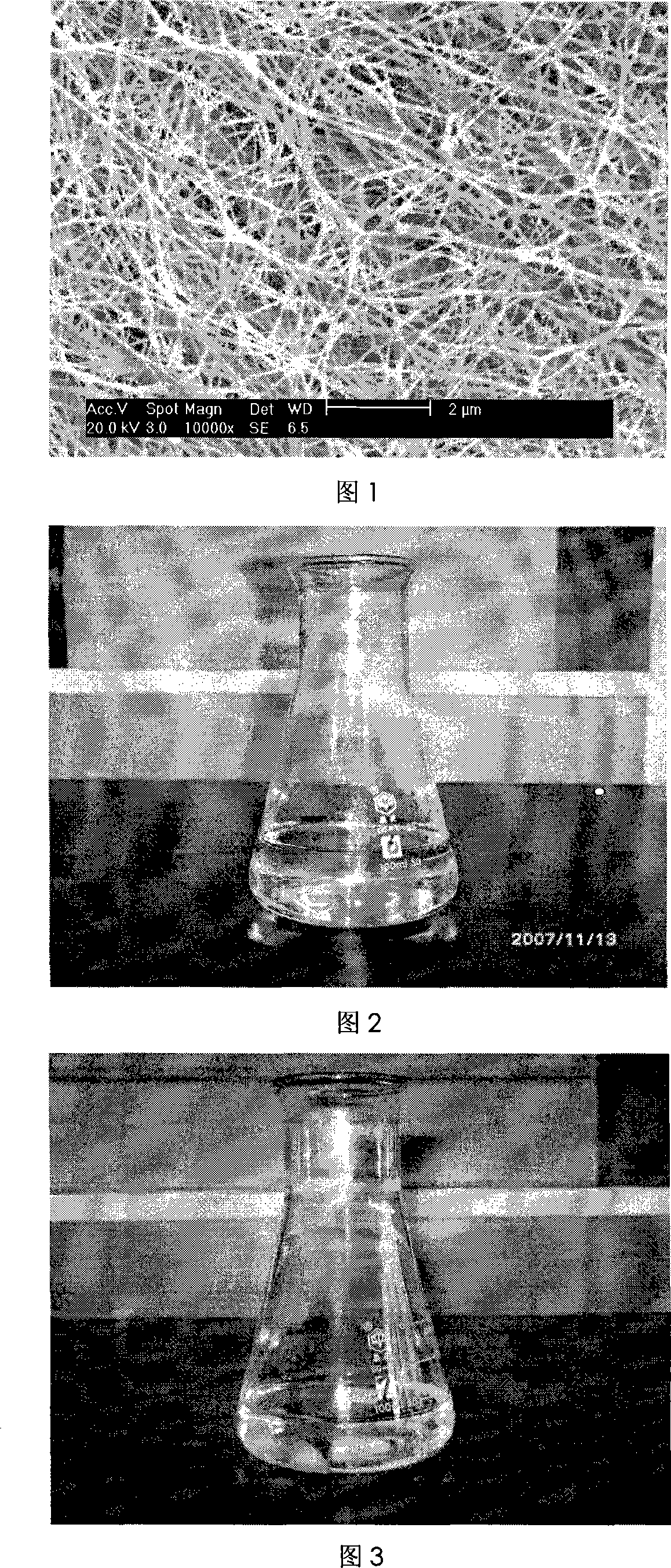

[0027] Using Acetobacter xylinum as a bioreactor, a milky white bacterial cellulose hydrogel film was prepared by fermentation [L.Hong, Y.L.Wang, S.R.Jia, Y.Huang, C.Gao, Y.Z.Wan Hydroxyapatite / bacterialcellulose composites synthesized via a biomimetic route, Materials Letters 60(2006) 1710-1713.]. The strains of Acetobacter xylinum were placed in agar solid medium and kept refrigerated at 4°C.

[0028] Suspend 50 g of bacterial cellulose produced by Acetobacter xylinum in deionized water, add 0.1 g of 2,2,6,6-tetramethylpiperidine oxide and 1.3 g of sodium bromide, and stir thoroughly. Then slowly add 0.25 g of sodium hypochlorite solution with 10% available chlorine, and add 0.5 M sodium hydroxide solution to adjust the pH of the system to 11. Start timing, and after reacting at 25° C. for 30 min, add 40 ml of absolute ethanol to terminate the reaction. After the bacterial cellulose is taken out and rinsed repeatedly with deionization, the aldylated bacterial cellulose is ...

example 2

[0036] Suspend 50 g of bacterial cellulose produced by Acetobacter xylinum in deionized water, add 0.1 g of 2,2,6,6-tetramethylpiperidine oxide and 1.3 g of sodium bromide, and stir thoroughly. Then slowly add 0.5 g of sodium hypochlorite solution with 5% available chlorine, and add 0.5 M sodium hydroxide solution to adjust the pH of the system to 10. Start timing, and after reacting at 30° C. for 20 minutes, add 40 ml of absolute ethanol to terminate the reaction. After the bacterial cellulose is taken out and rinsed repeatedly with deionization, the aldylated bacterial cellulose is obtained. The evaluation method is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com