Production method of insulating fireproof decorating plate

A production method and technology for decorative panels, applied in the field of building decorative materials, can solve the problems of difficult construction quality control, hidden dangers of engineering safety, low degree of industrialization, etc., and achieve the effects of luxurious decoration effect, reasonable stress structure and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

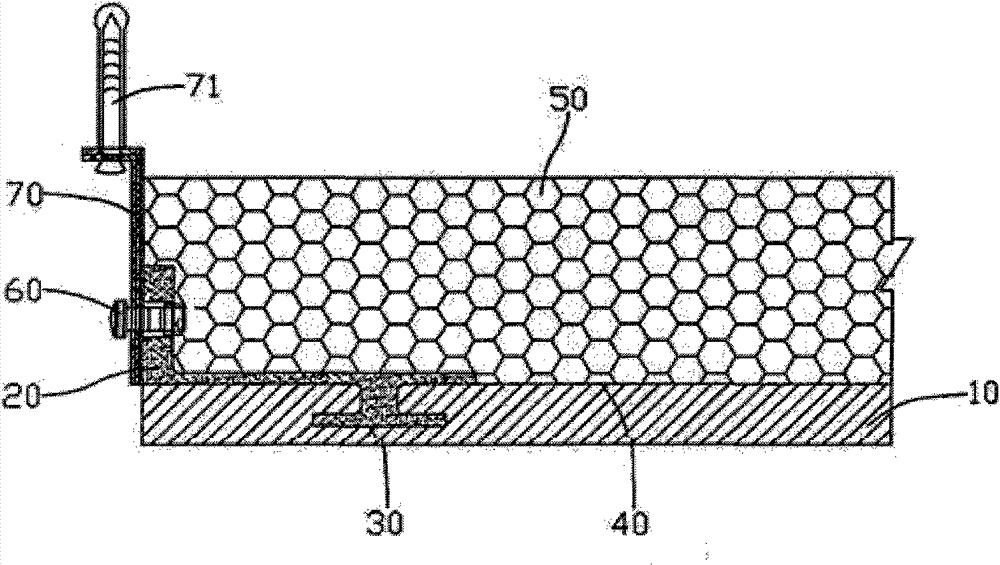

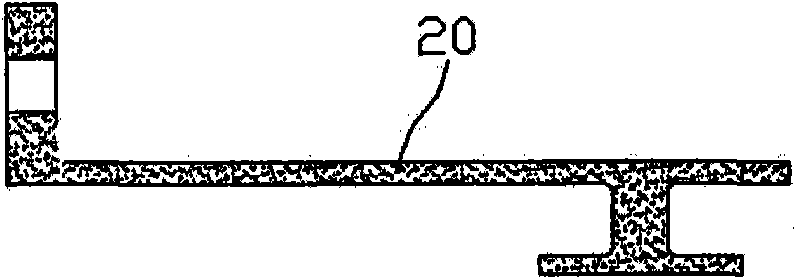

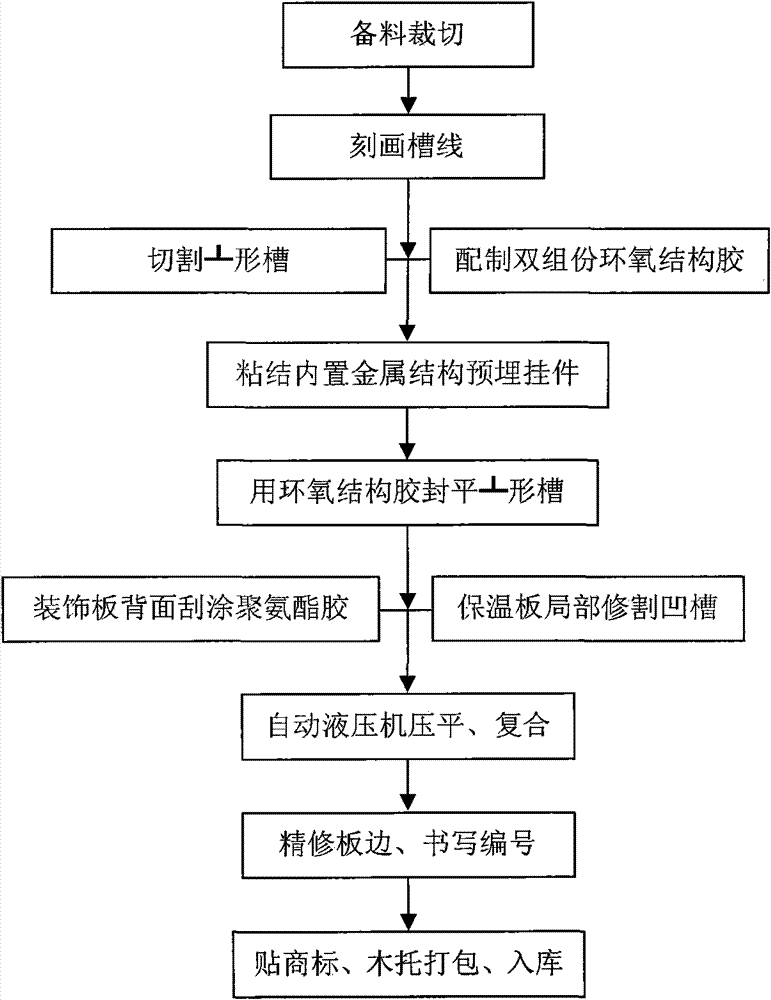

[0034] Example: use a piece of ultra-thin stone with a thickness of only 10mm, and its entire board width is 600×900mm, put it flat on the workbench with the back facing up, and draw 4 horizontally on the four corners from the upper side down and the lower side up to 40mm in the middle. A 80-120mm long groove line, along which the "⊥"-shaped groove hole 11 is cut twice; clean and dry the groove hole 11 in the fastest time, and at the same time prepare a two-component epoxy structural adhesive 30 and apply it on the metal The "I" character part of the structural embedded part 20 and the contact surface with the back surface of the plate 10 are then pushed horizontally from the outside to the inside of the 80-120mm slot 11. And use epoxy structural glue 30 to seal the gap of the flat "⊥" shaped slot 11, clean the dirt and water stains on the back of the board 10 again, scrape and apply polyurethane glue 40 evenly, and pre-embed the insulation board 50 in close contact with the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com