Patents

Literature

89results about How to "Improve charging characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

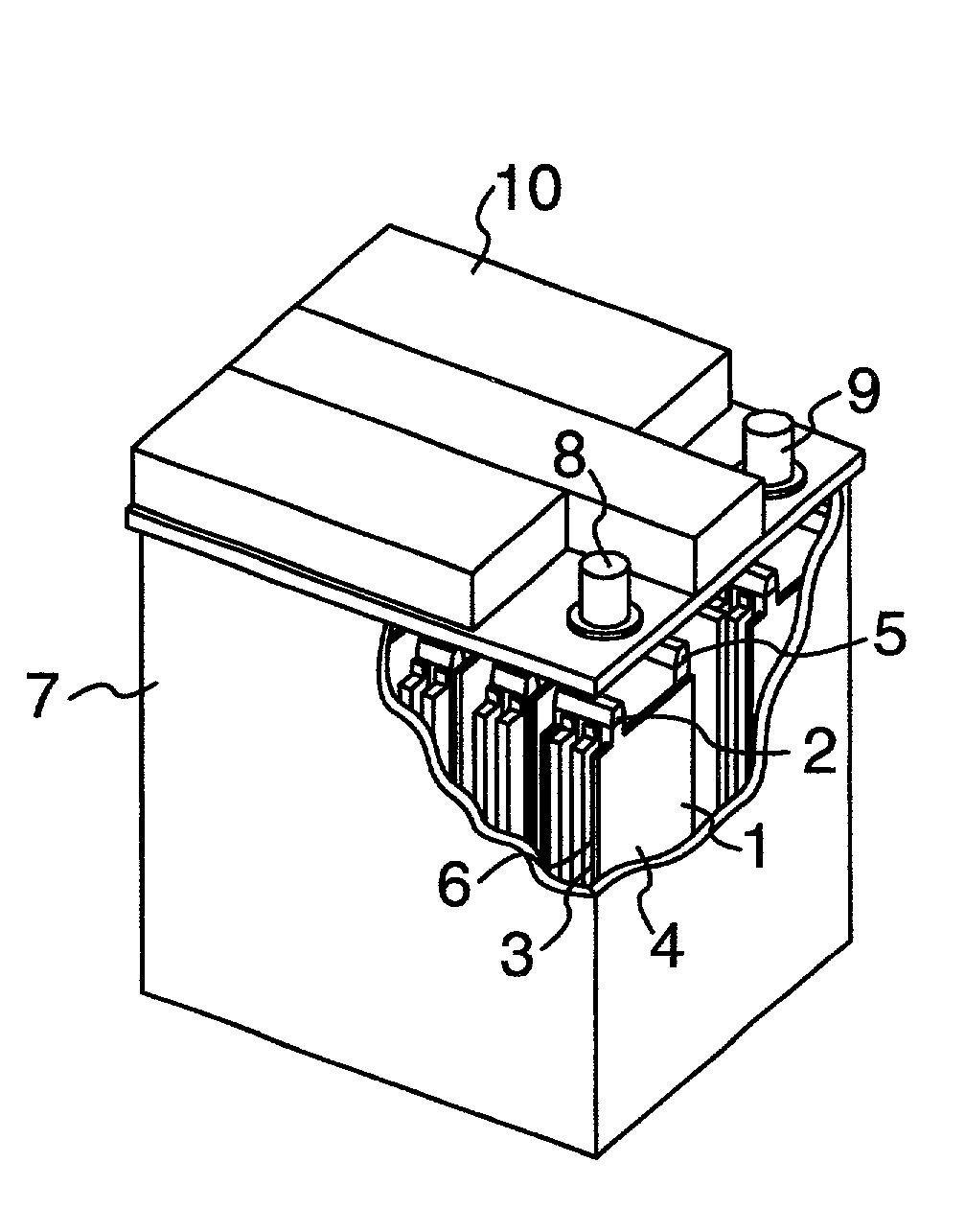

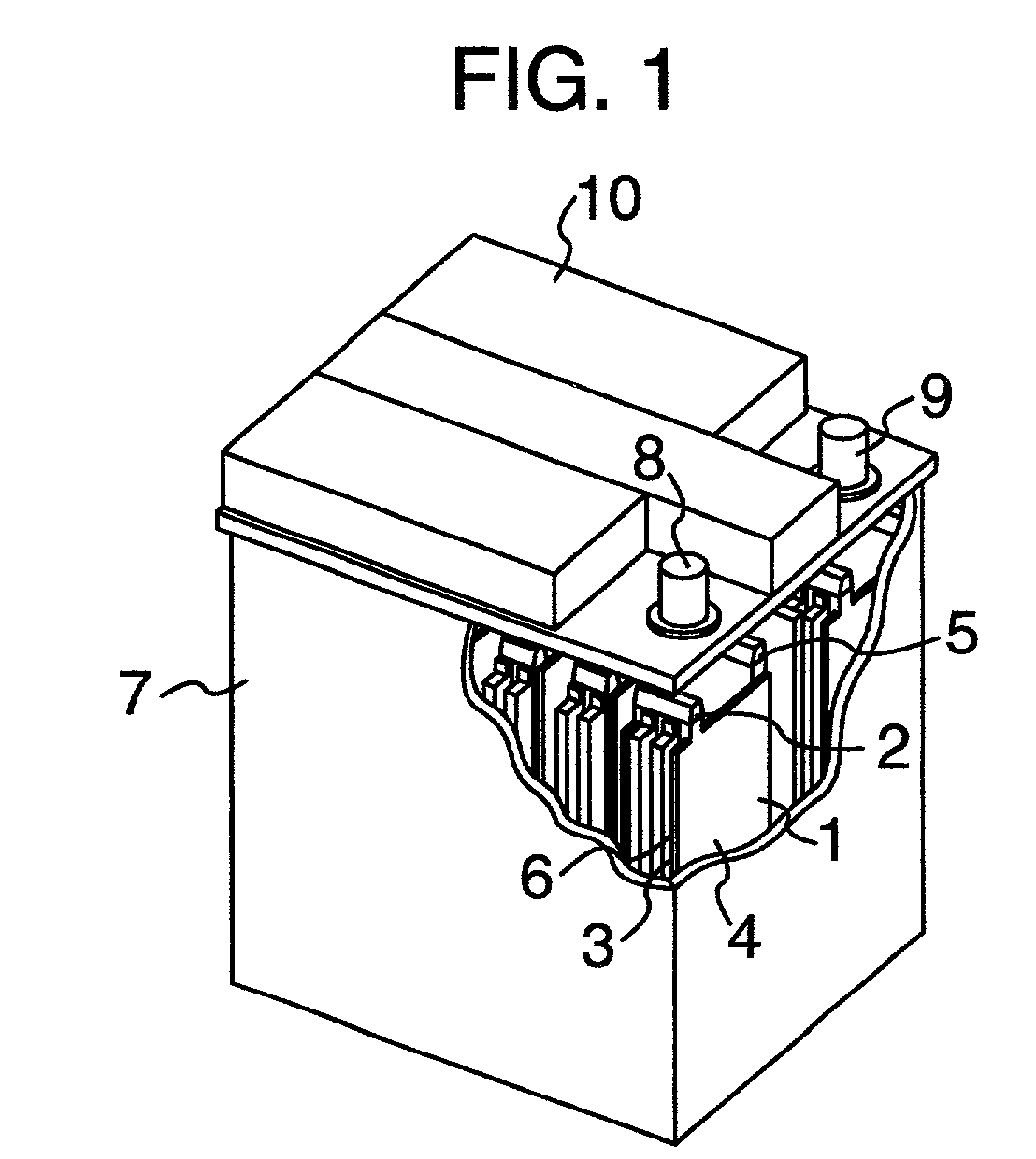

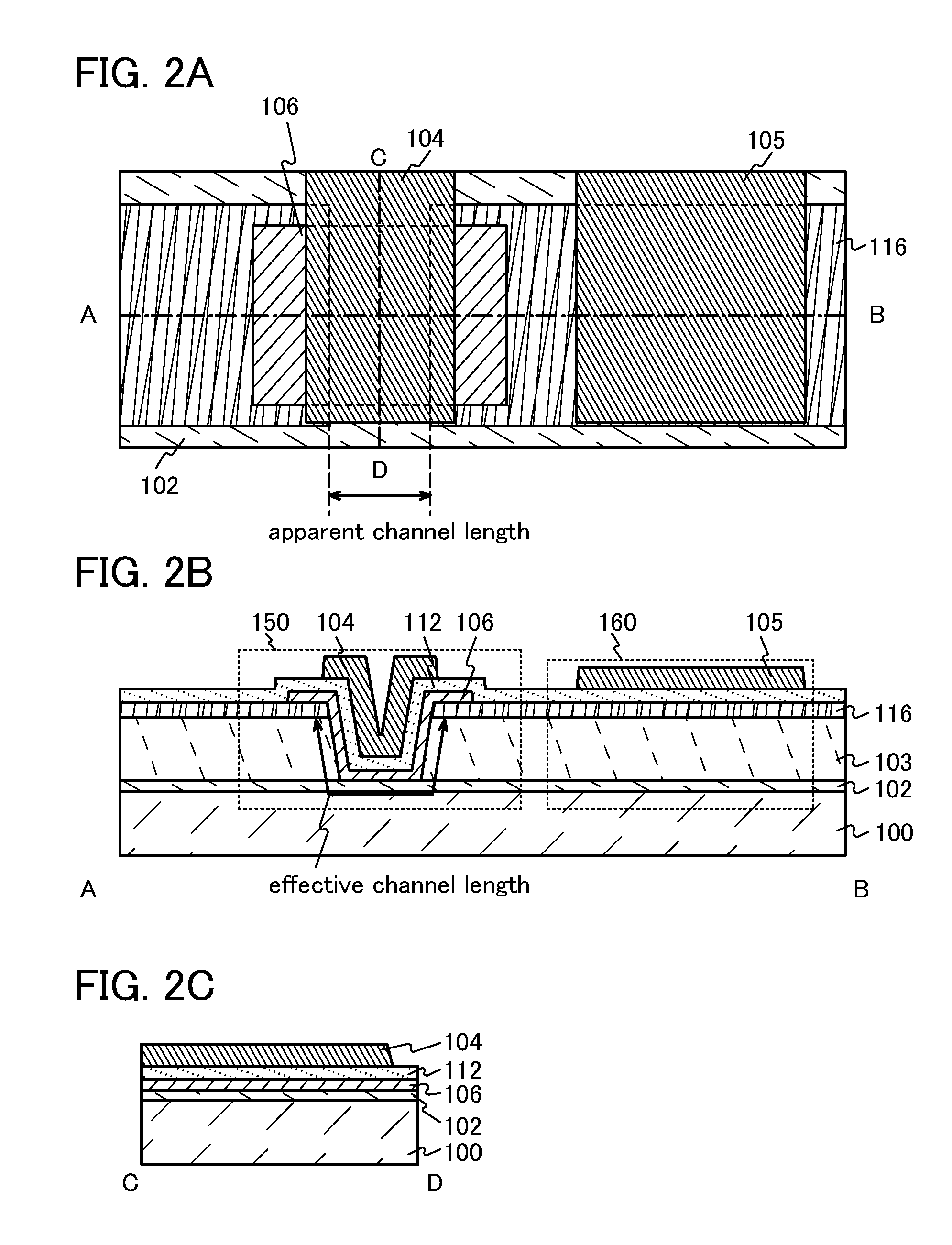

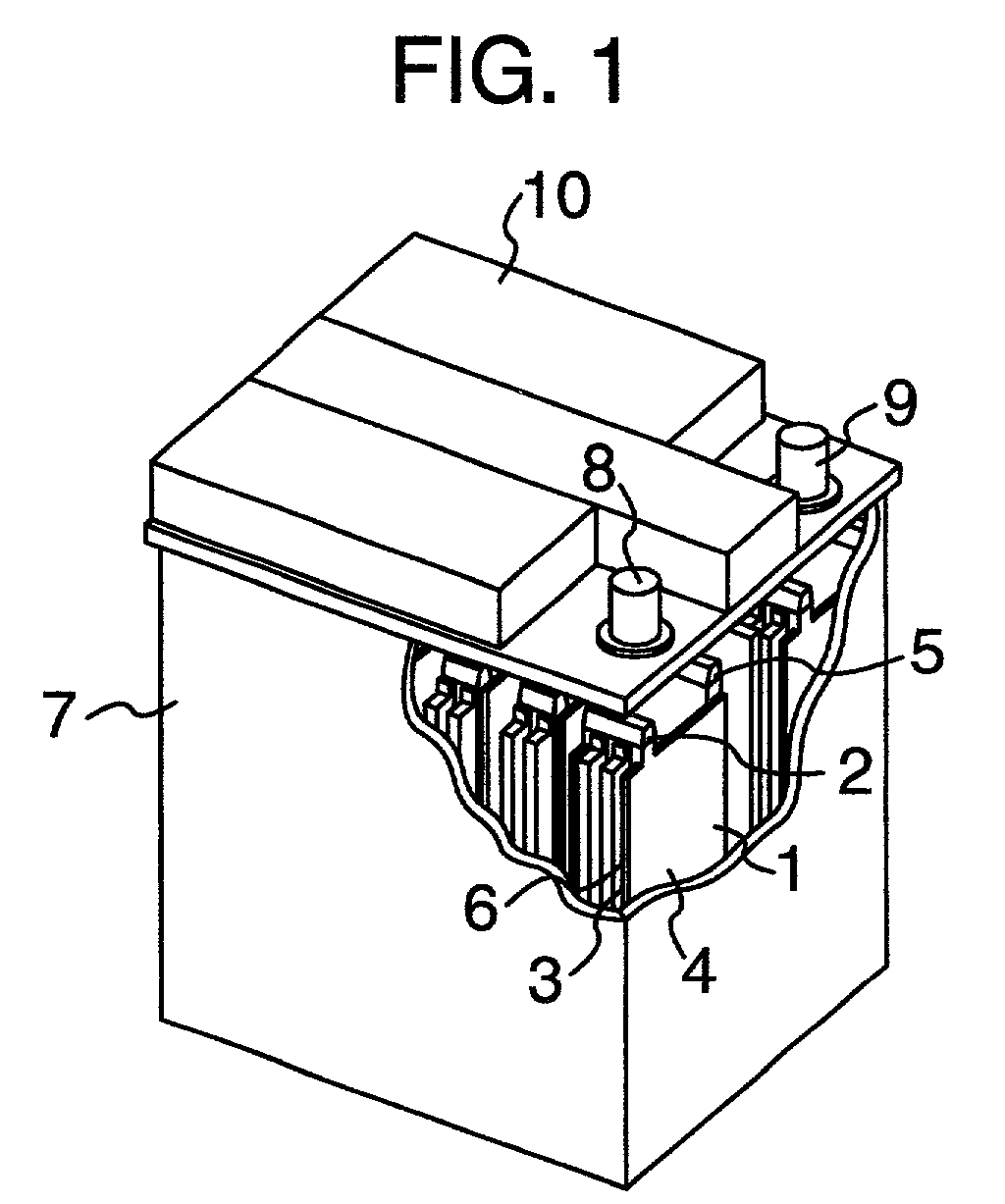

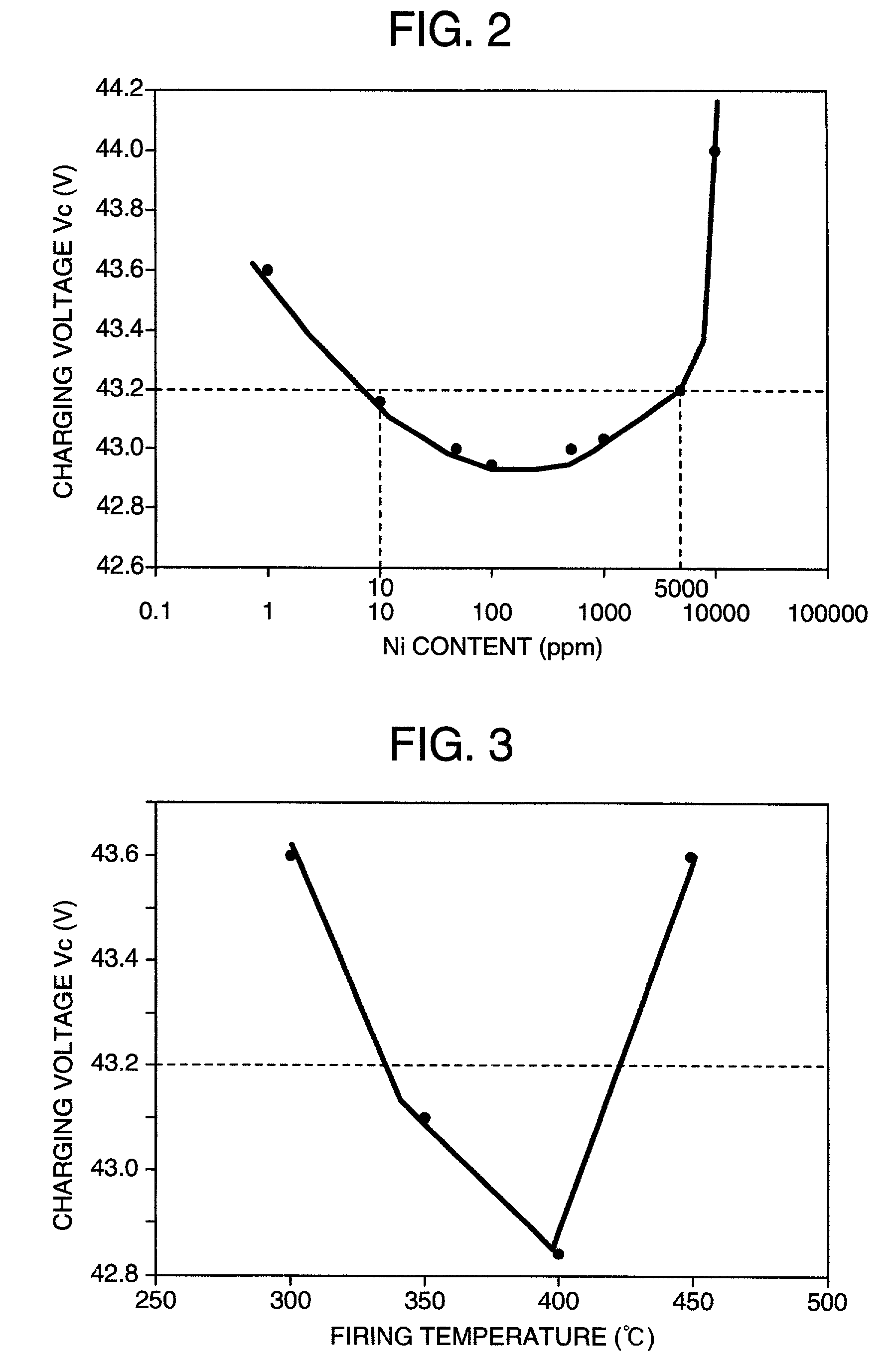

Lead-acid battery

InactiveUS20040180264A1Improve charging characteristicsImprove conductivityLead-acid accumulatorsFinal product manufactureHybrid carElectric cars

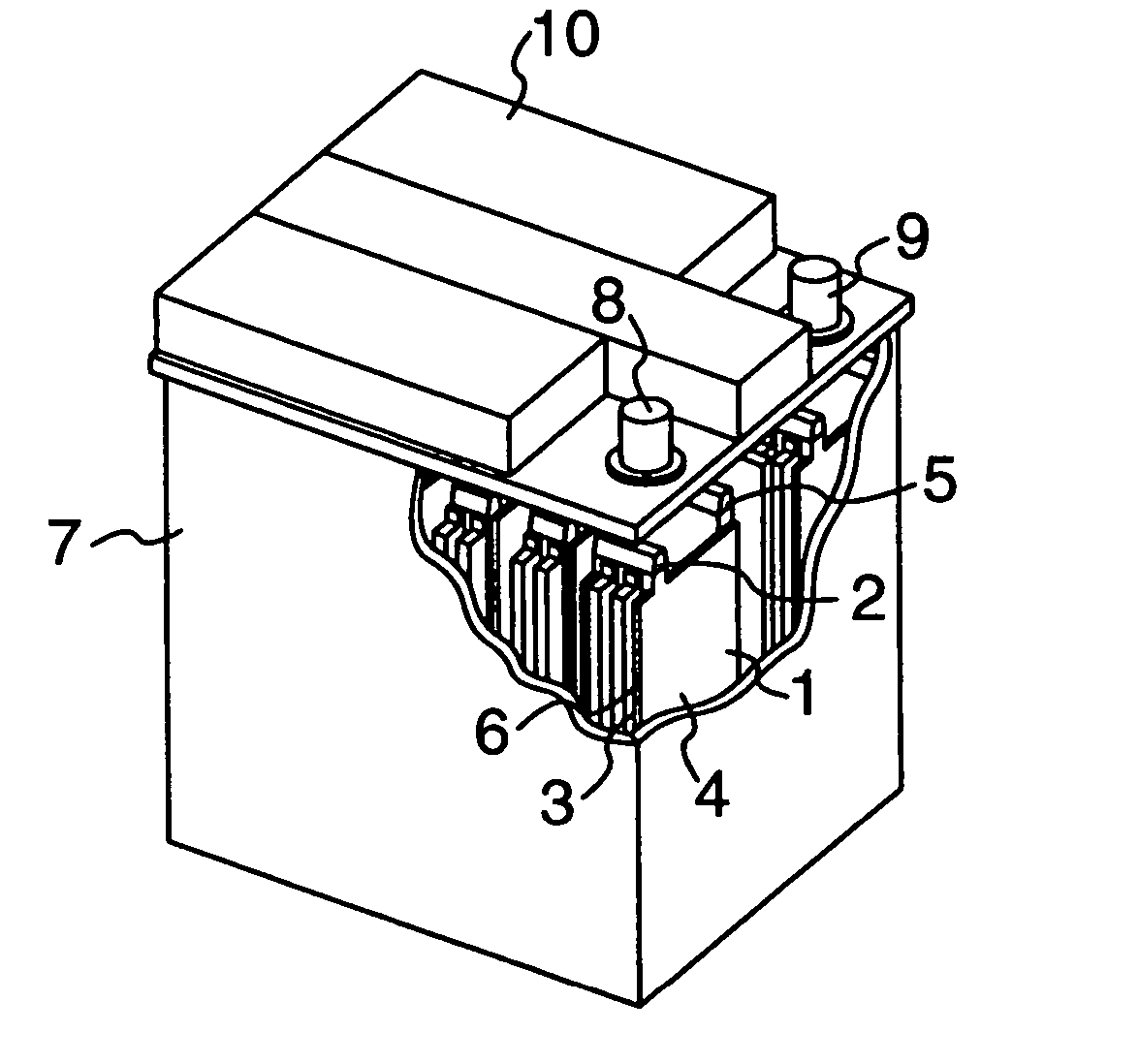

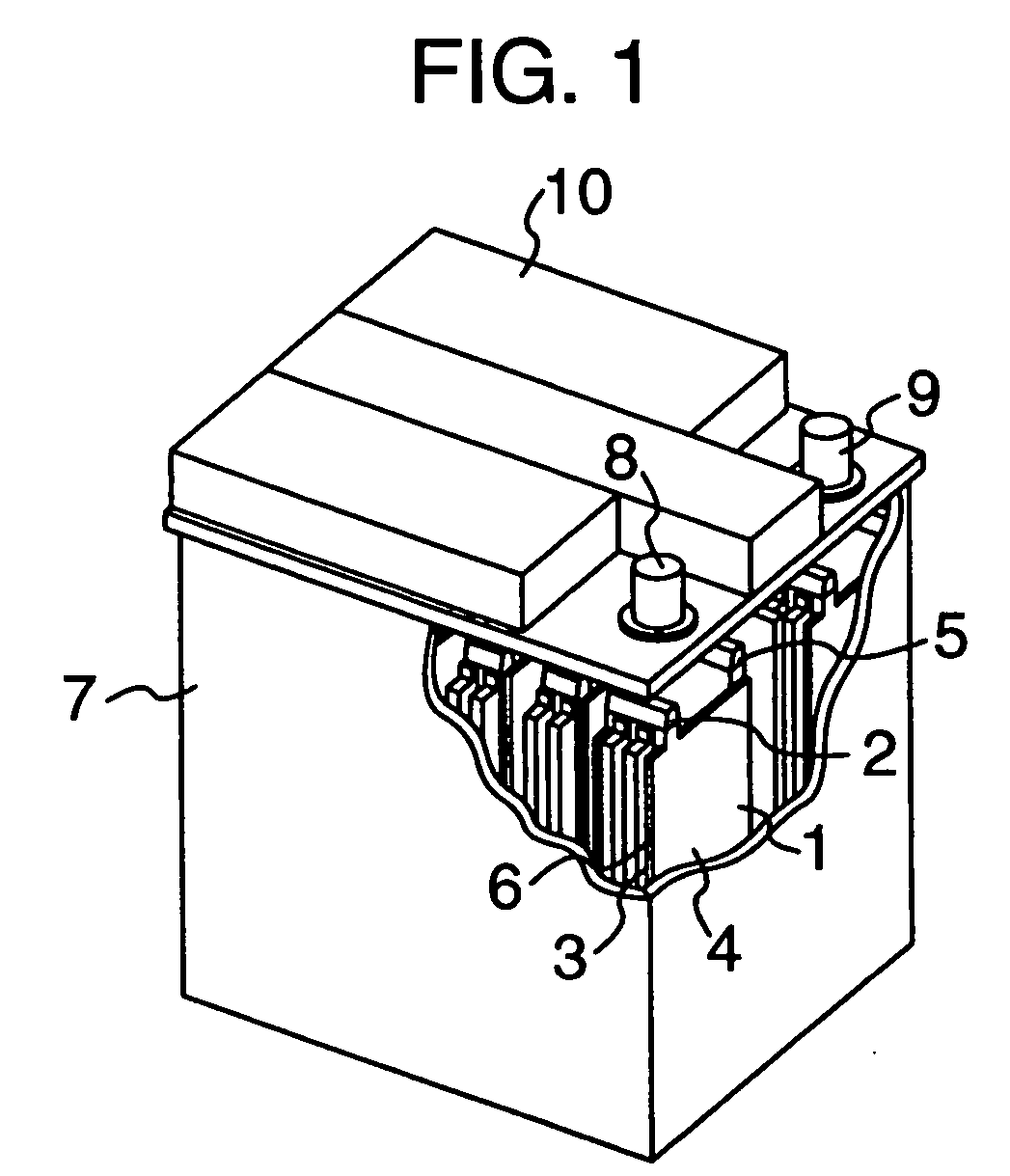

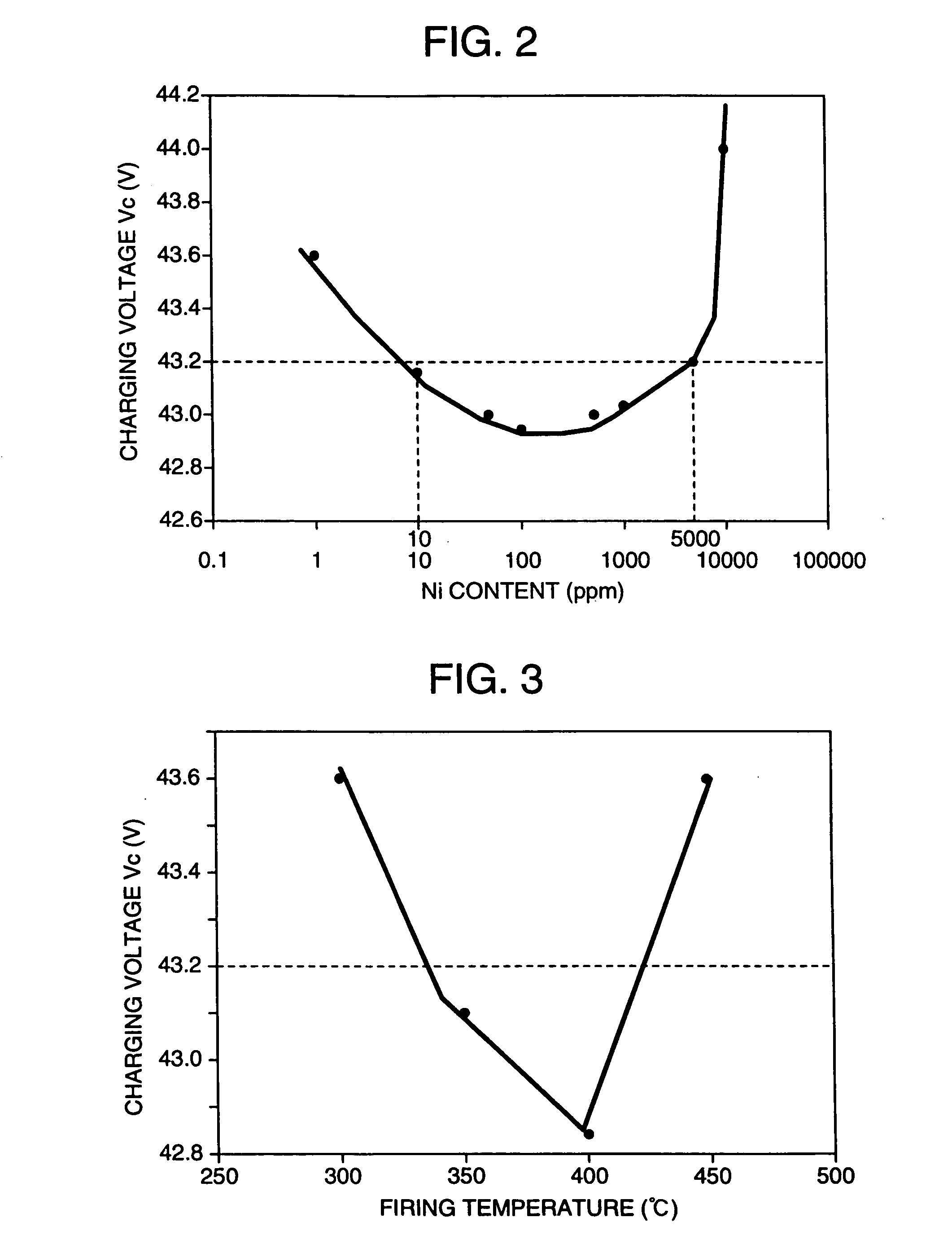

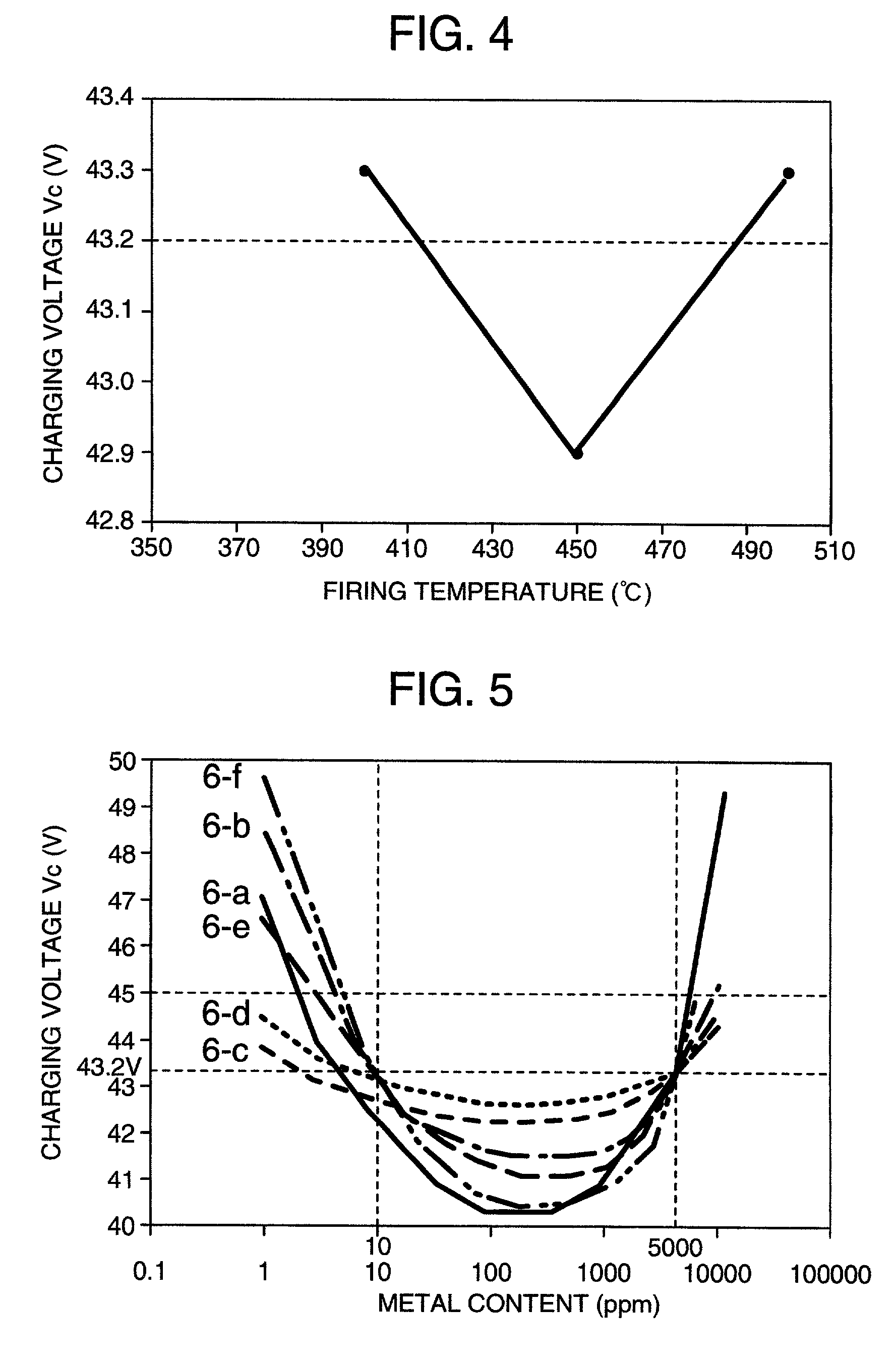

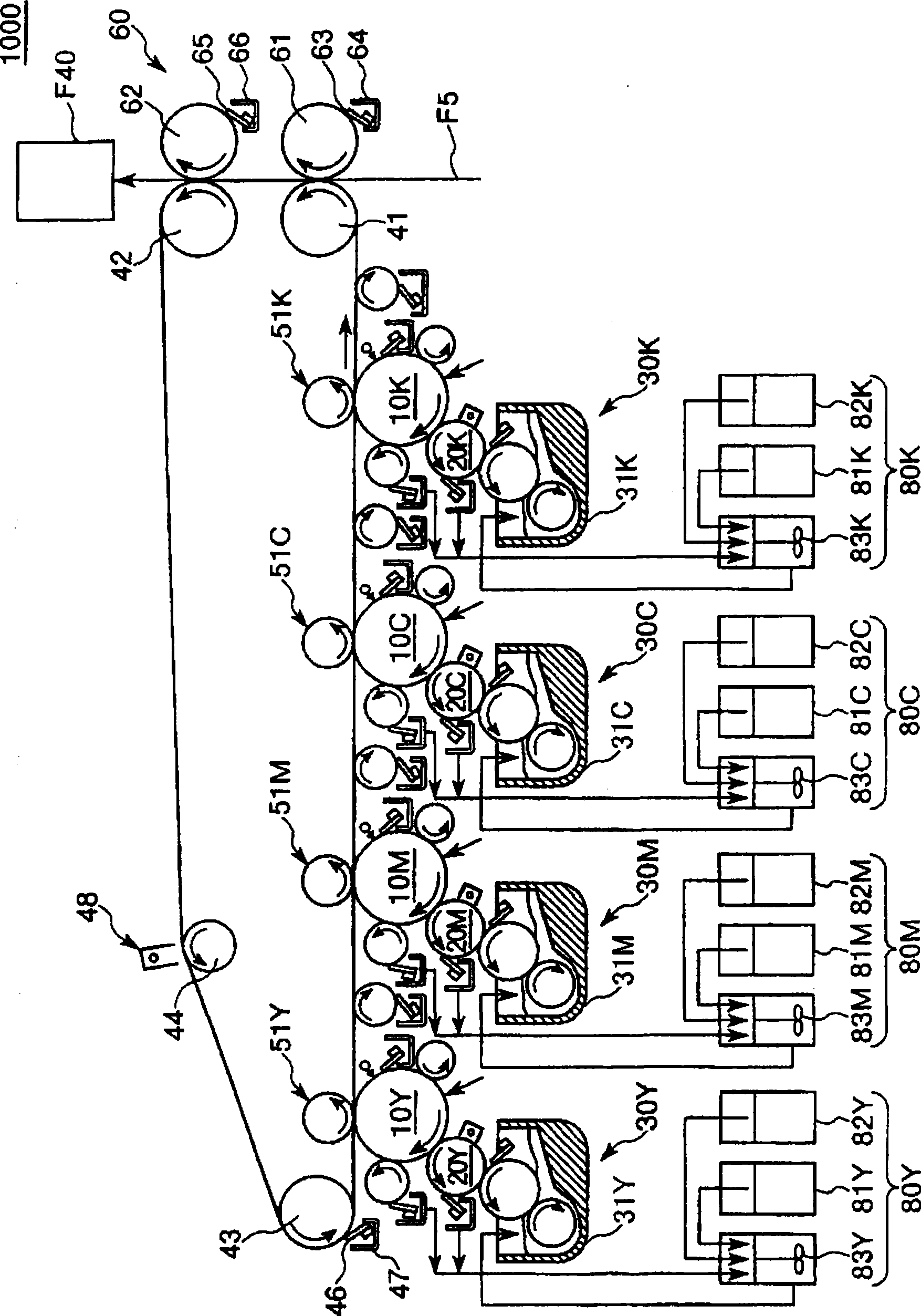

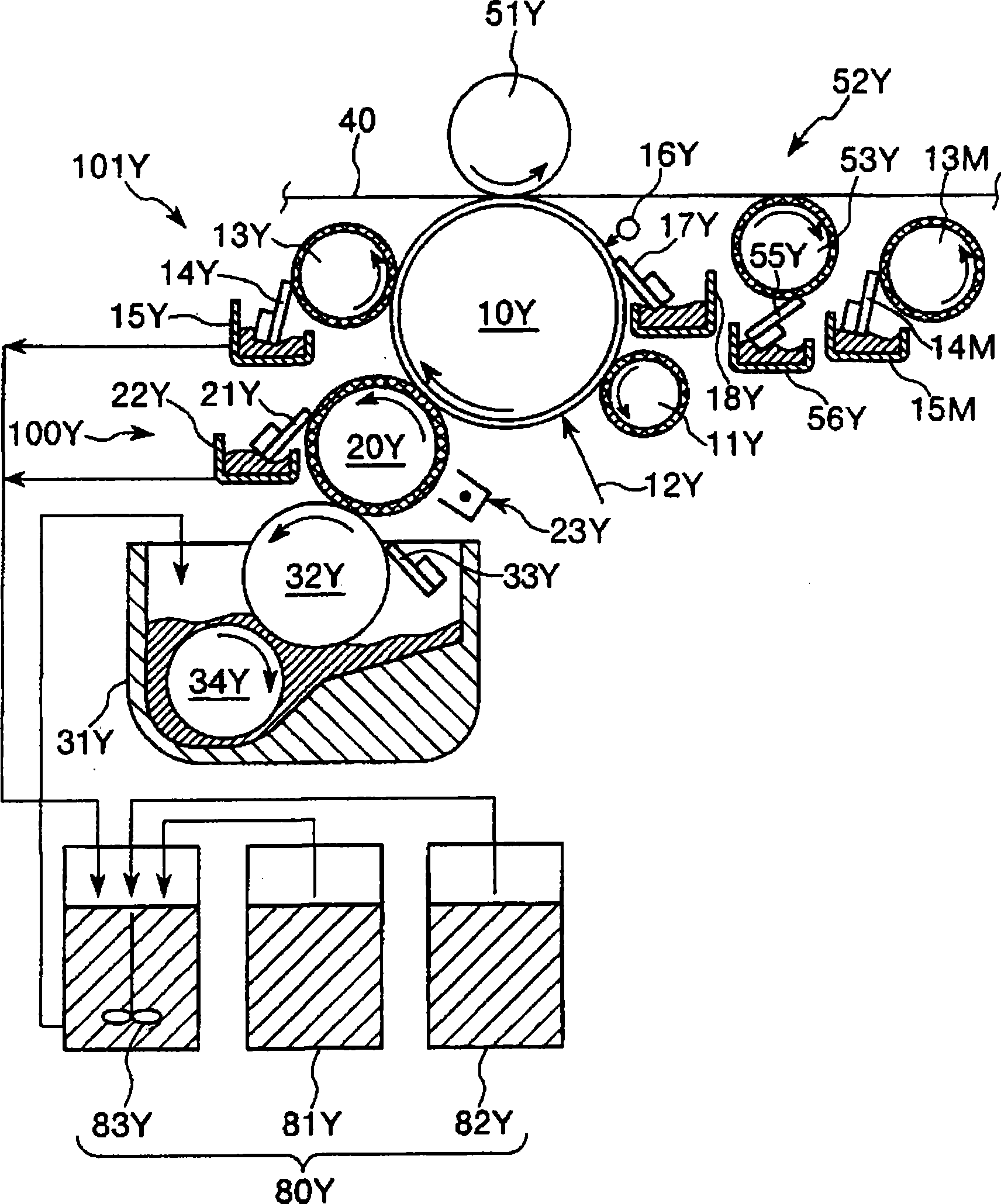

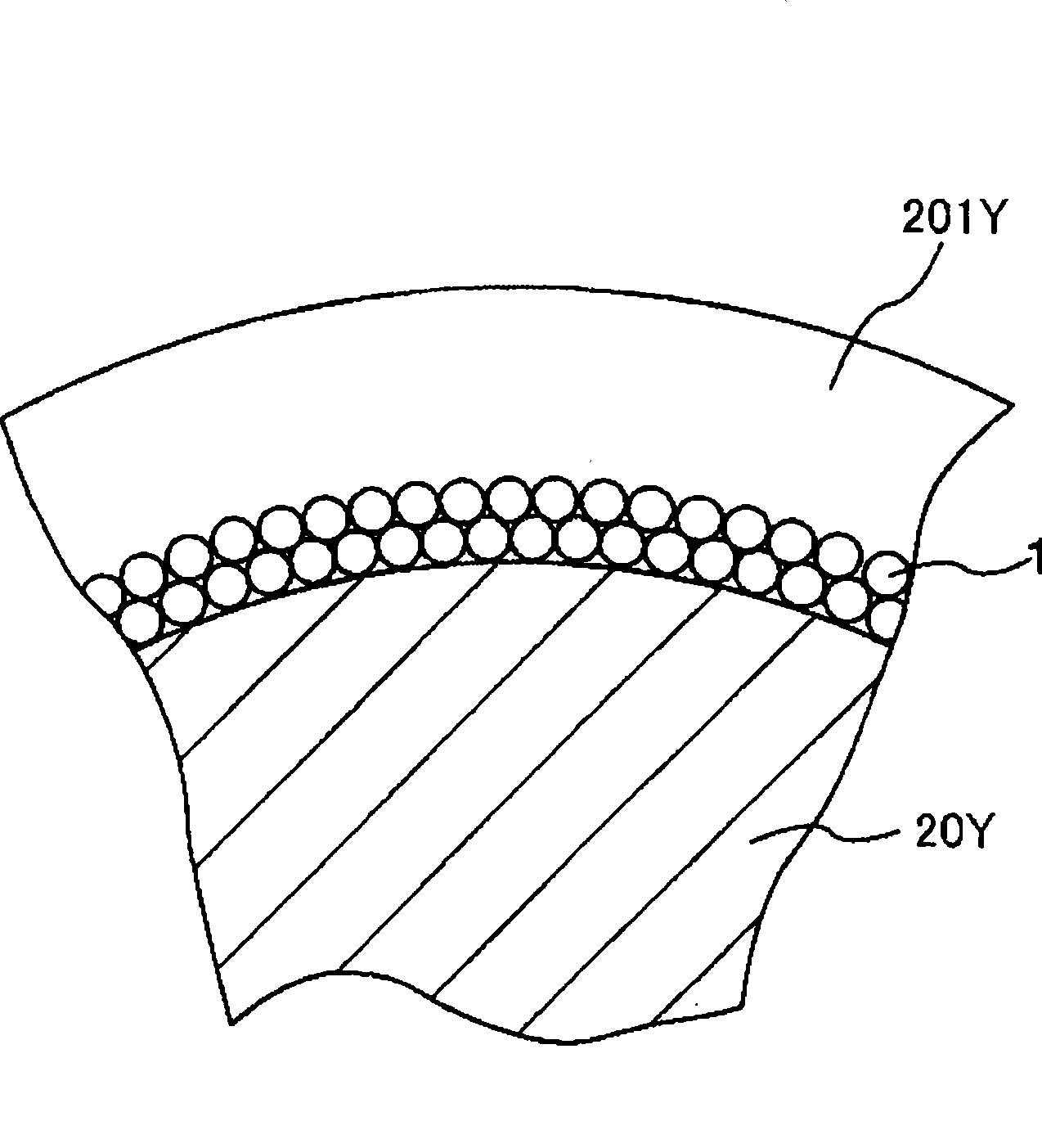

The present invention provides a lead-acid battery superior in high-efficiency charging characteristic to conventional lead-acid batteries; and a carbon material used in the lead-acid battery, having excellent charge acceptability. That is, the present invention provides a lead-acid battery which uses, as an additive to the anode active material, a simple substance and / or a compound thereof, both having a catalysis for desulfurization or a catalysis for SOx oxidation by adding to or loading on a carbon material such as active carbon, carbon black or the like and thereby has superior high-efficiency charging characteristic and improved charging acceptability. When such a lead-acid battery whose anode contains a carbon material containing or loading thereon the above simple substance and / or compound, is applied to electric cars, various hybrid cars, power storage systems, elevators, electromotive tools and power source systems such as uninterruptible power source, distributed power source and the like, all having high input and output requirements, stable control can be obtained.

Owner:HONBO KYOKO +3

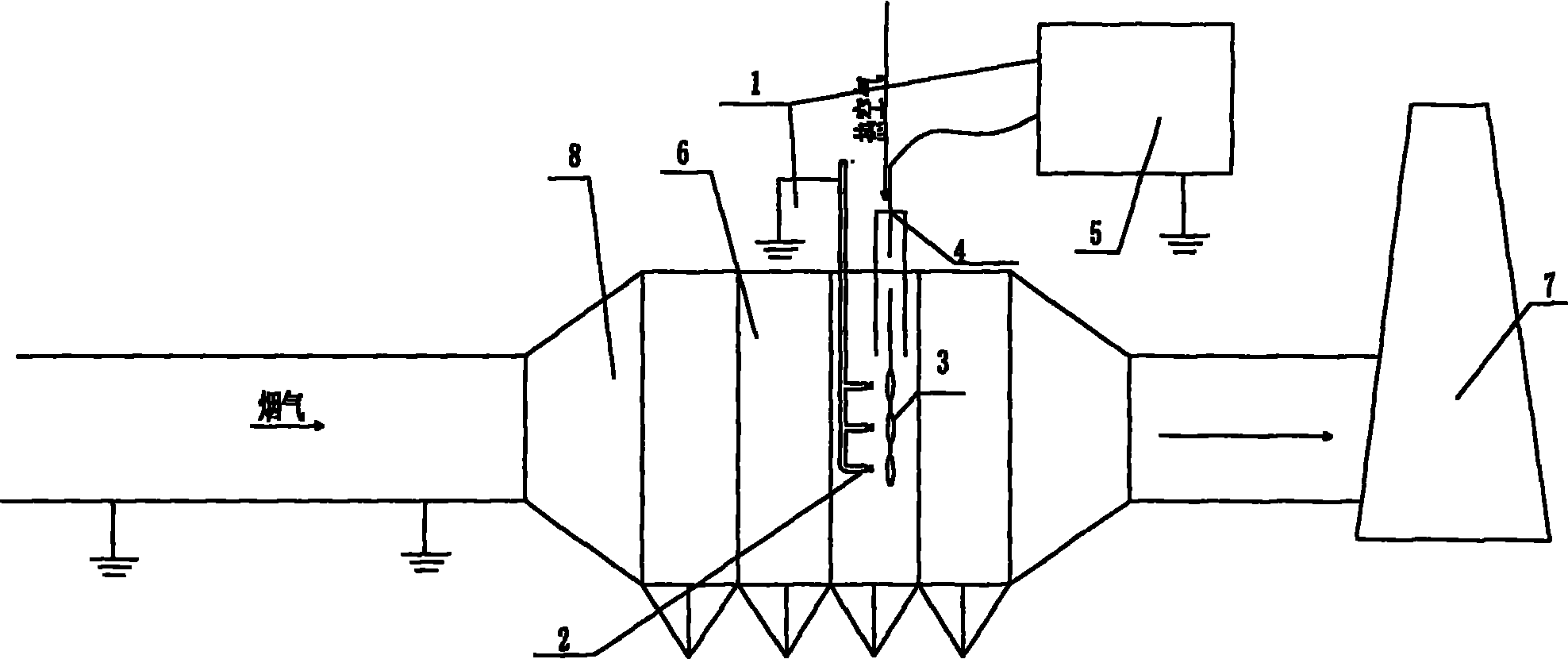

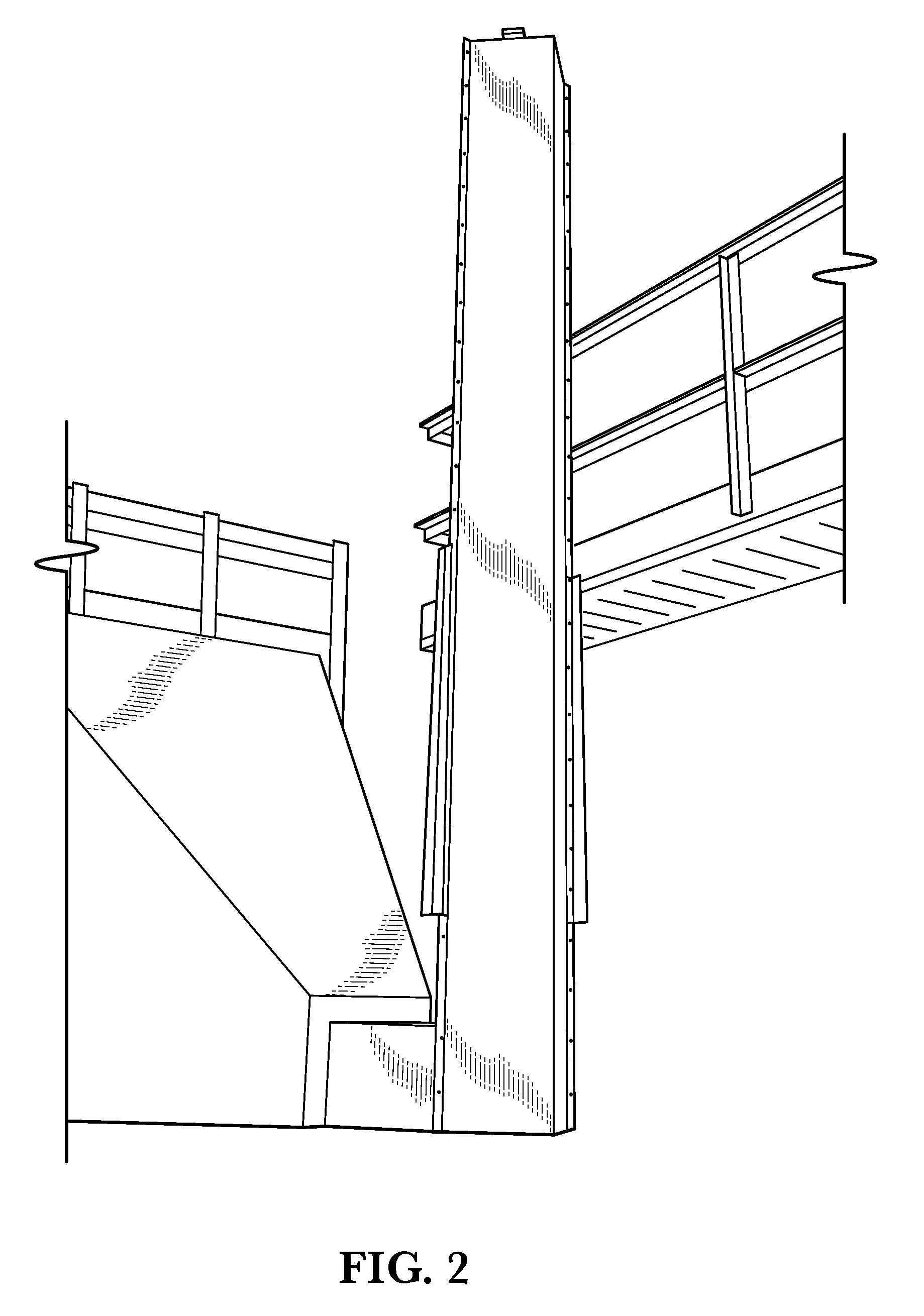

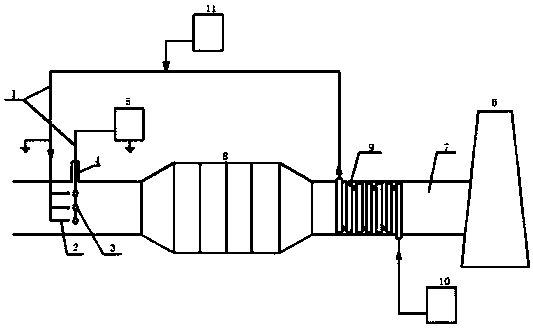

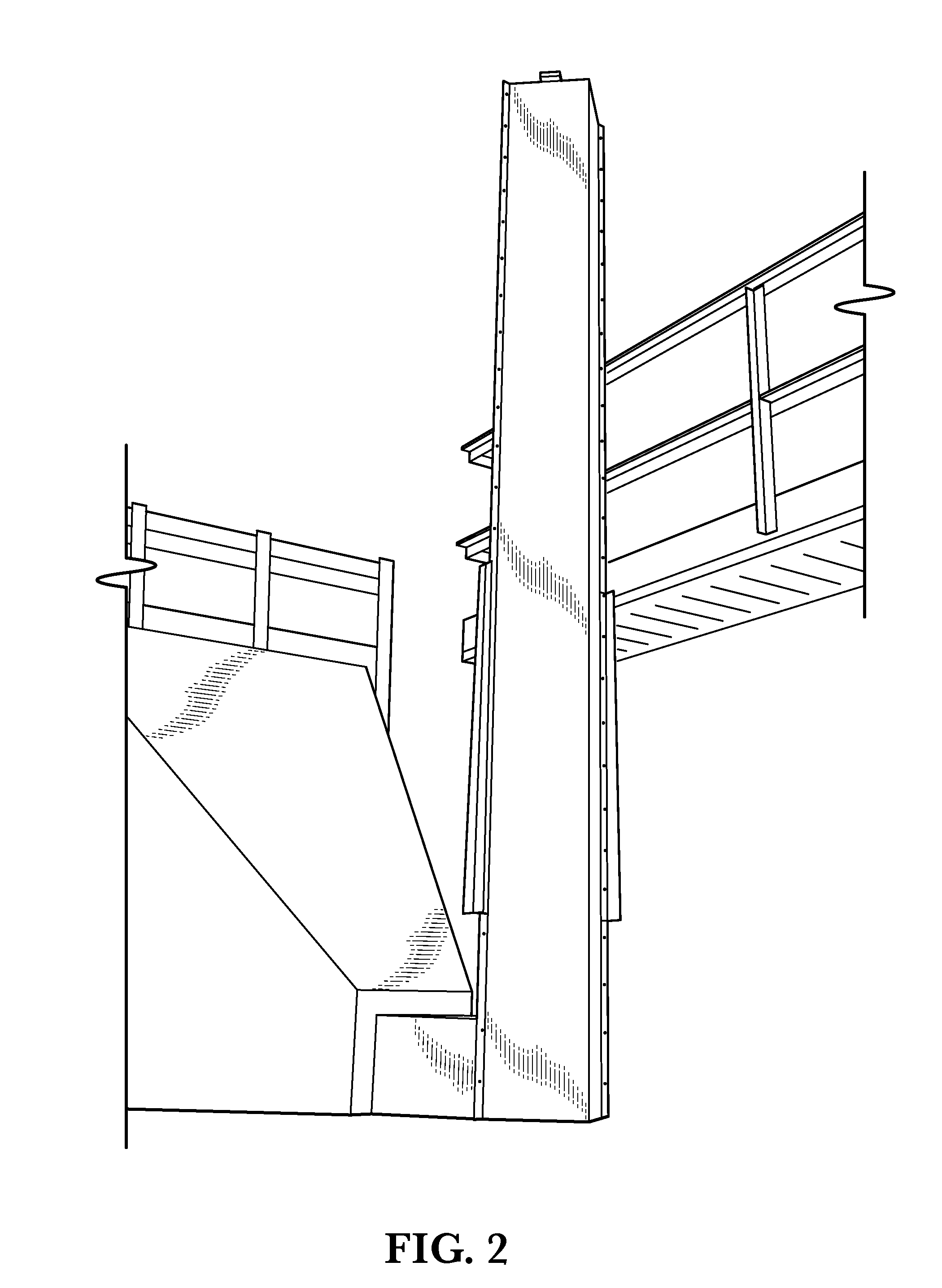

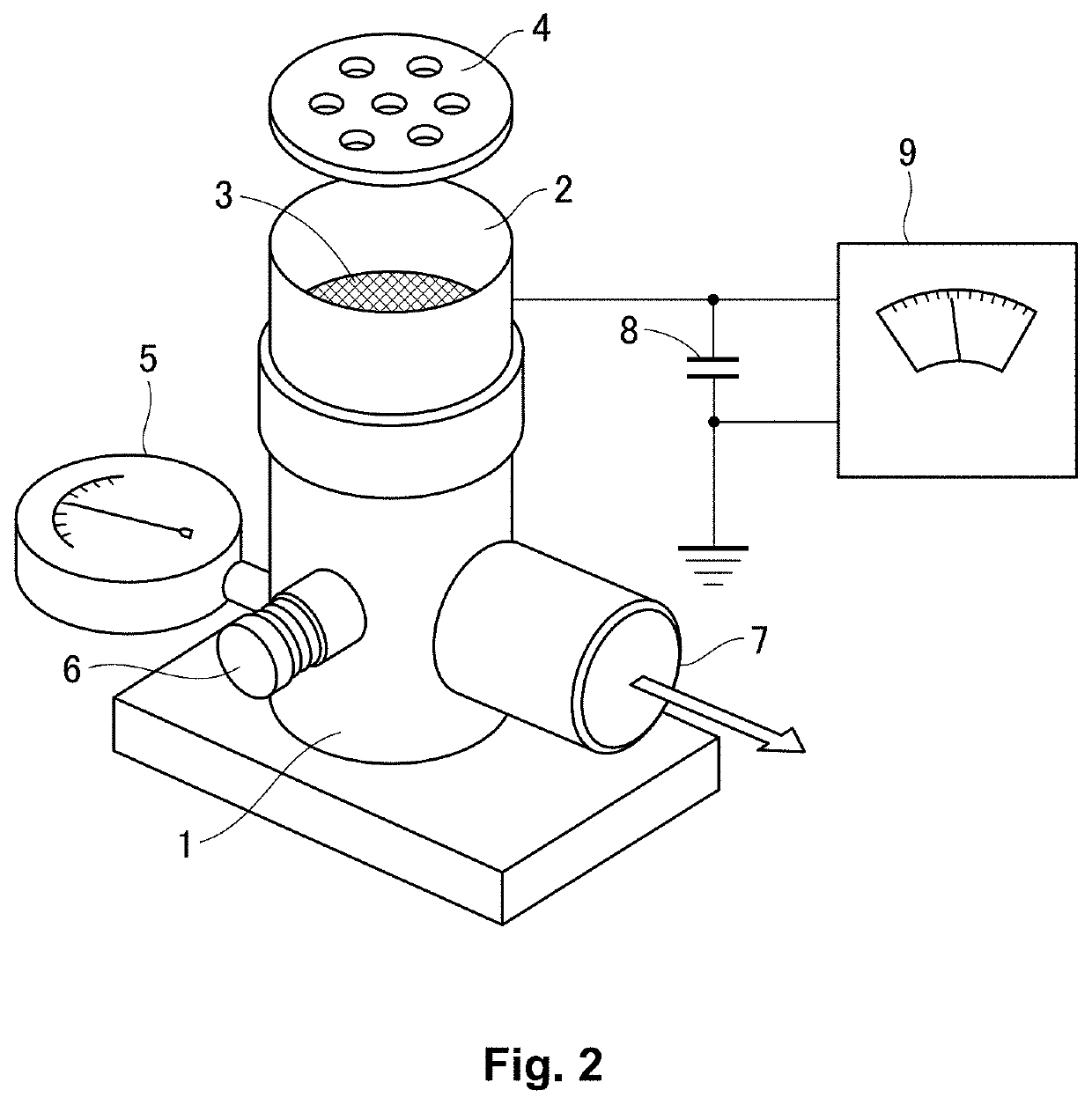

Synergistic spray charging and electrostatic dust collecting method and device

InactiveCN102145316AIncreased viscosityPromote reunionElectrostatic separationElectrostatic precipitatorDust particles

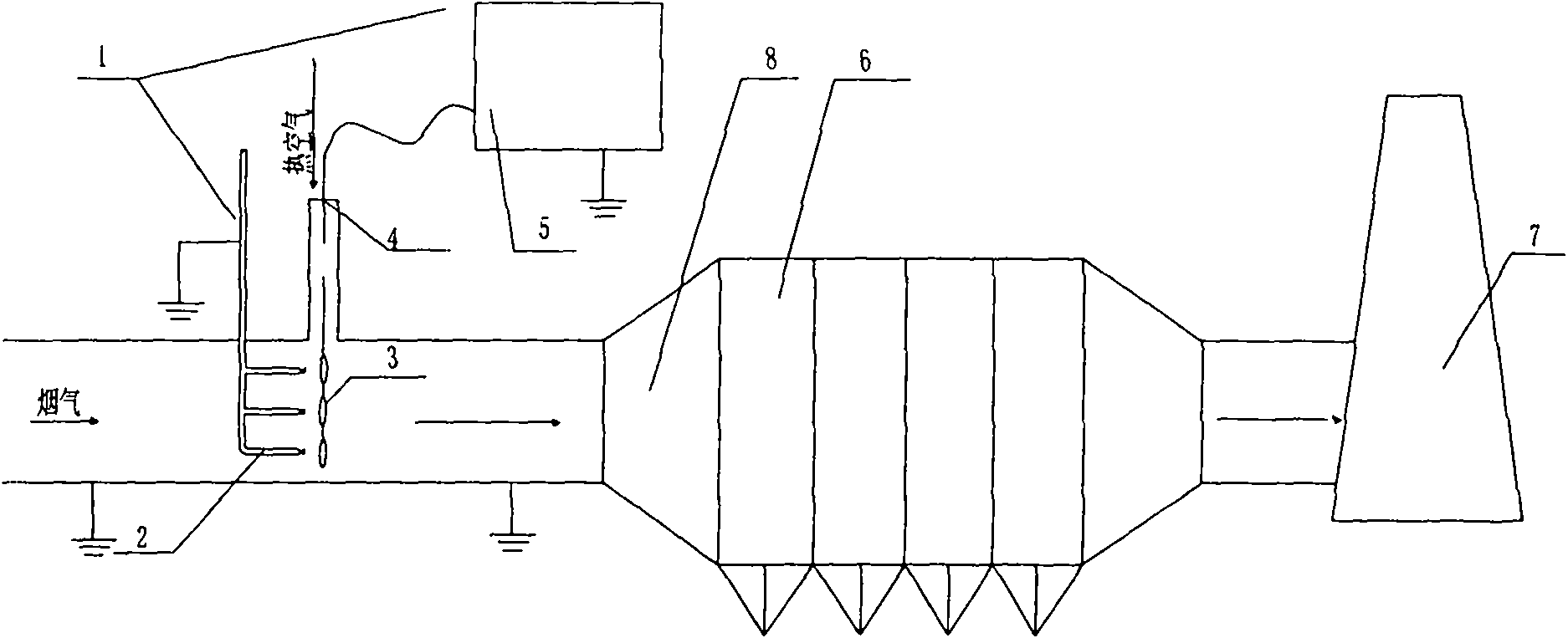

The invention relates to a synergistic spray charging and electrostatic dust collecting method by which a water spray charging device is combined with an electrostatic dust collector, flue gas is conditioned by using water spray, agglomeration of dust particles is promoted and the charging characteristic of the dust particles is improved through charging drops containing an agglomerating agent, thus the dust collection efficiency of the electrostatic dust collector is increased, the fine dust collecting efficiency is higher than 90 percent, and the concentration of smoke dust at an outlet is lower than 50 milligrams per cubic meter. The invention also discloses a synergistic spray charging and electrostatic dust collecting device which comprises the electrostatic dust collector and the water spray charging device, wherein the electrostatic dust collector is arranged on a flue; and the water spray charging device is arranged on a flue in front of an inlet of the electrostatic dust collector, or on a gradually expanded section of the inlet or on a position of a bottom second-stage or third-stage electric field in the electrostatic dust collector. The water spray charging device comprises a dual-fluid atomizing nozzle and a corona ring, wherein the dual-fluid atomizing nozzle is arranged at the front part of the corona ring, an insulator is arranged outside the upper end of the corona ring, and the corona ring is connected with a high-voltage power supply through a wire. The synergistic spray charging and electrostatic dust collecting device has a simple structure, low cost and high dust collecting efficiency.

Owner:SHANDONG UNIV

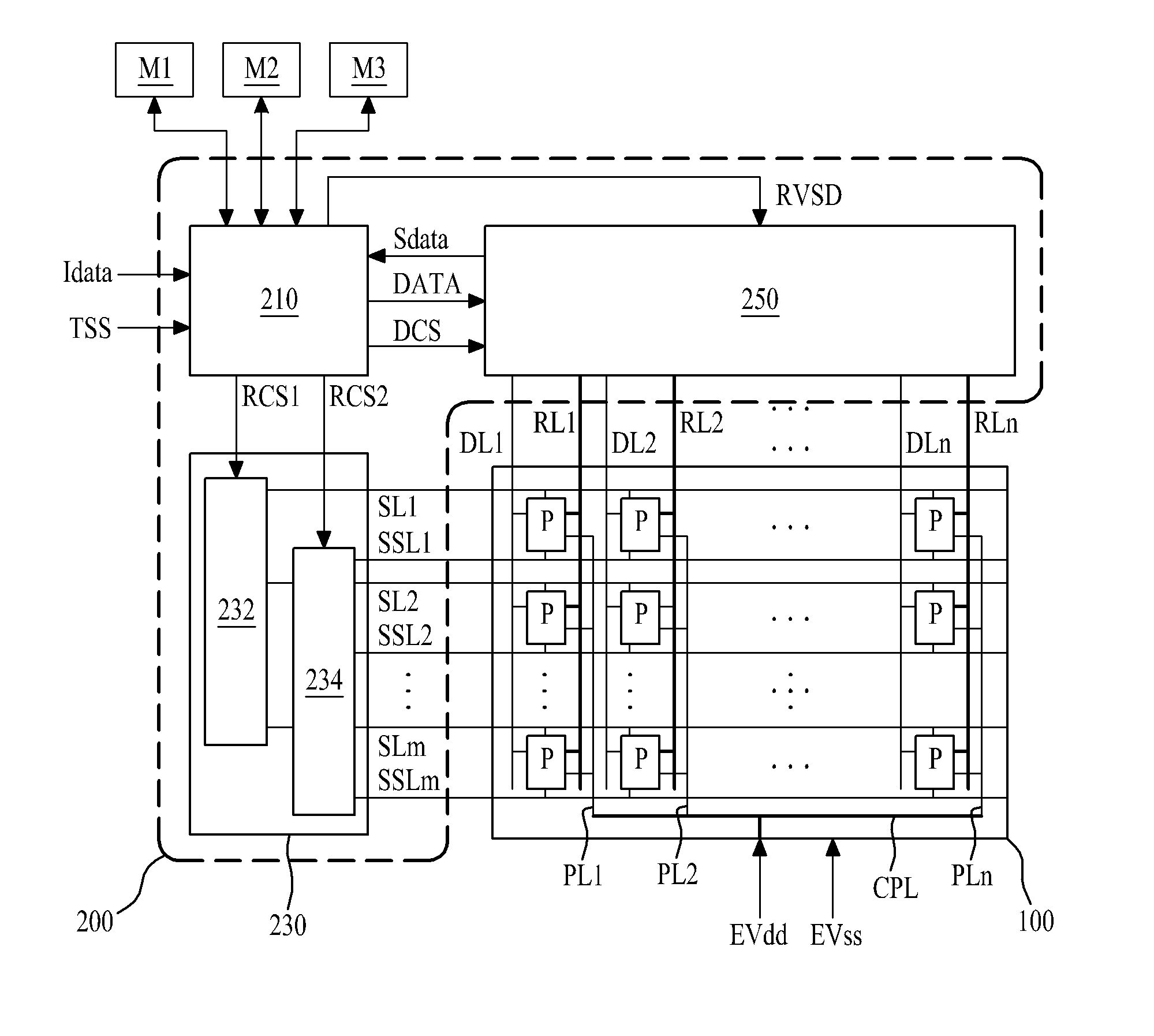

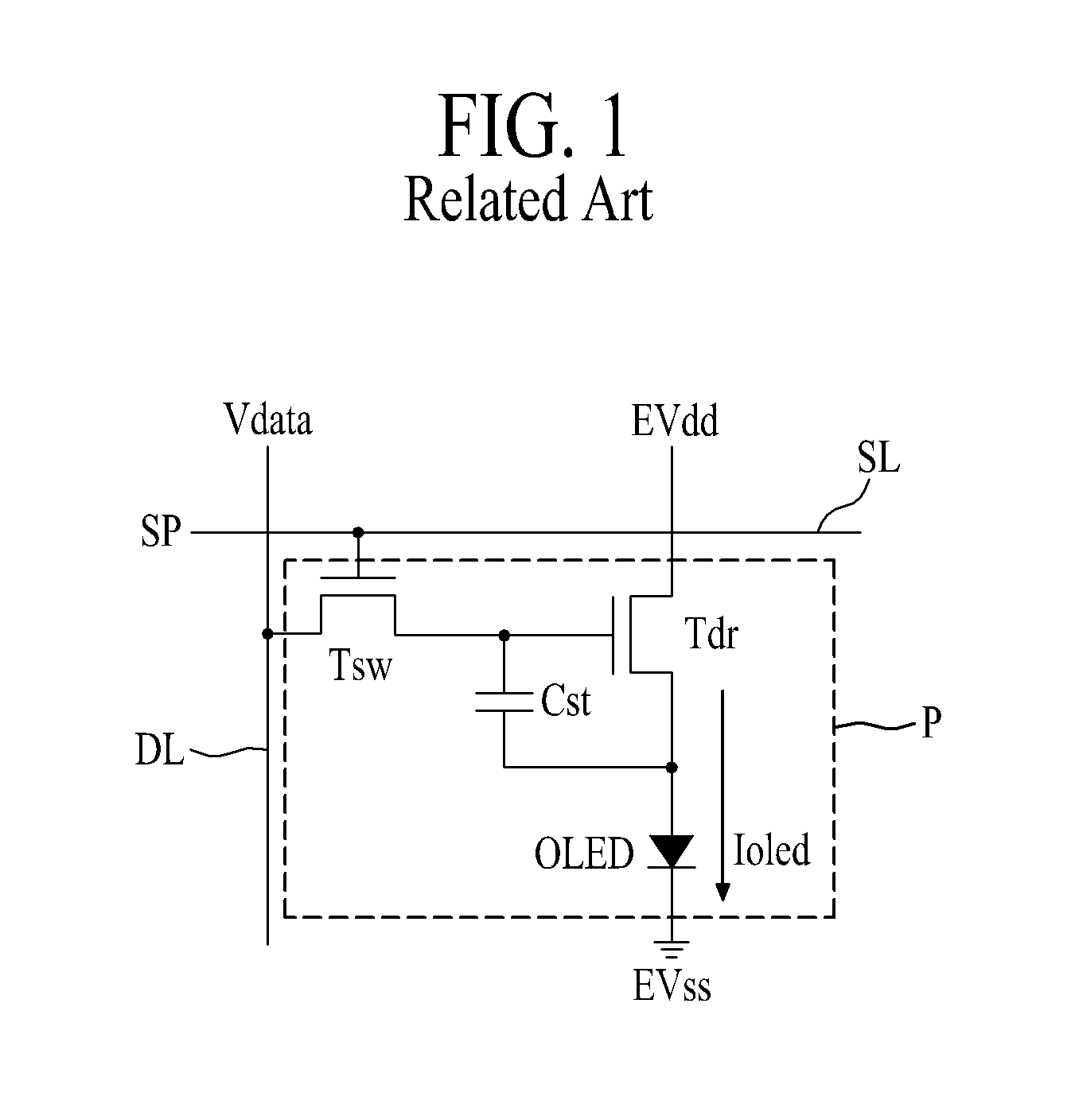

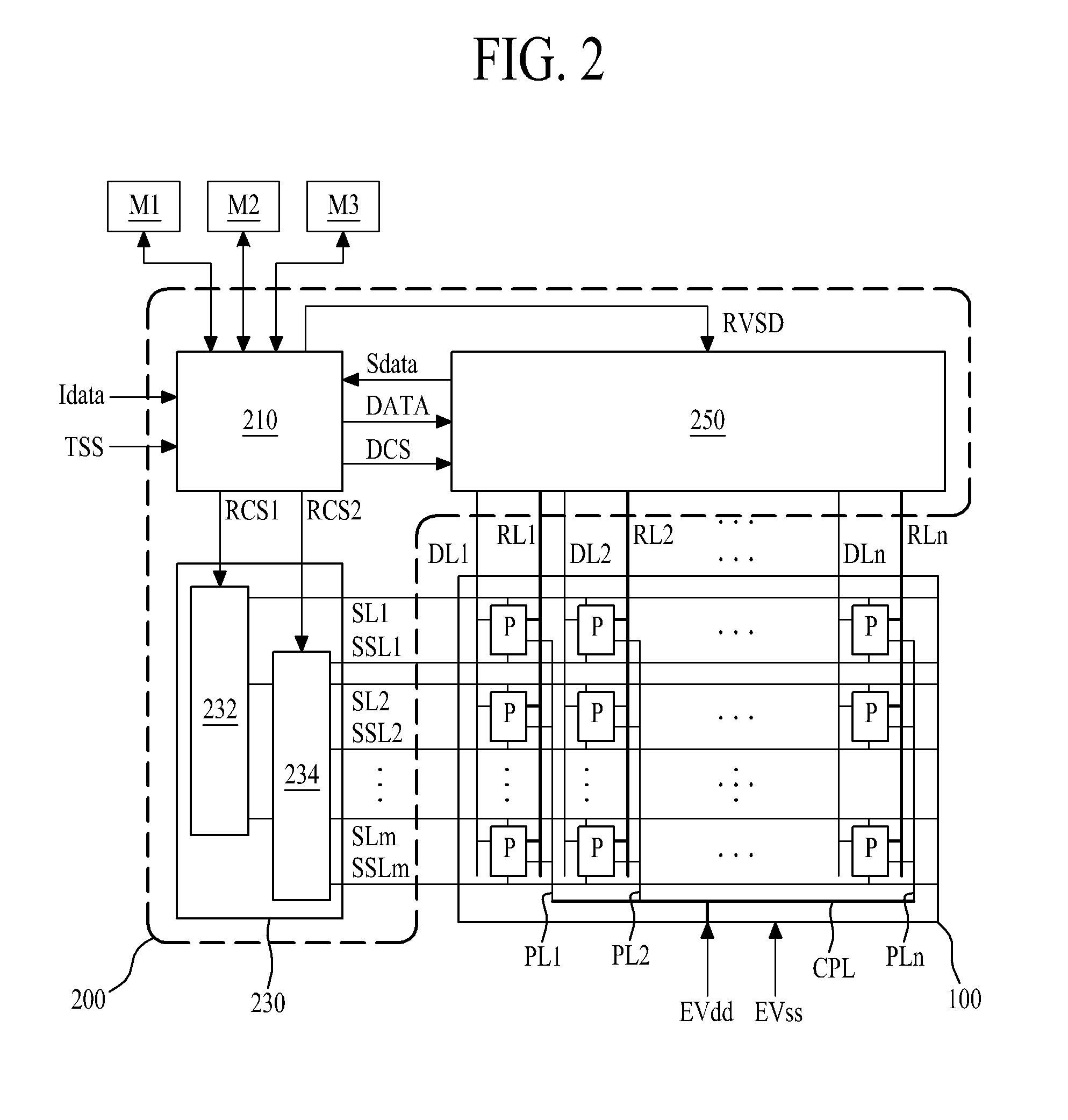

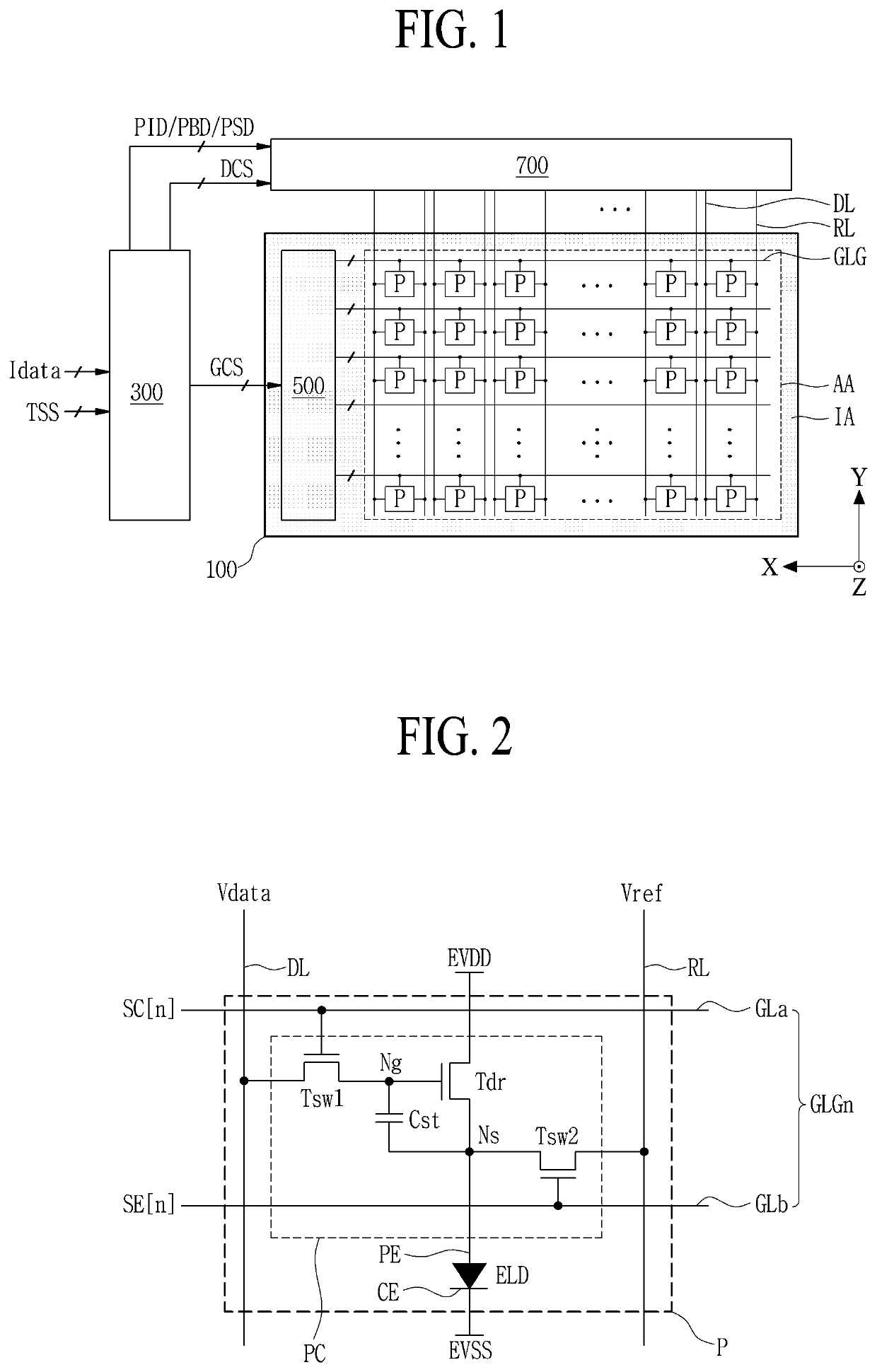

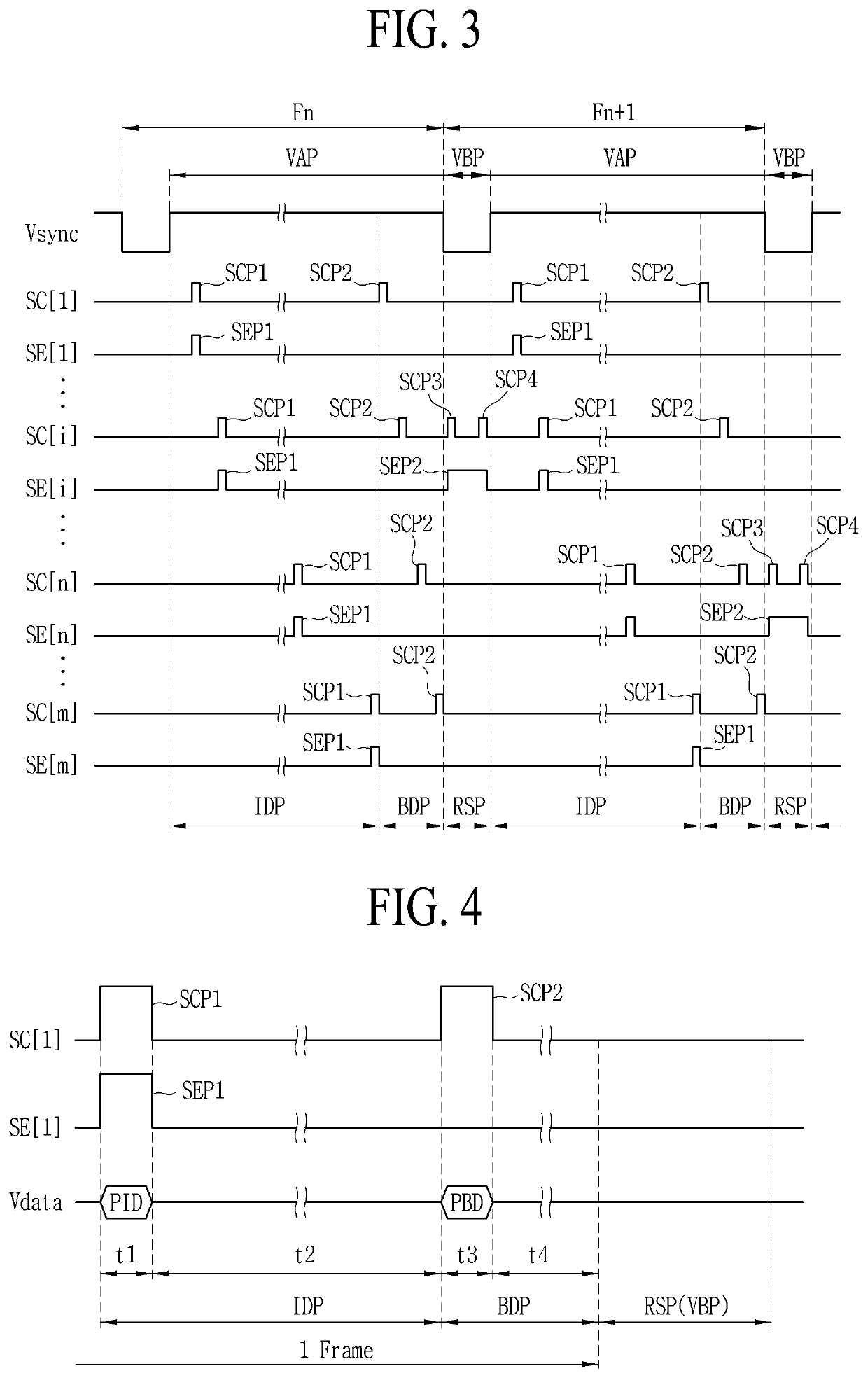

Organic light emitting display device

ActiveUS20150179107A1Uniform brightnessImprove brightness uniformityCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceVoltage reference

An organic light emitting display device includes a display panel which is operated in a sensing mode or display mode and is provided with a plurality of sub-pixels, wherein each sub-pixel includes a driving transistor driven in accordance with a differential voltage between data and reference voltages, and an organic light emitting diode which emits light by a current flowing in accordance with driving of the driving transistor; a first memory for storing a characteristic value of the driving transistor sensed from the sub-pixel by the sensing mode; and a panel driver for generating the reference voltage based on the characteristic value of the driving transistor for the display mode.

Owner:LG DISPLAY CO LTD

Lead-acid battery

InactiveUS20030049528A1Improved high-efficiency charging characteristicImprove charging characteristicsLead-acid accumulatorsFinal product manufactureHybrid carElectric cars

The present invention provides a lead-acid battery superior in high-efficiency charging characteristic to conventional lead-acid batteries; and a carbon material used in the lead-acid battery, having excellent charge acceptability. That is, the present invention provides a lead-acid battery which uses, as an additive to the anode active material, a simple substance and / or a compound thereof, both having a catalysis for desulfurization or a catalysis for SOX oxidation by adding to or loading on a carbon material such as active carbon, carbon black or the like and thereby has superior high-efficiency charging characteristic and improved charging acceptability. When such a lead-acid battery whose anode contains a carbon material containing or loading thereon the above simple substance and / or compound, is applied to electric cars, various hybrid cars, power storage systems, elevators, electromotive tools and power source systems such as uninterruptible power source, distributed power source and the like, all having high input and output requirements, stable control can be obtained.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

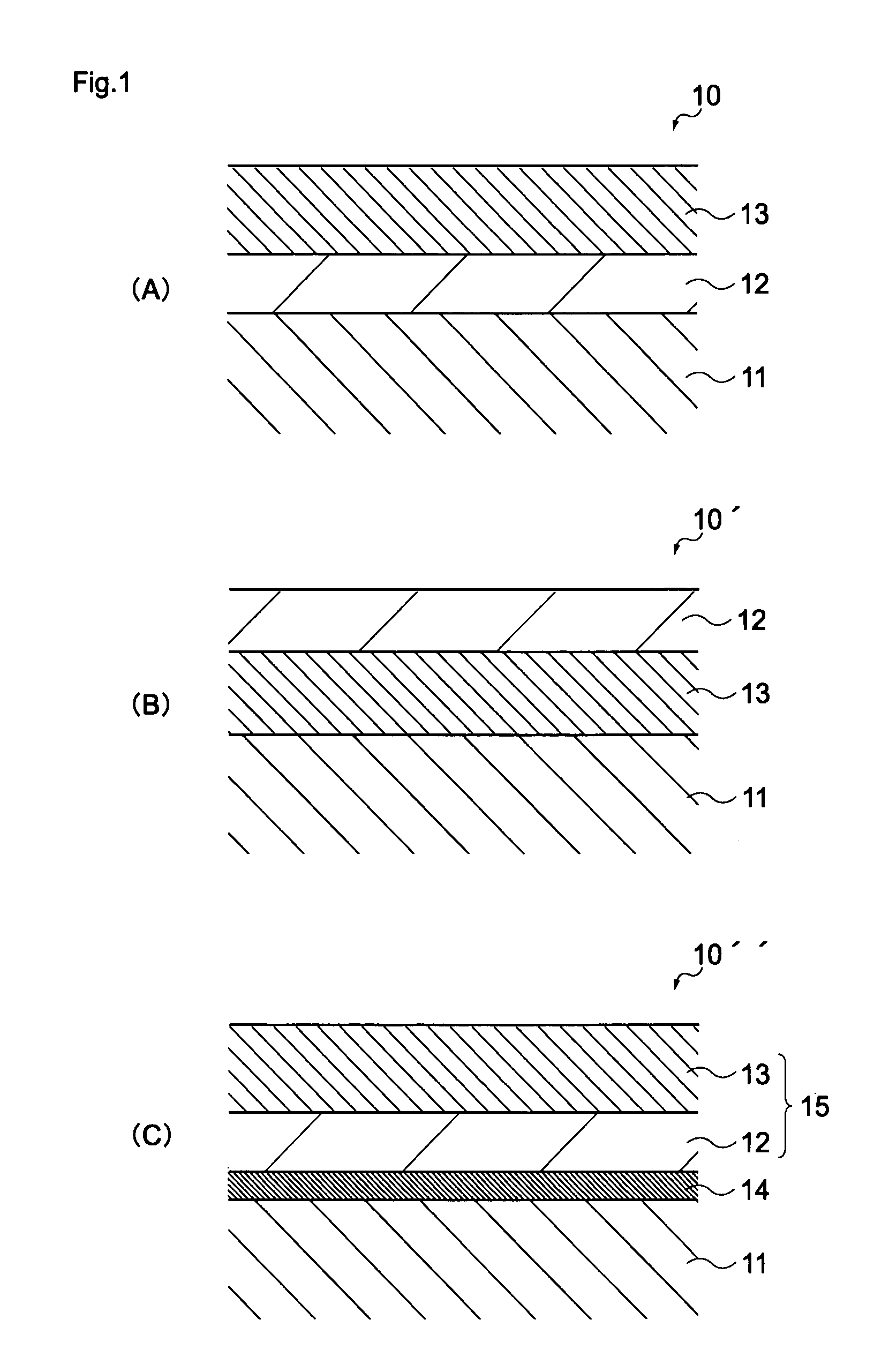

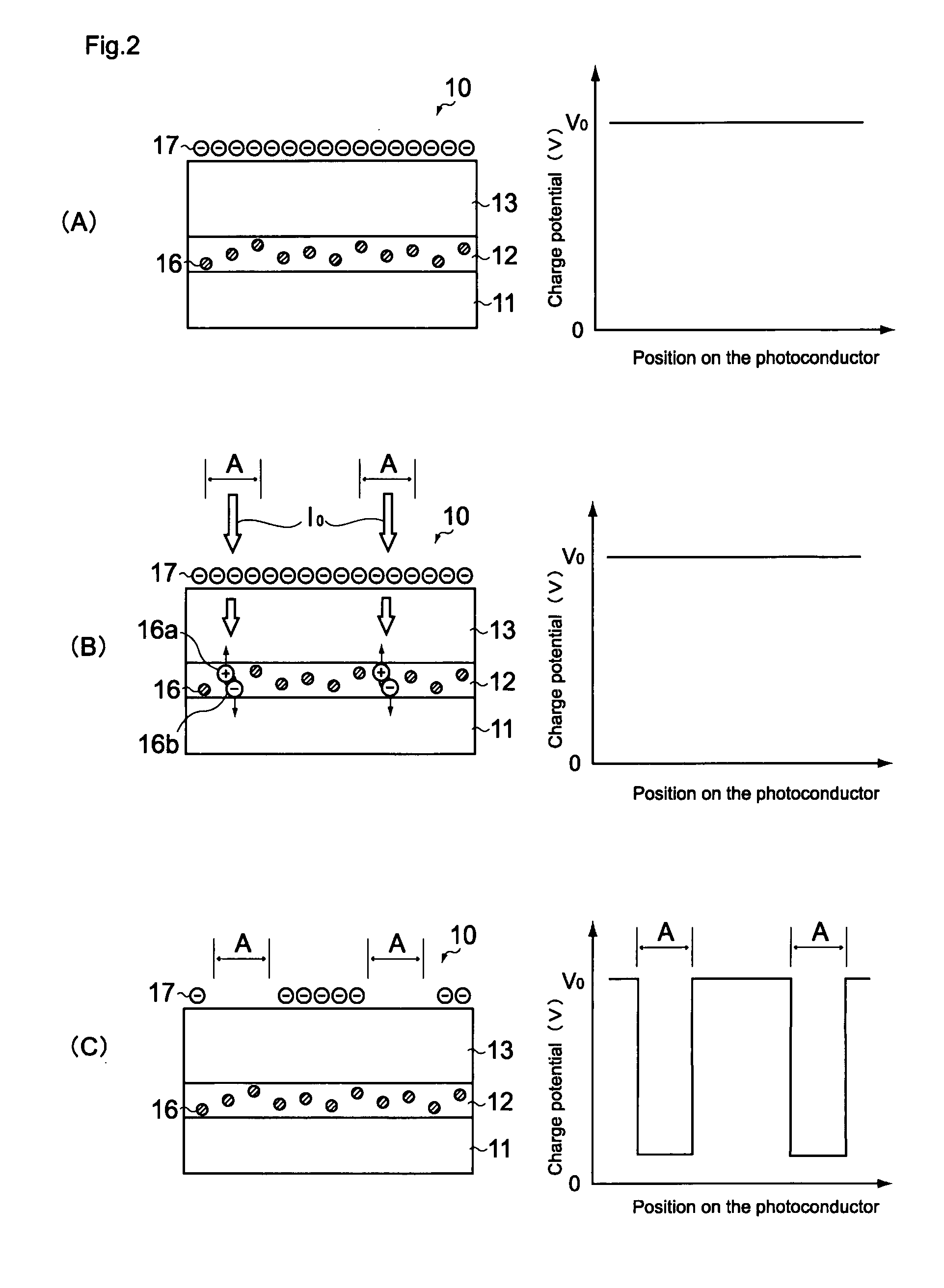

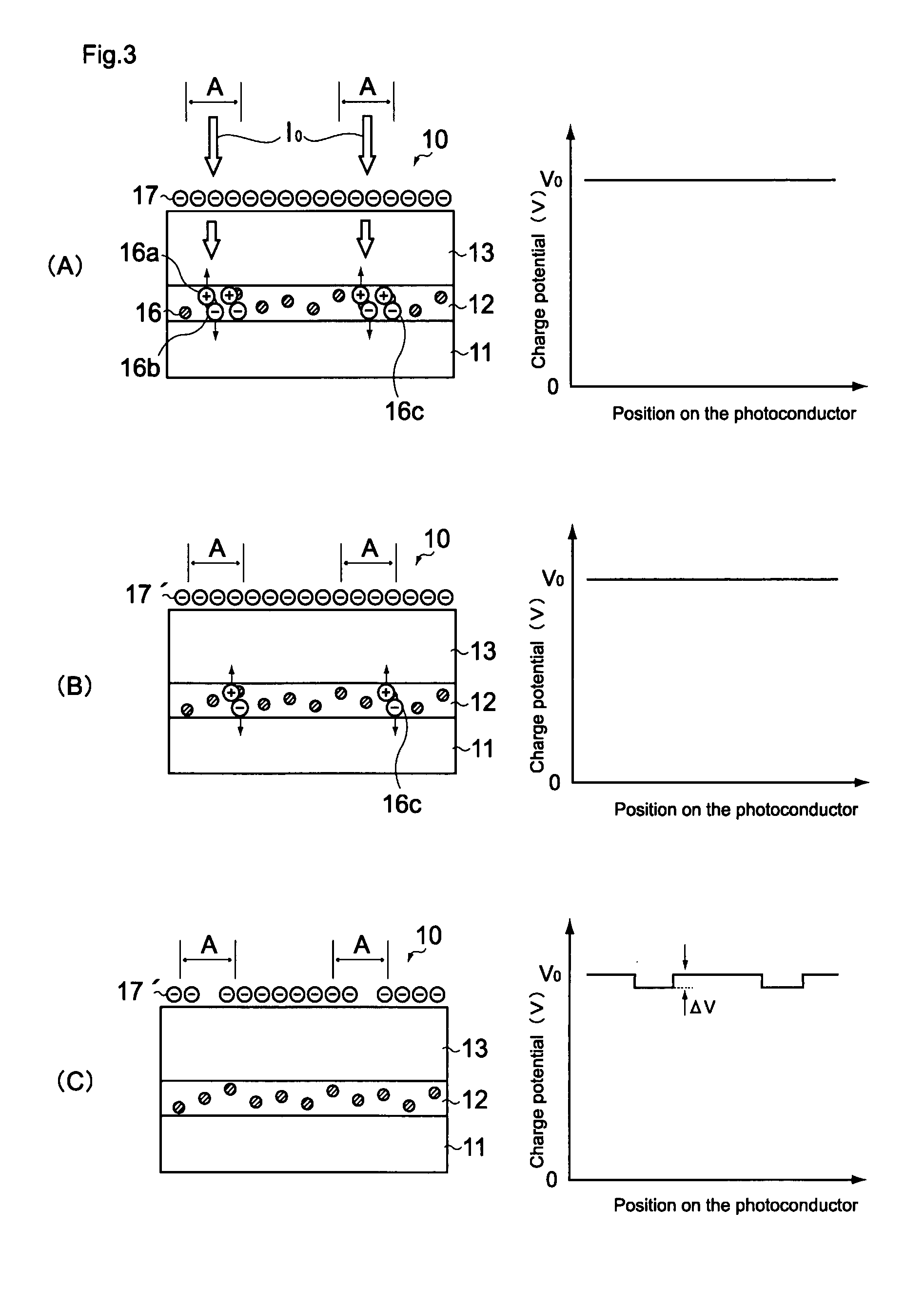

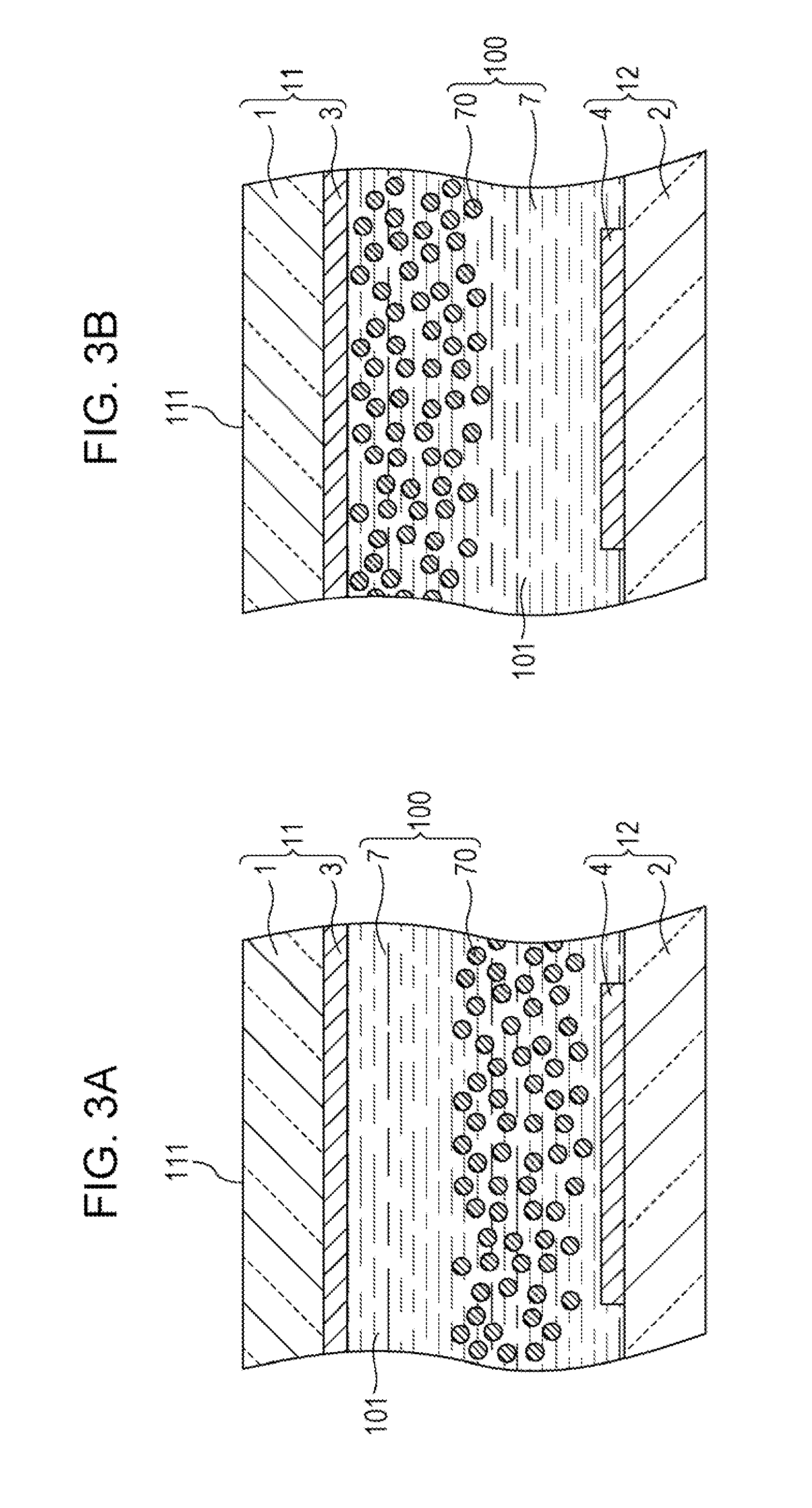

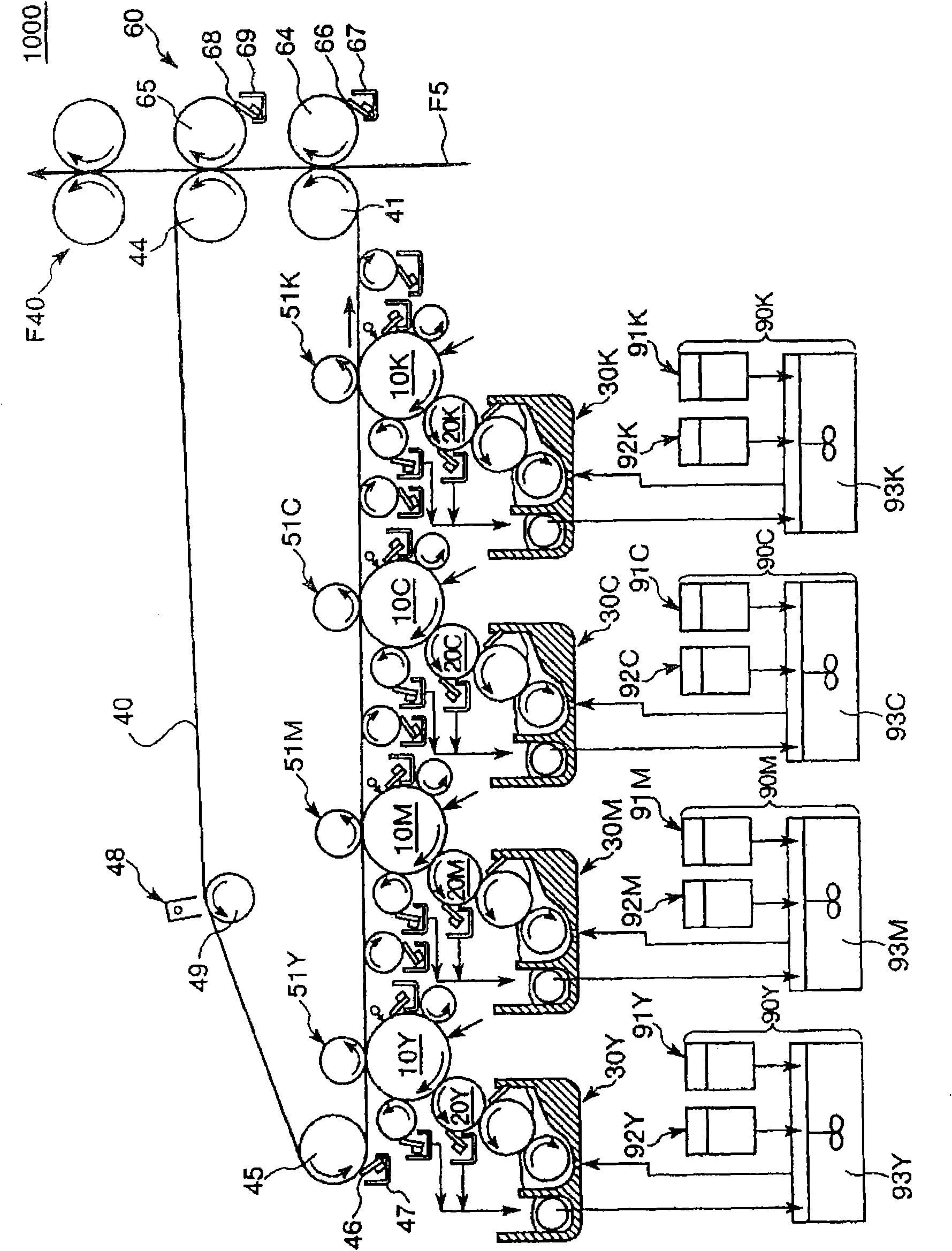

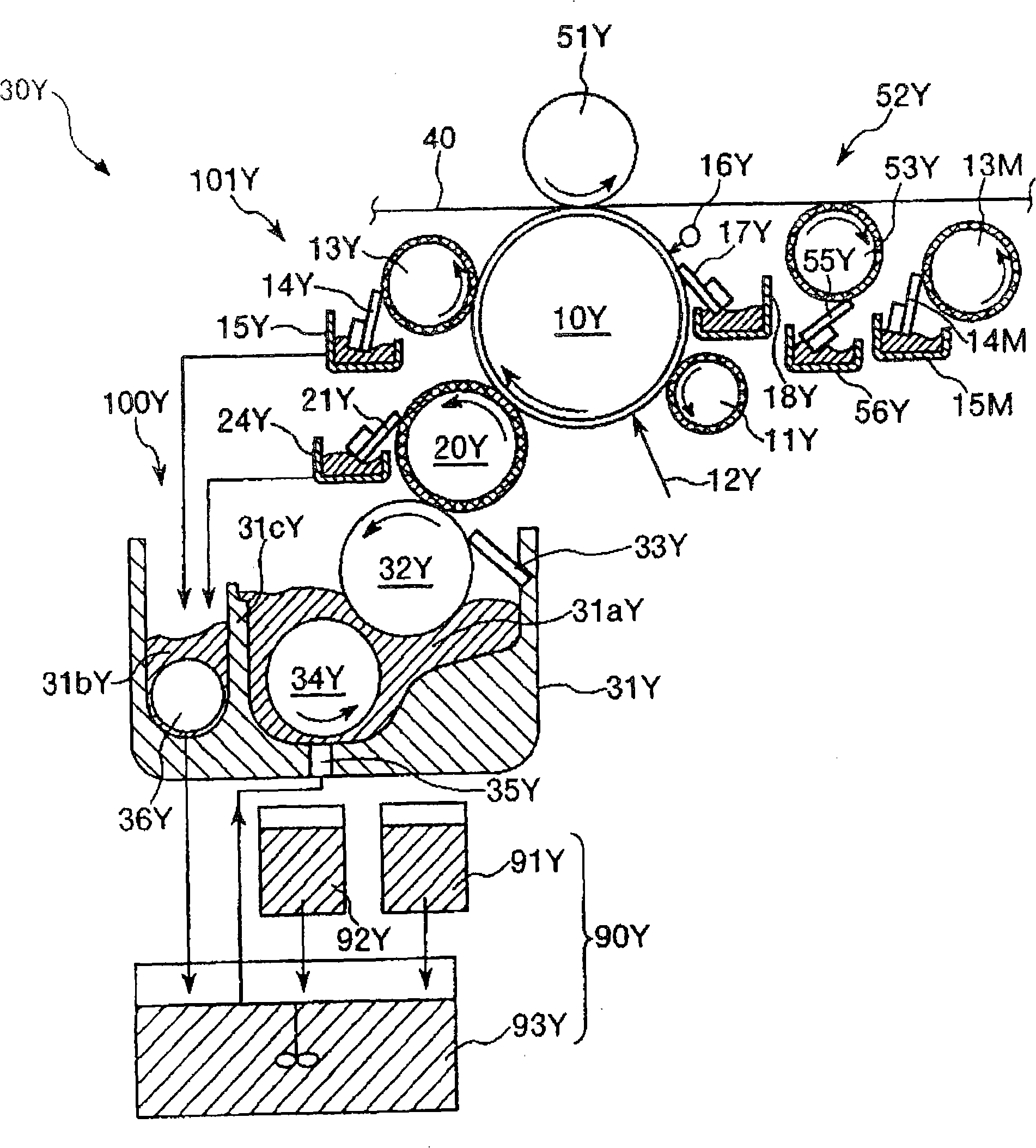

Multilayer type electrophotographic photoconductor and image forming apparatus

ActiveUS20070281227A1Improve image qualityLittle generationElectrographic process apparatusCorona dischargeElectrical conductorInter layer

The present invention is to provide a multilayer type electrophotographic photoconductor capable of stably obtaining a high image quality image over a long term by restraining the exposure memory and the photo memory, and an image forming apparatus comprising such a multilayer type electrophotographic photoconductor. A multilayer type electrophotographic photoconductor comprising a charge generating layer containing at least a charge generating agent on a base member directly or via an intermediate layer, and a charge transporting layer containing at least a charge transporting agent and a binder resin formed successively, wherein the light absorption degree at a 680 nm wavelength light beam in the photoconductive layer of the multilayer type electrophotographic photoconductor is of a value of 0.8 or less, and the light absorption degree at a 450 nm wavelength light beam is of a value of 1.0 or more, and an image forming apparatus comprising such a multilayer type electrophotographic photoconductor are provided.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

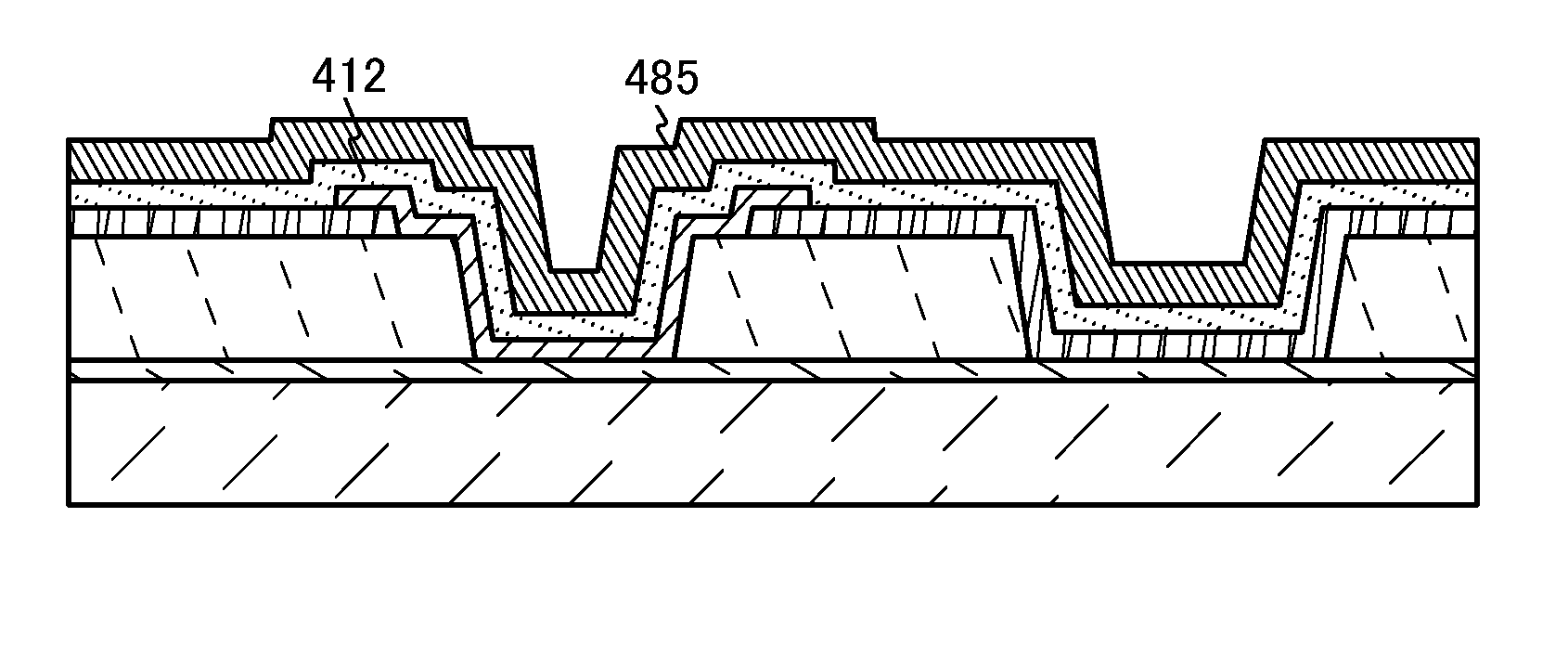

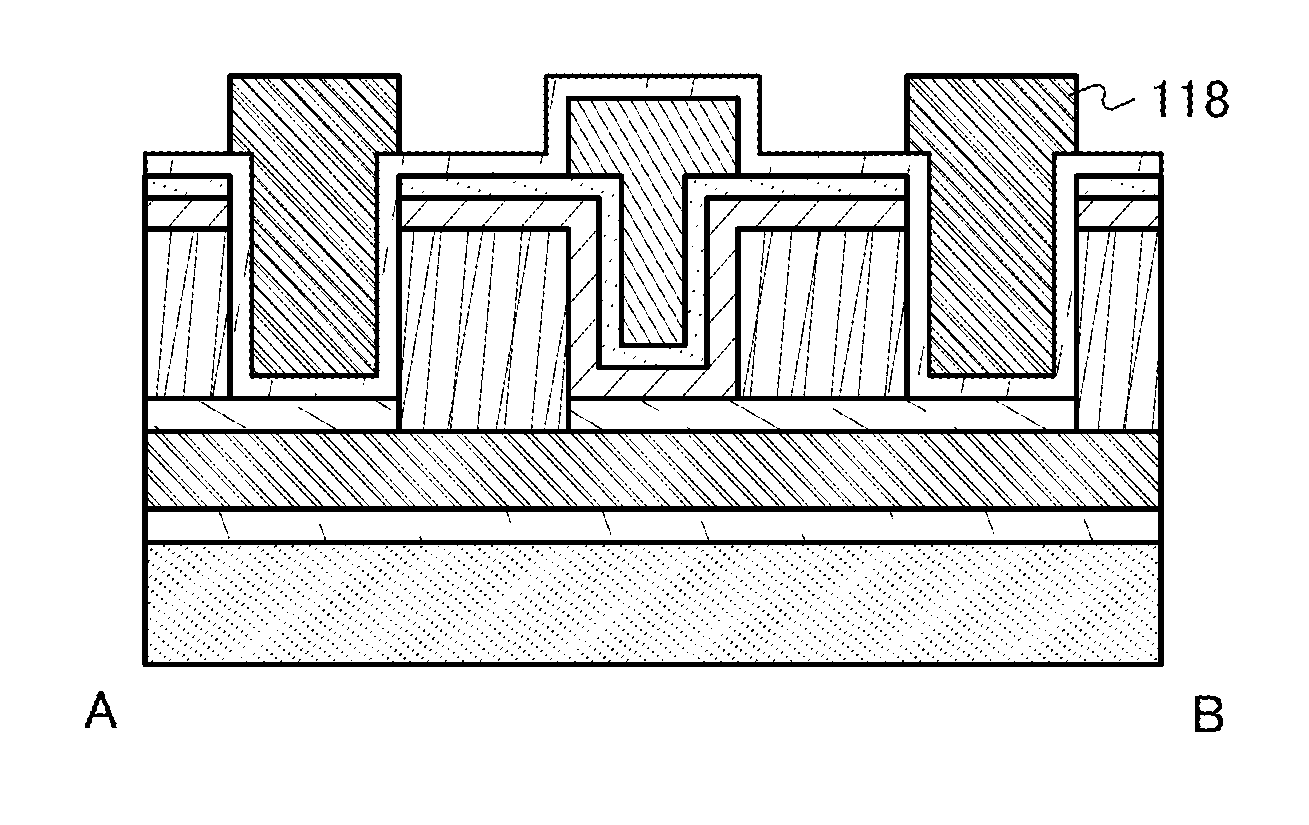

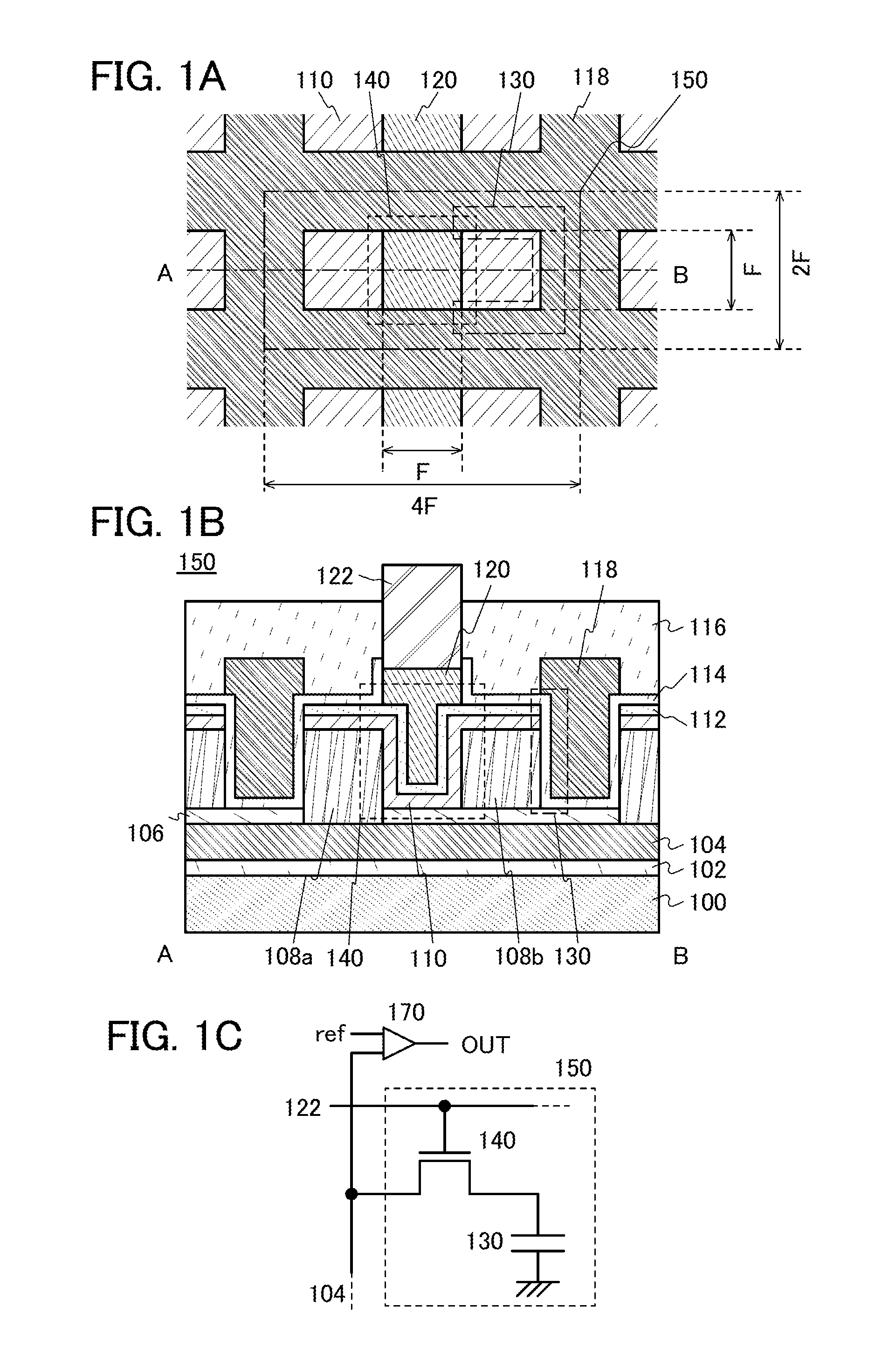

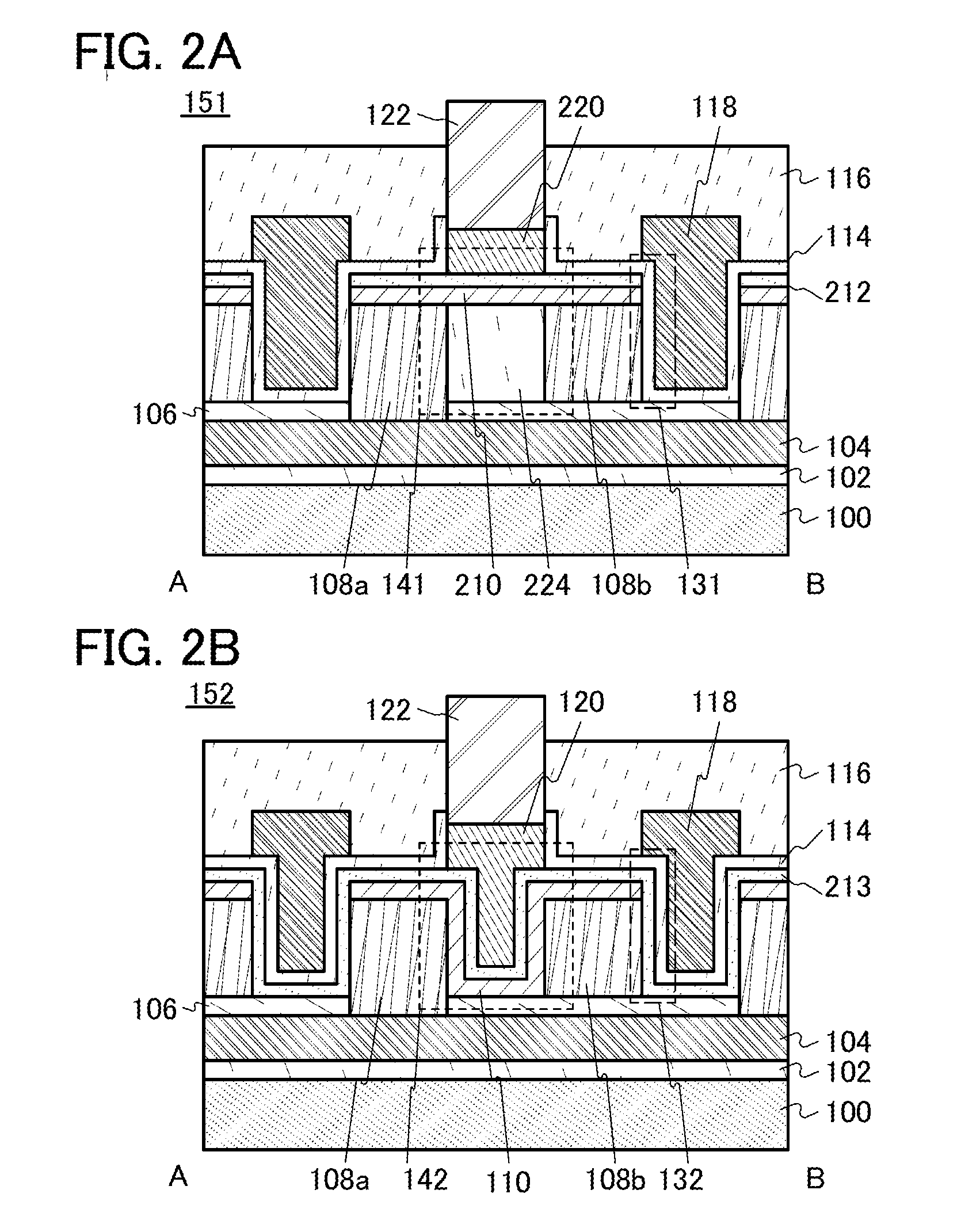

Semiconductor memory device and method for manufacturing the same

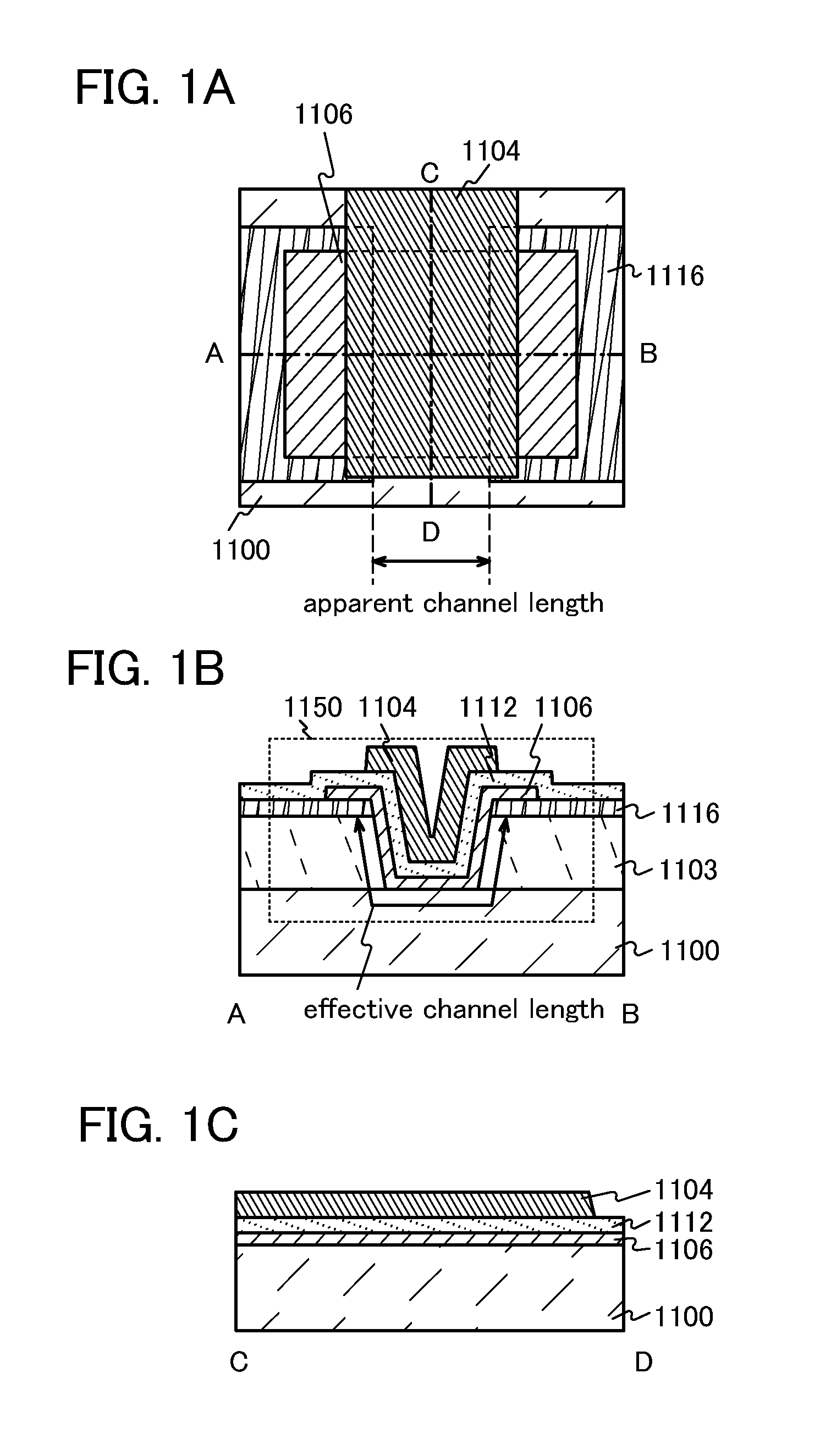

InactiveUS20120223310A1Total current dropReduce oxygen vacancyTransistorSolid-state devicesEngineeringCapacitor

A semiconductor memory device includes a transistor and a capacitor. The transistor includes: an insulating film in which a groove portion is provided; a pair of electrodes separated so that the groove portion is sandwiched therebetween; an oxide semiconductor film which is in contact with the pair of electrodes and side surfaces and a bottom surface of the groove portion and has a thickness value smaller than a depth value of the groove portion; a gate insulating film covering the oxide semiconductor film; and a gate electrode provided to overlap with the oxide semiconductor film with the gate insulating film positioned therebetween.

Owner:SEMICON ENERGY LAB CO LTD

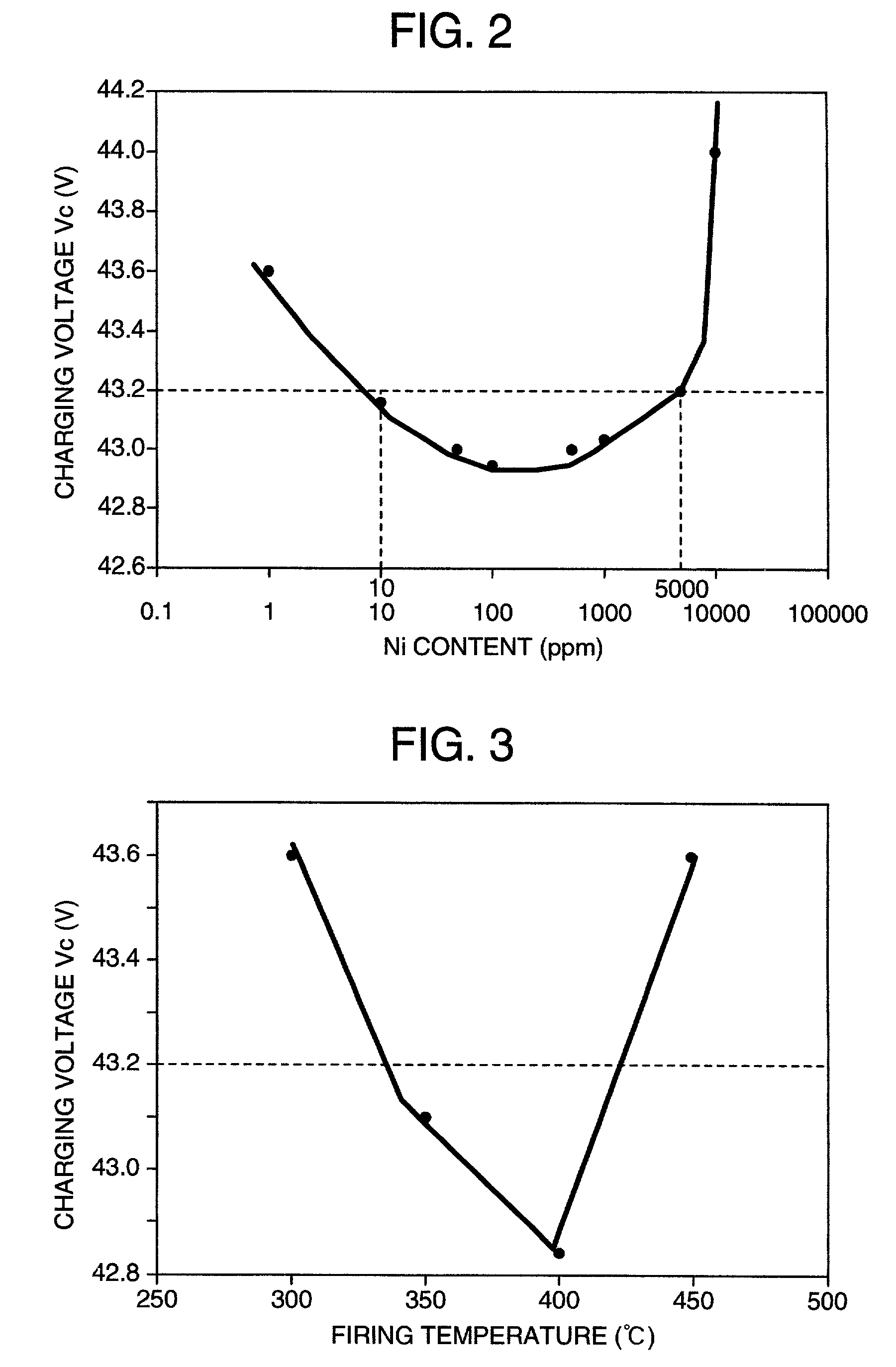

Lead-acid battery

InactiveUS7083876B2Improve charging characteristicsImprove conductivityLead-acid accumulatorsFinal product manufactureHybrid carSingle substance

A lead-acid battery superior in high-efficiency charging characteristic to conventional lead-acid batteries and a carbon material used in the lead-acid battery having excellent charge acceptability are disclosed. The lead-acid battery uses, as an additive to the anode active material, a simple substance and / or compound thereof, both having a catalysis for desulfurization or a catalyst for SOx oxidation by adding to, or loading on, a carbon material such as active carbon, carbon black, or the like. When the lead-acid battery with an anode containing carbon material is applied to electric cars, various hybrid cars, power storage systems, elevators, electromotive tools and power source systems such as uninterruptible power source, distributed power source and the like, all having high input and output requirements, stable control can be obtained.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

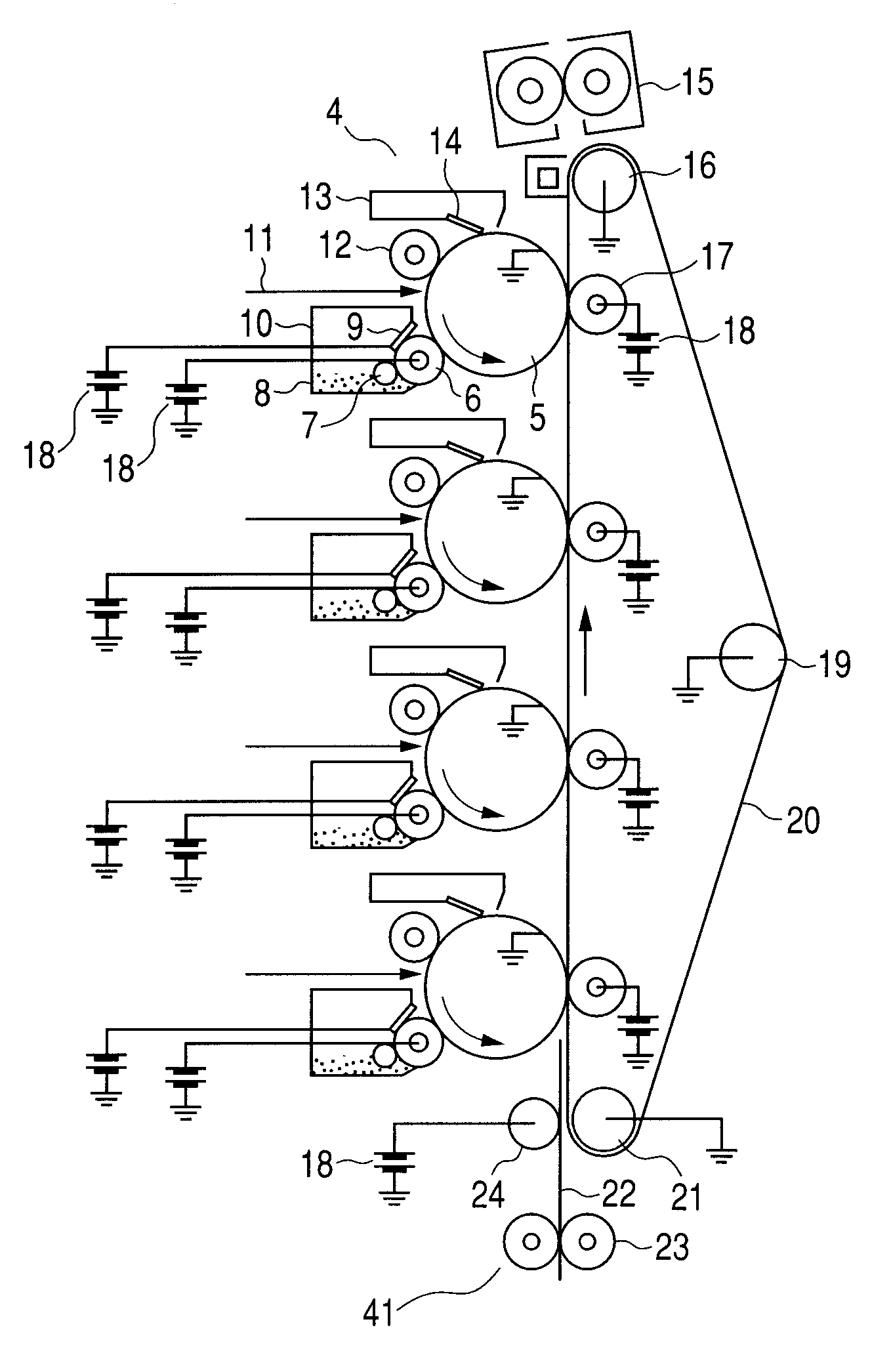

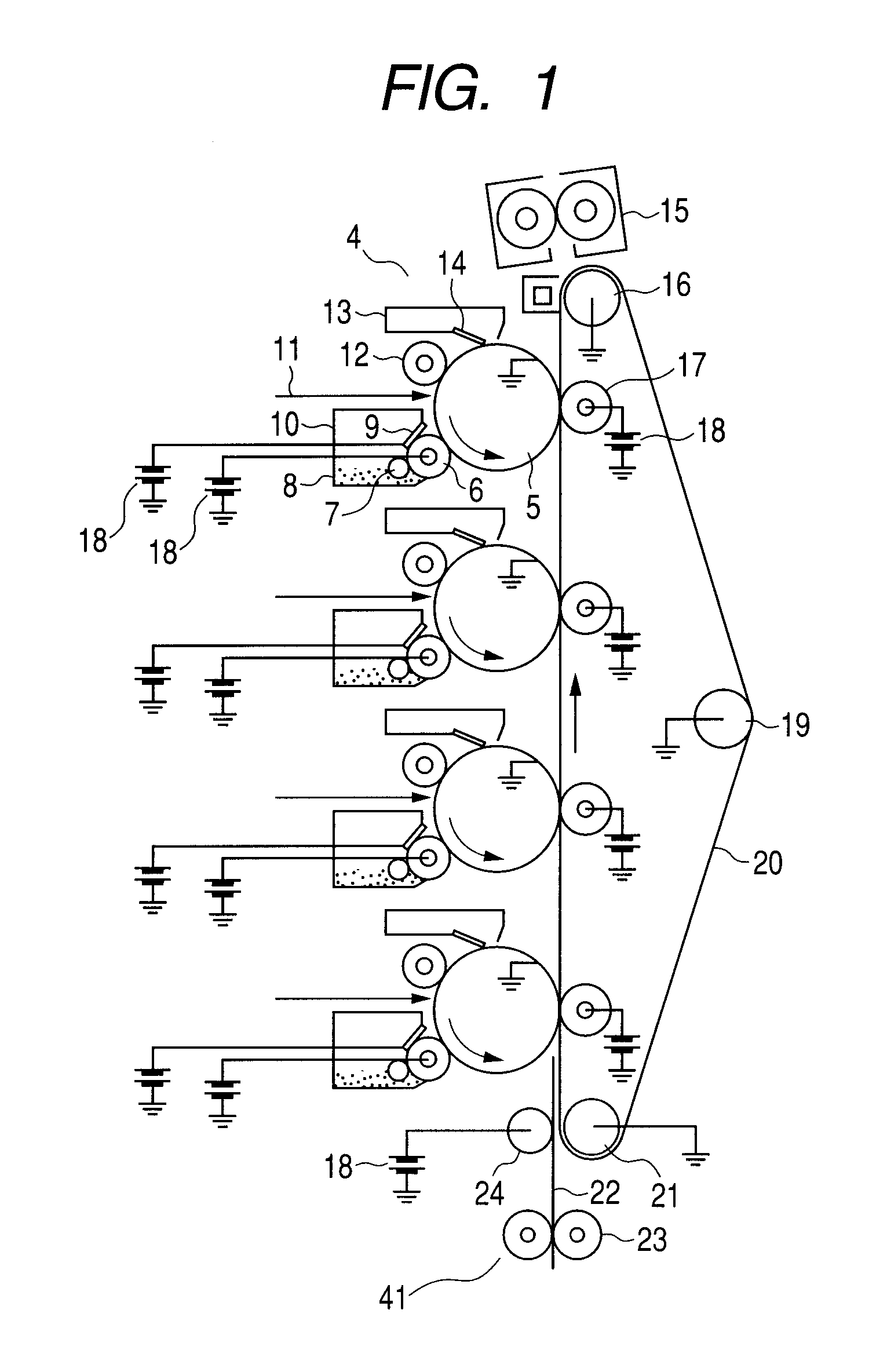

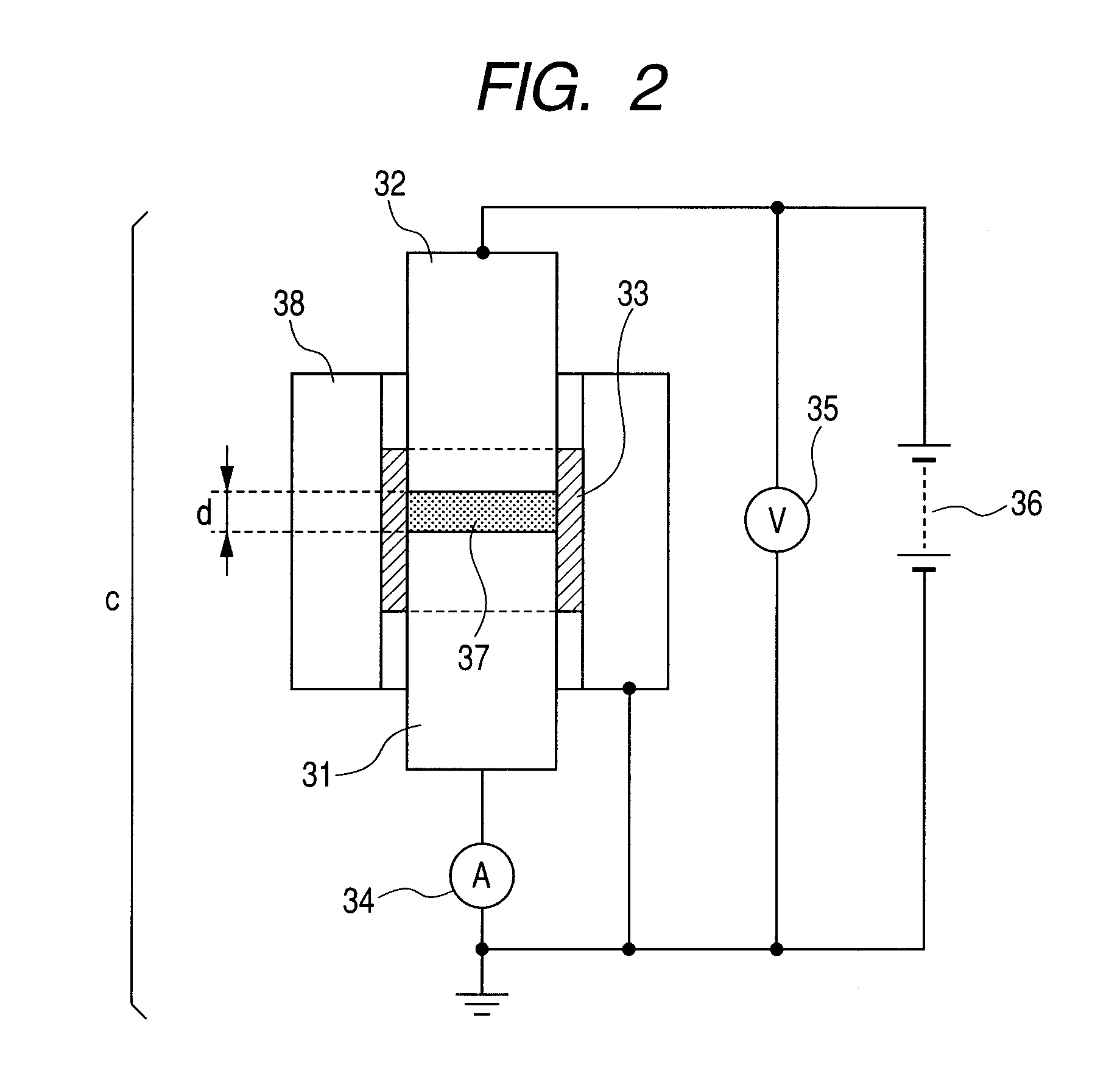

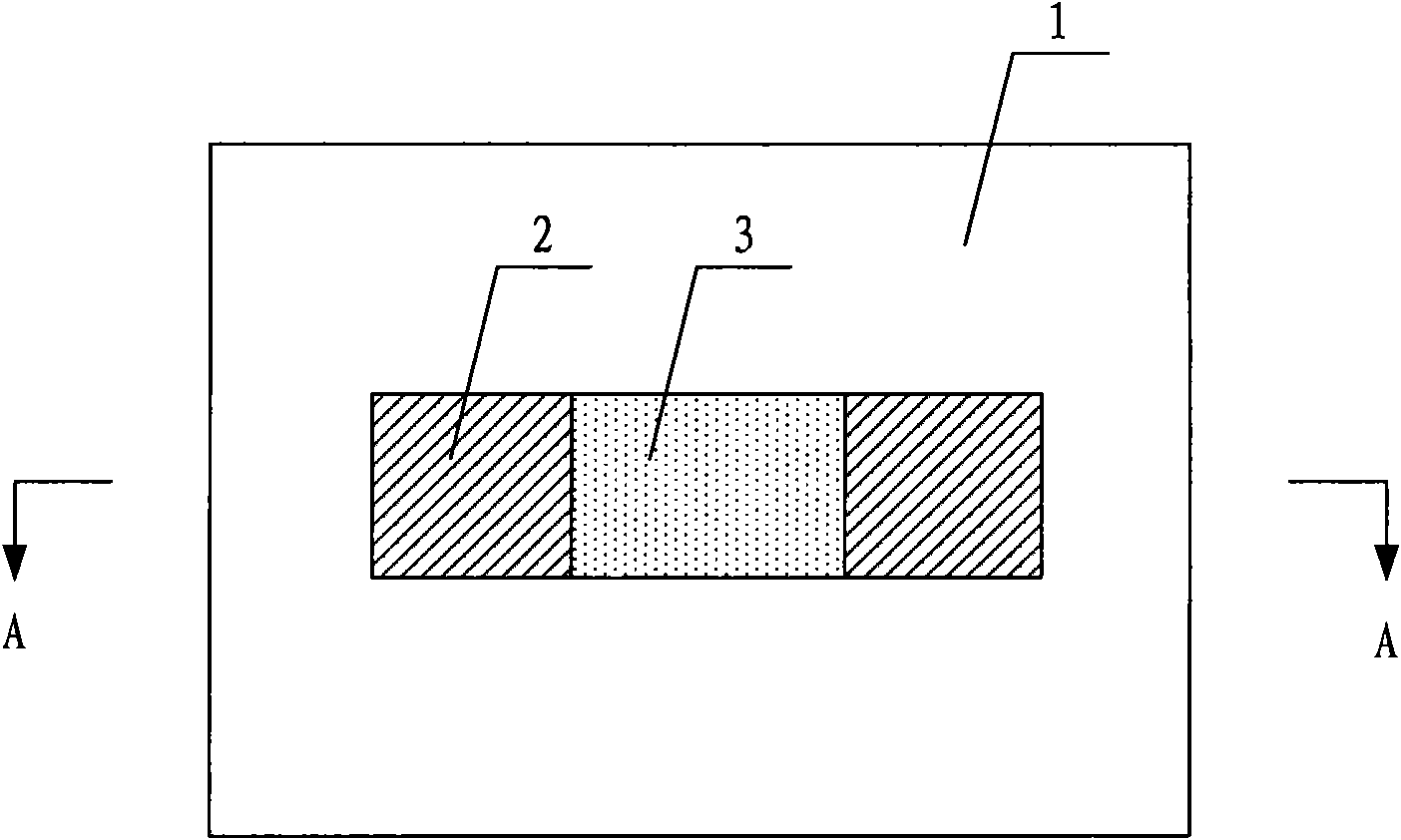

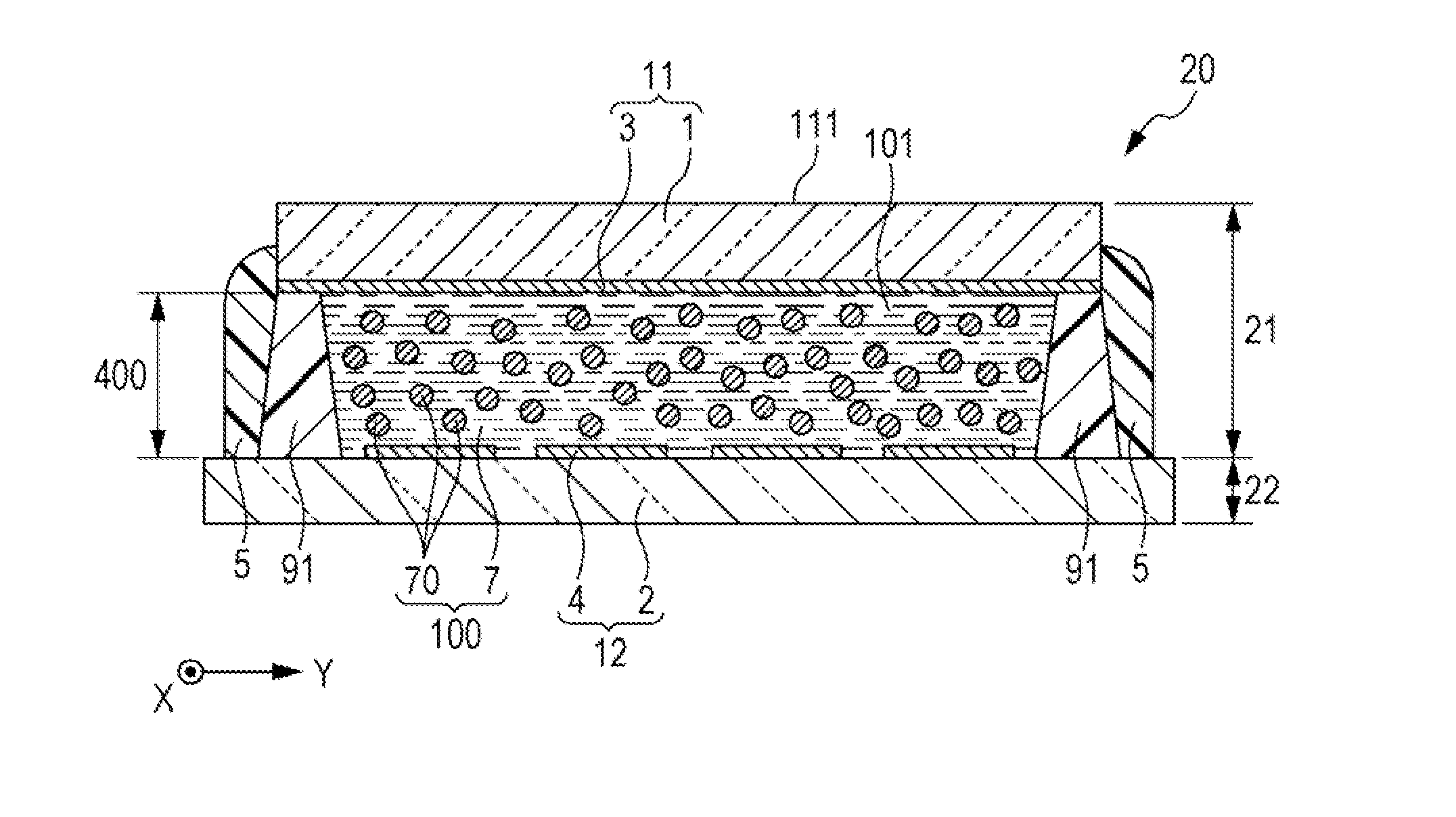

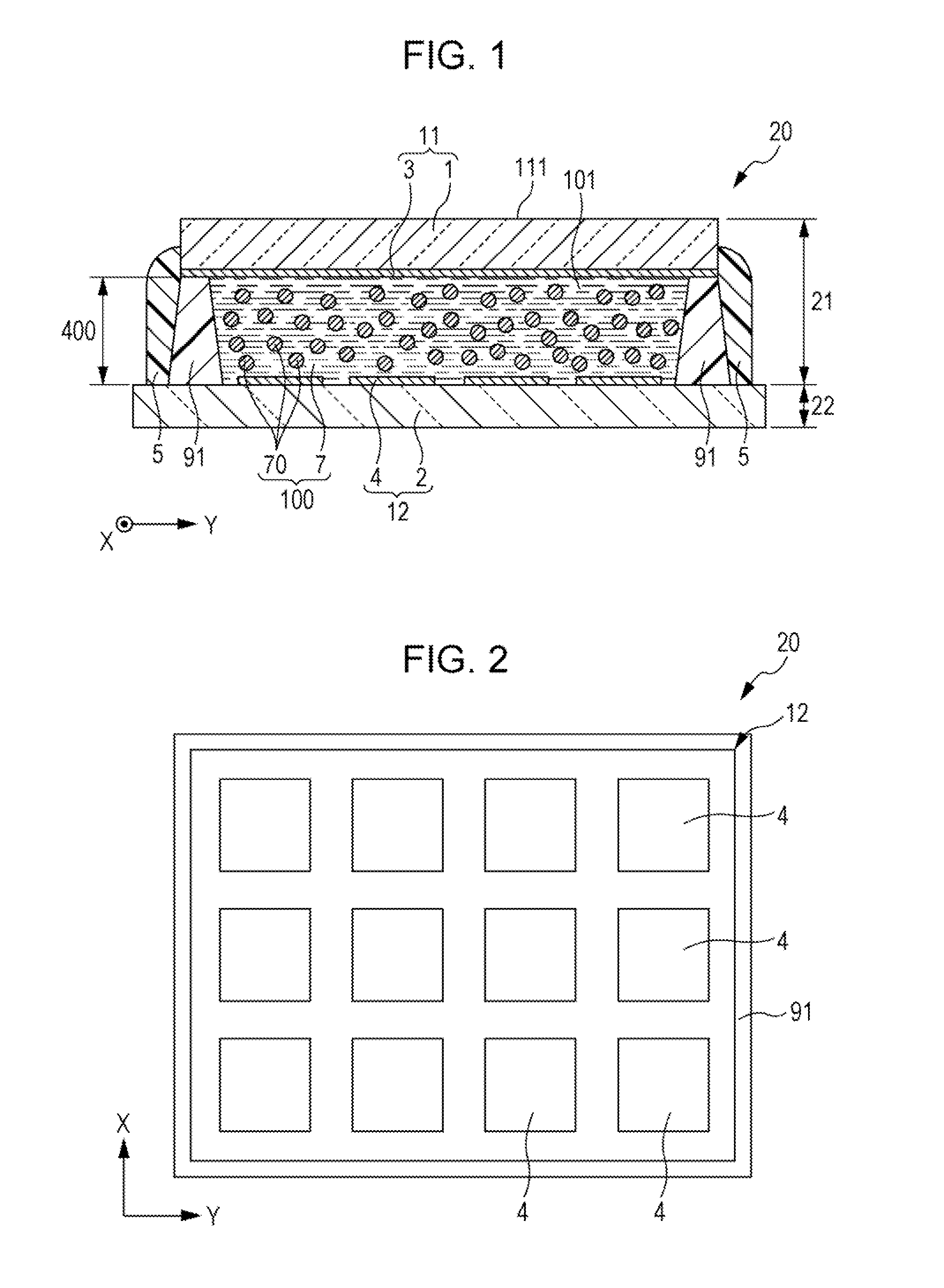

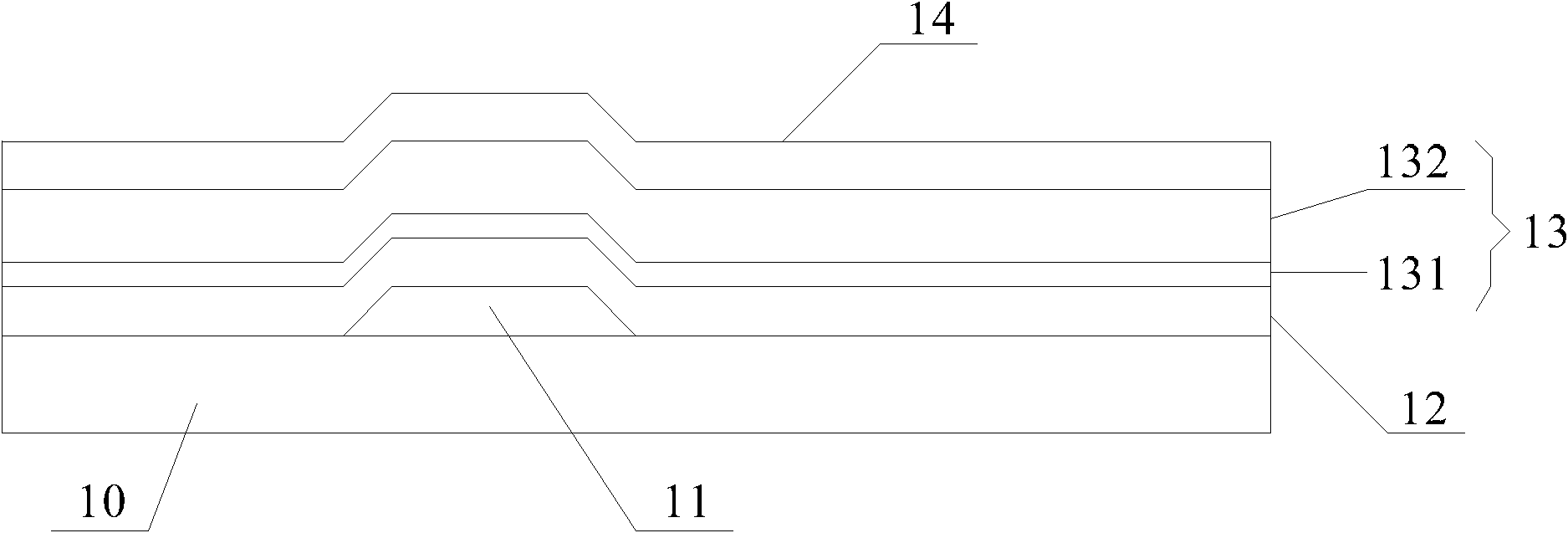

Apparatus and method of manufacturing electrodes, and battery

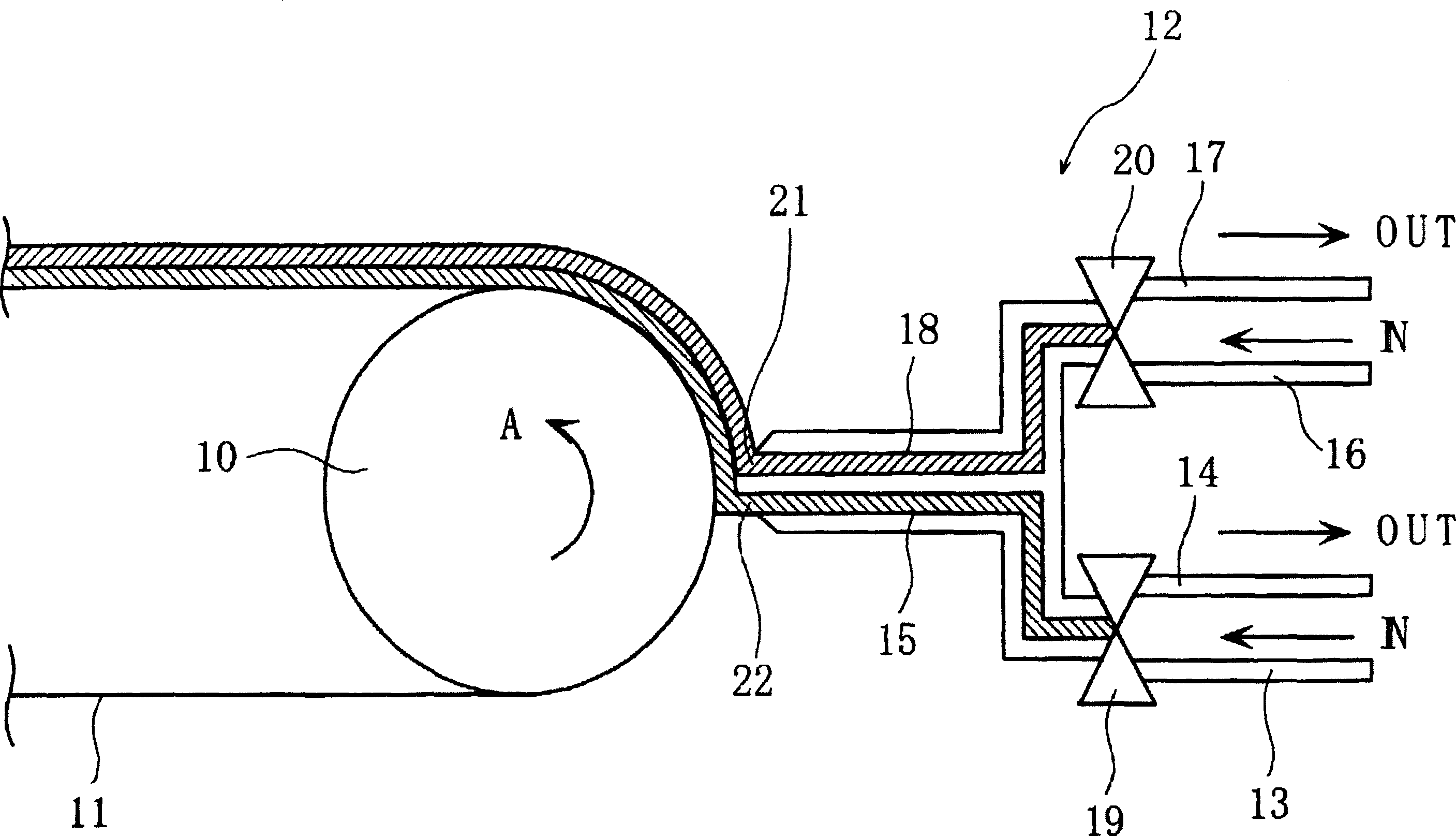

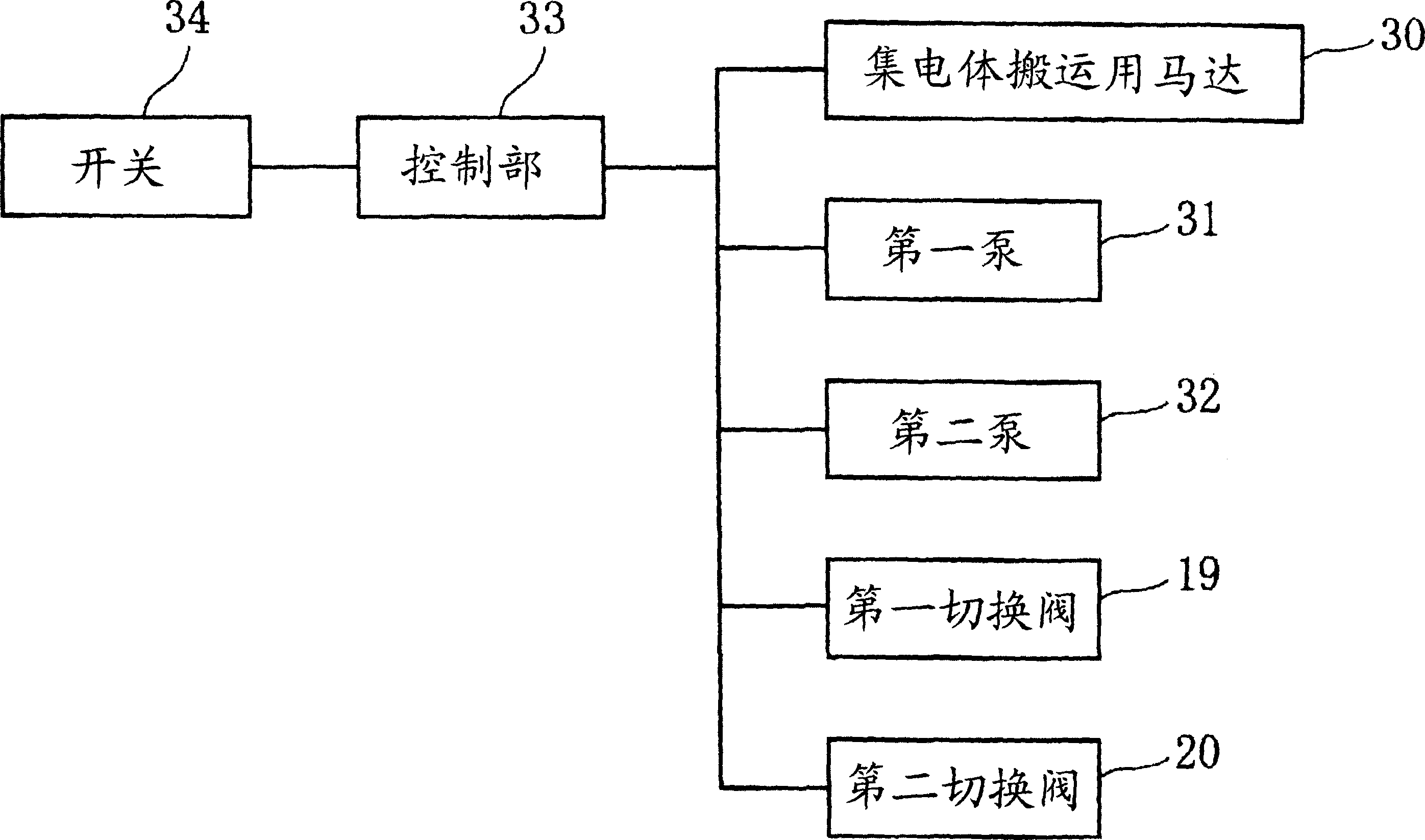

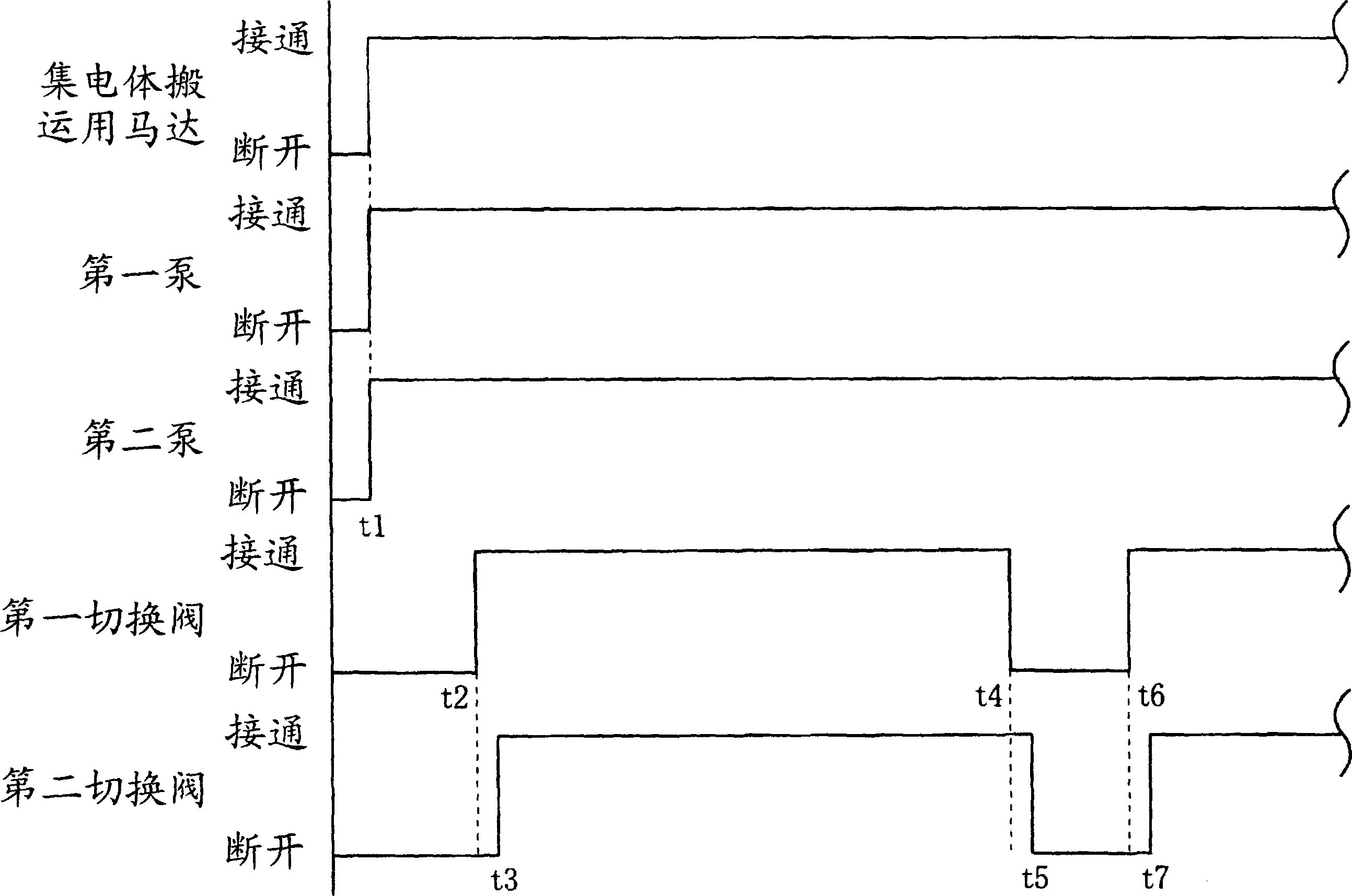

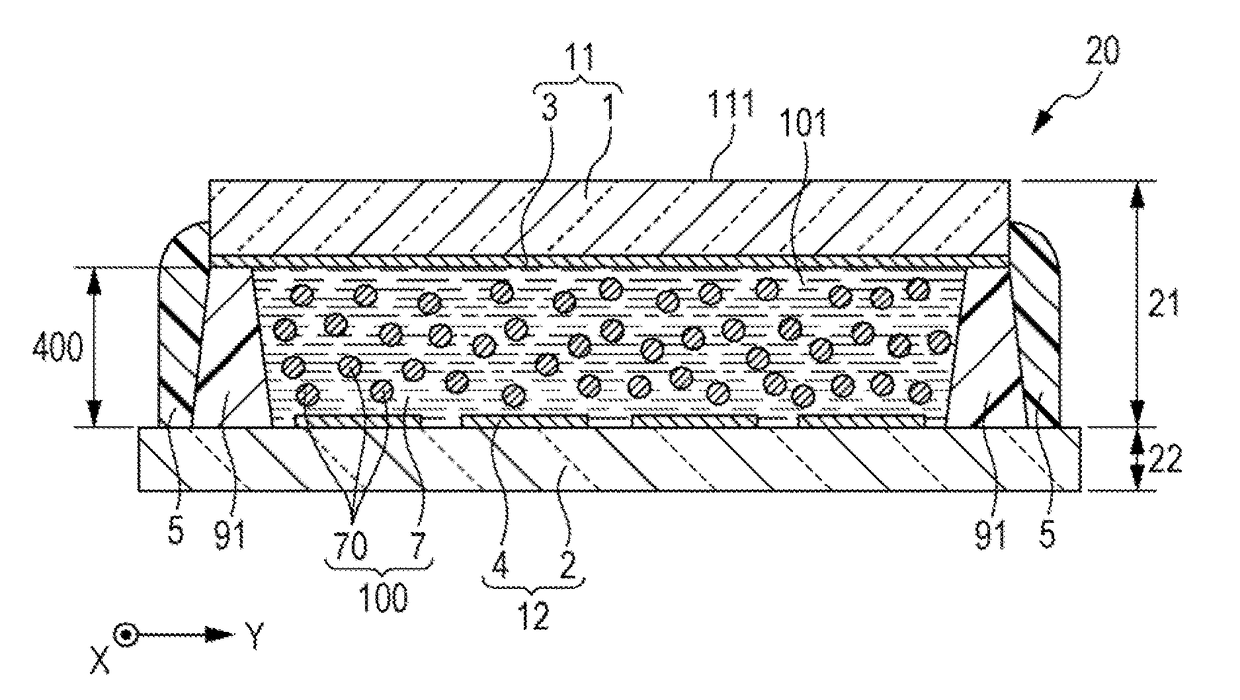

InactiveCN1905247APrevent deviationReduce performanceLiquid surface applicatorsActive material electrodesEngineeringSlurry

The object of the present invention is to provide an electrode manufacturing method, a manufacturing device, and a battery. It is possible to suppress the reduction in battery performance during normal charging and discharging due to the increase in the internal resistance of the electrode, and at the same time to improve the overcharge characteristics, and to suppress the occurrence of deviation between the active material layers and the adhesion between the active materials. reduce, or increase manufacturing costs. Two active material layers ( 2, 3) In the electrode manufacturing method, the above-mentioned plurality of active material slurries are sequentially laminated and coated on the surface of the current collector in a wet state, and then all the active material slurries are dried.

Owner:SANYO ELECTRIC CO LTD

Toner

ActiveUS8652725B2Improve charging characteristicsReduce in quantityDevelopersX-rayUltimate tensile strength

A toner having toner base particles each of which contains at least a binder resin and a colorant, and silica titania composite particles. The silica titania composite particles contain silica in an amount of from 55.0% by mass to 85.0% by mass; and, in a chart obtained by the measurement by X-ray diffraction of the silica titania composite particles and where, in respect of a peak having the highest diffraction intensity and a peak having the next-highest diffraction intensity among peaks present in the range of 2θ=24.0 to 29.0, the value of area of the peak on the lower-angle side is represented by Xa and the value of area of the peak on the higher-angle side is represented by Xb, the ratio of Xa / Xb is from 95 / 5 to 75 / 25.

Owner:CANON KK

Semiconductor memory device

InactiveUS20120261664A1Improve charging characteristicsReduce the refresh rateTransistorSolid-state devicesBit lineSemiconductor storage devices

A semiconductor memory device including a bit line, a word line, a transistor, and a capacitor is provided. The transistor includes source and drain electrodes; an oxide semiconductor film in contact with at least both top surfaces of the source and drain electrodes; a gate insulating film in contact with at least a top surface of the oxide semiconductor film; a gate electrode which overlaps with the oxide semiconductor film with the gate insulating film provided therebetween; and an insulating film covering the source and drain electrodes, the gate insulating film, and the gate electrode. The transistor is provided in a mesh of a netlike conductive film when seen from the above. Here, the drain electrode and the netlike conductive film serve as one and the other of a pair of capacitor electrodes of the capacitor. A dielectric film of the capacitor includes at least the insulating film.

Owner:SEMICON ENERGY LAB CO LTD

Toner compositions

ActiveUS7300734B2Prevents toner clouding and dirtImprove charging characteristicsDevelopersCharge controlTitanium oxide

A toner composition comprising a binder, colorant, and a charge control surface additive mixture comprising a mixture of a first titanium dioxide possessing a first conductivity and a second titanium dioxide possessing a second conductivity and which second conductivity is dissimilar than the first conductivity; wherein the mixture of the first titanium dioxide and the second titanium dioxide is selected in a ratio sufficient to impart a selected triboelectric charging characteristic to the toner composition.

Owner:XEROX CORP

Solid electrolyte material including sulfide layer and oxide layer, and battery including the solid electrolyte material

ActiveUS20180316057A1Reduce generationLow efficiencySolid electrolytesCell electrodesSulfurPhysical chemistry

A solid electrolyte material includes: a sulfide layer containing lithium atoms and sulfur atoms; and an oxide layer covering the sulfide layer, the oxide layer containing lithium atoms and oxygen atoms. The solid electrolyte material satisfies 0.51≤x and x / y≤1.53, where x is a first ratio of the number of the oxygen atoms to the number of the lithium atoms at a depth 4 nm of the solid electrolyte material from the surface of the oxide layer; and y is a second ratio of the number of the oxygen atoms to the number of the lithium atoms at a depth 100 nm of the solid electrolyte material from the surface of the oxide layer.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Mask and production method thereof

ActiveCN101650526ALarge inclinationDecrease the inclinationPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringPhotoresist

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

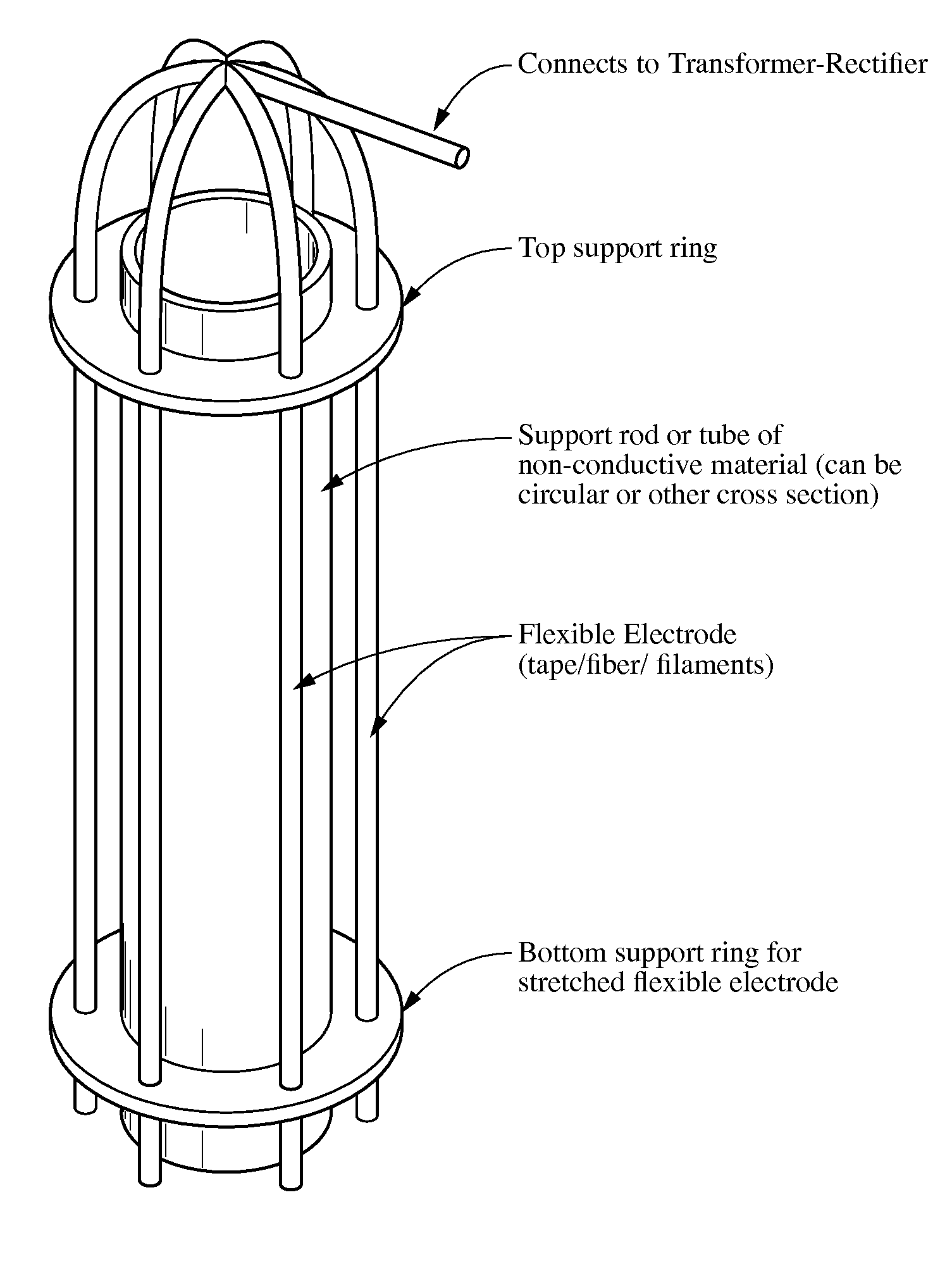

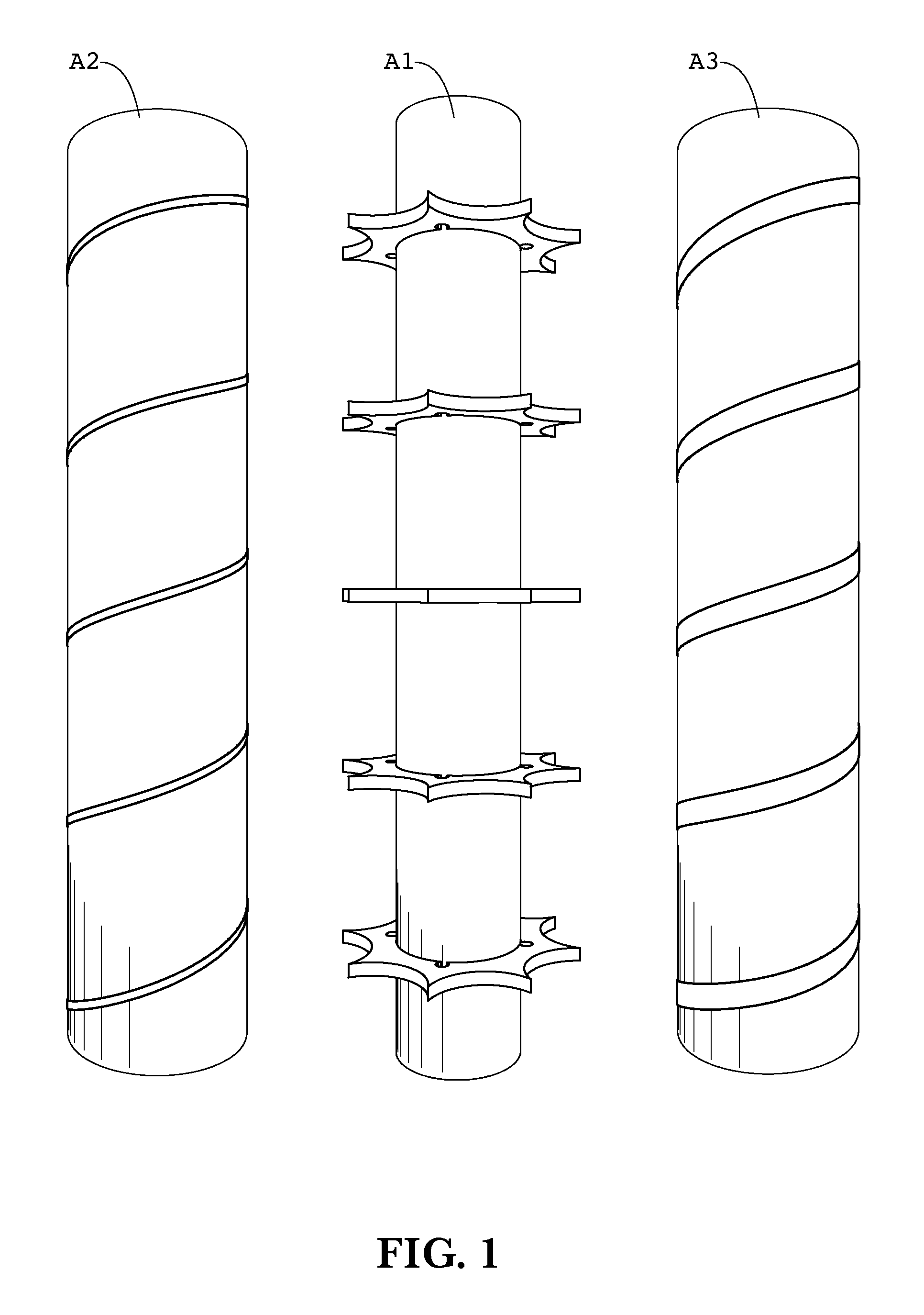

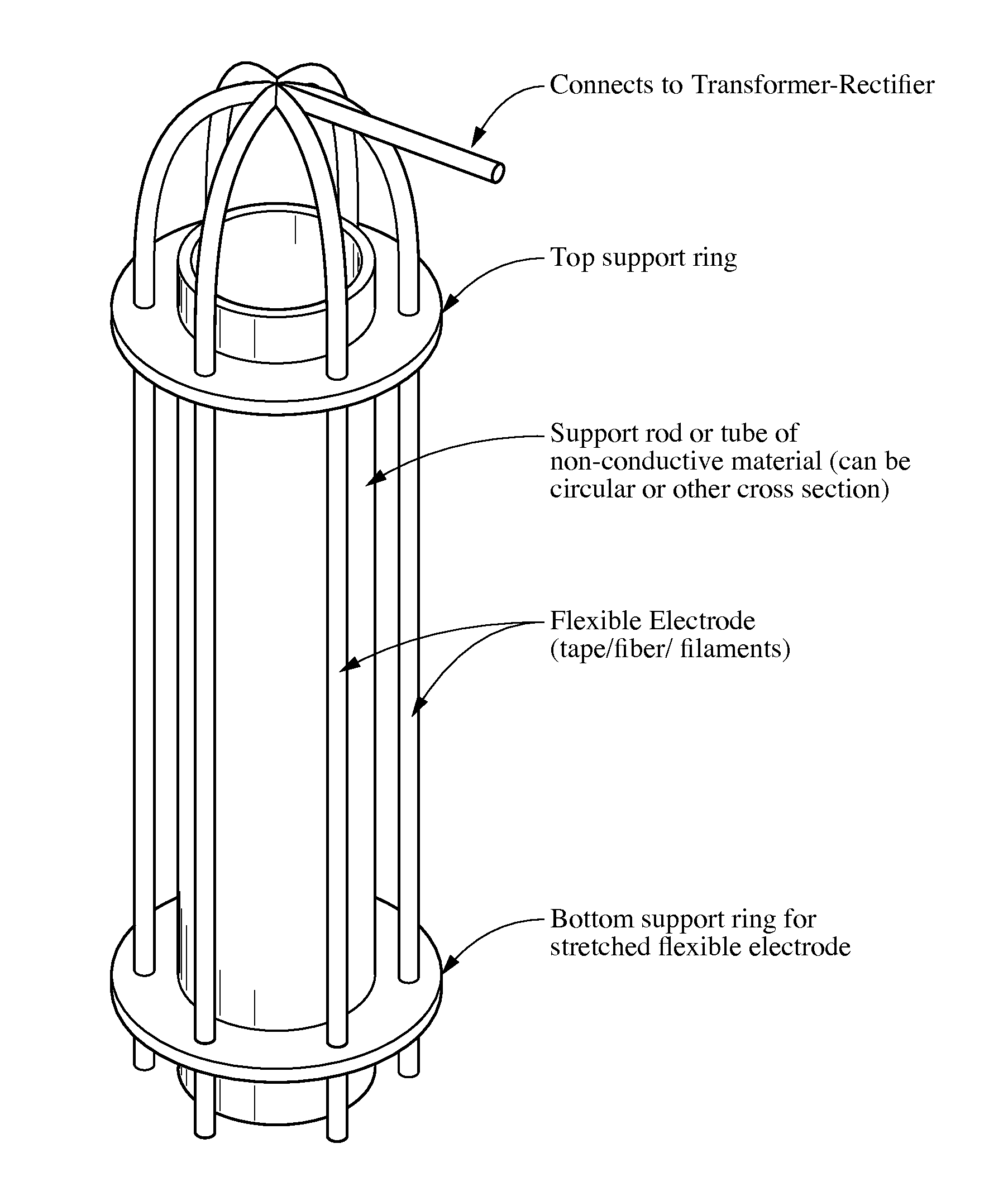

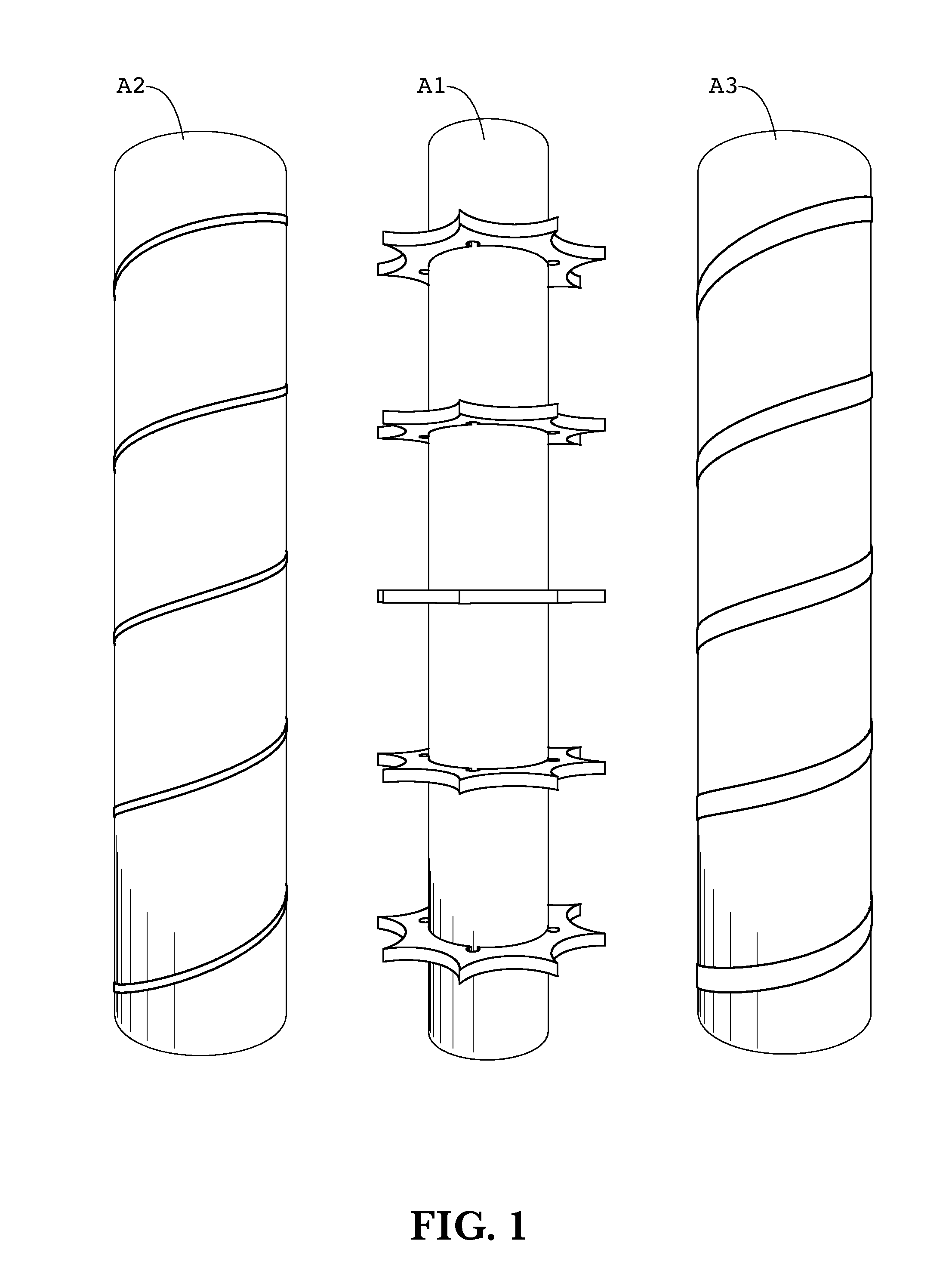

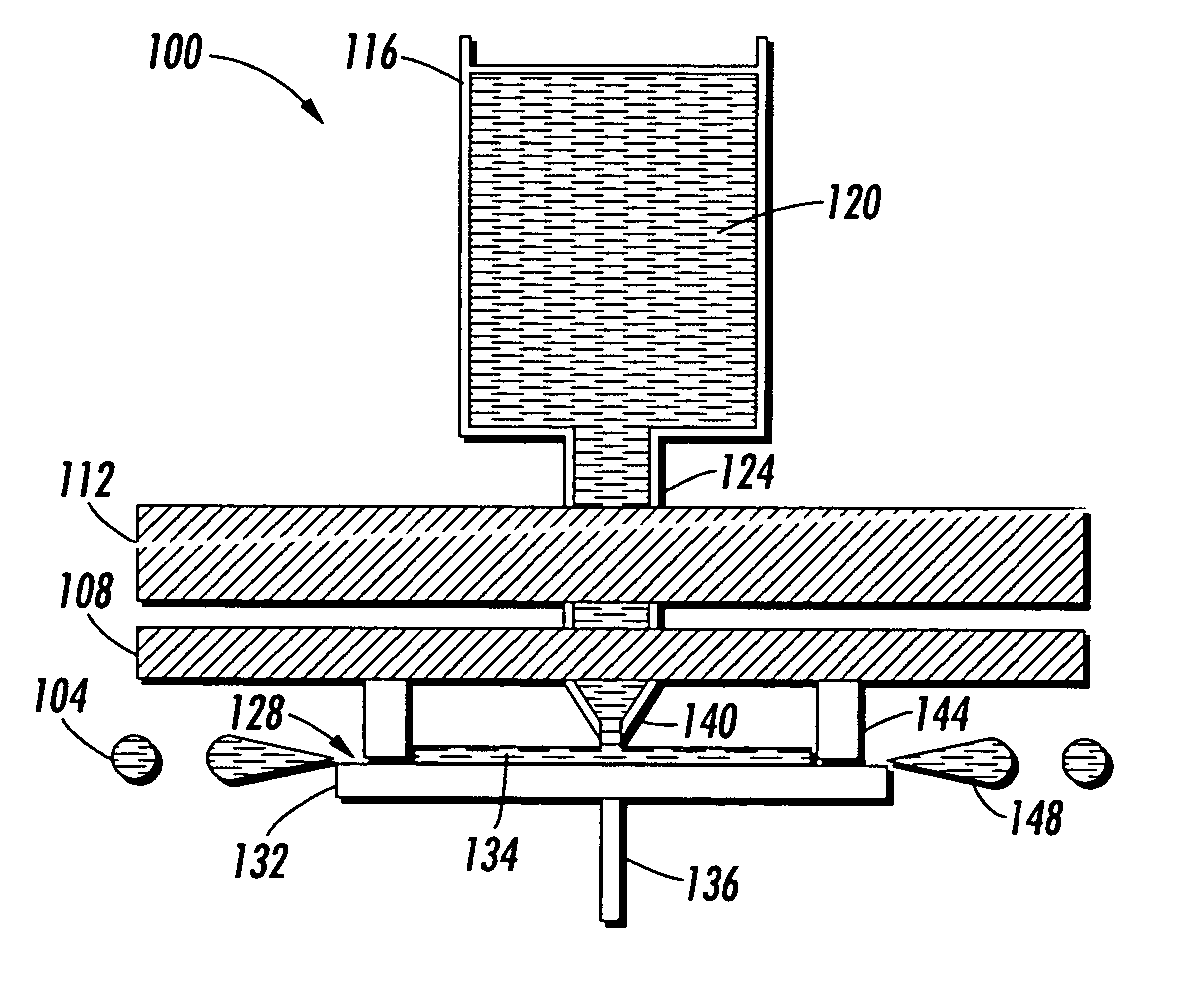

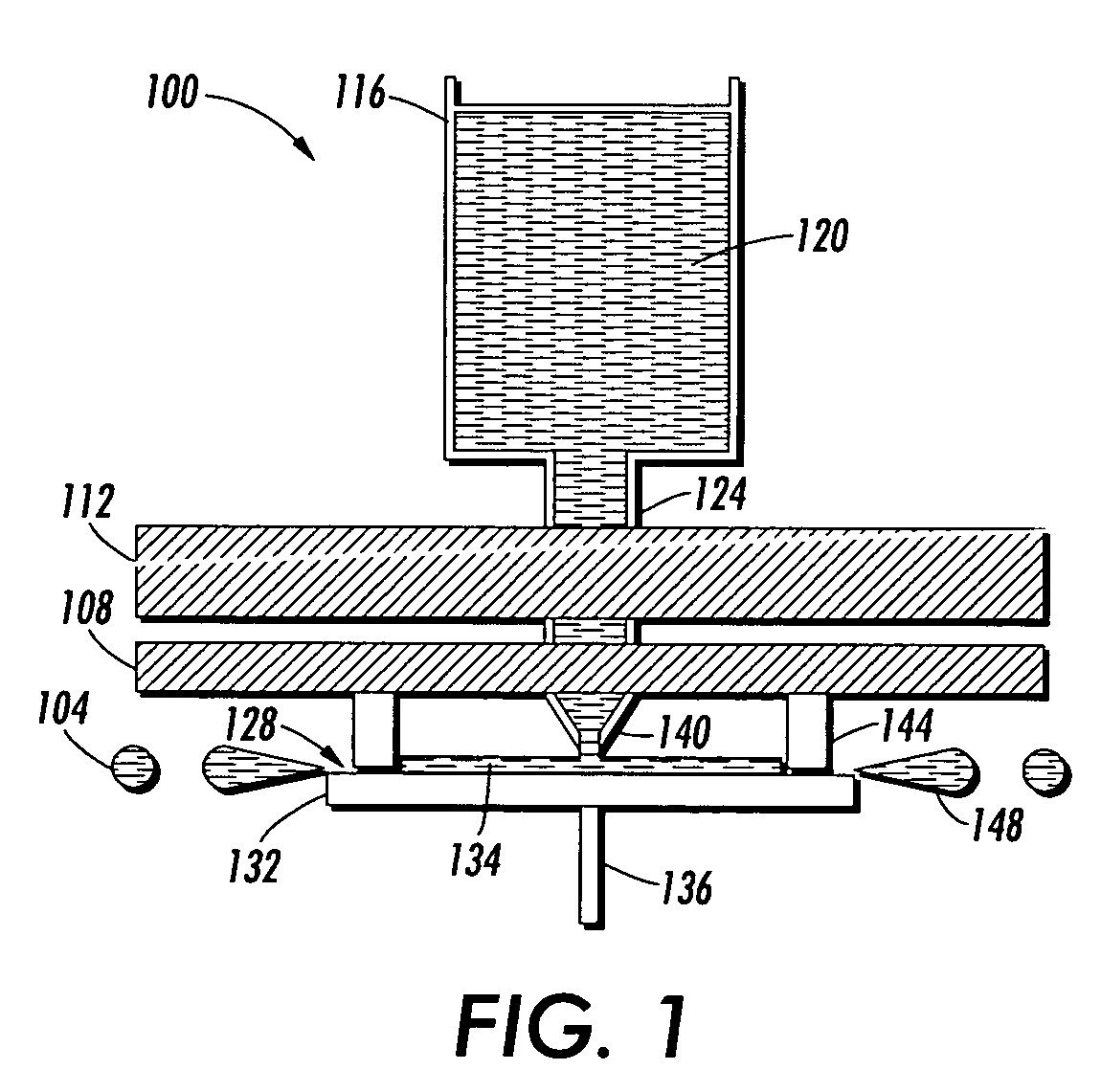

Carbon fiber composite discharge electrode

A discharge electrode using carbon fibers, nanofibers and / or nanotubes to generate the corona discharge. The invention contemplates carbon fiber electrodes with or without a polymer matrix to form a composite, and a supporting configuration in which the fibers are wrapped helically around a supporting rod that extends along the length of the electrode. Another supporting configuration includes the fibers stretched across the gas flow path. Yet another supporting configuration includes mounting the fibers along the length of the support rod substantially parallel to the rod.

Owner:OHIO UNIV

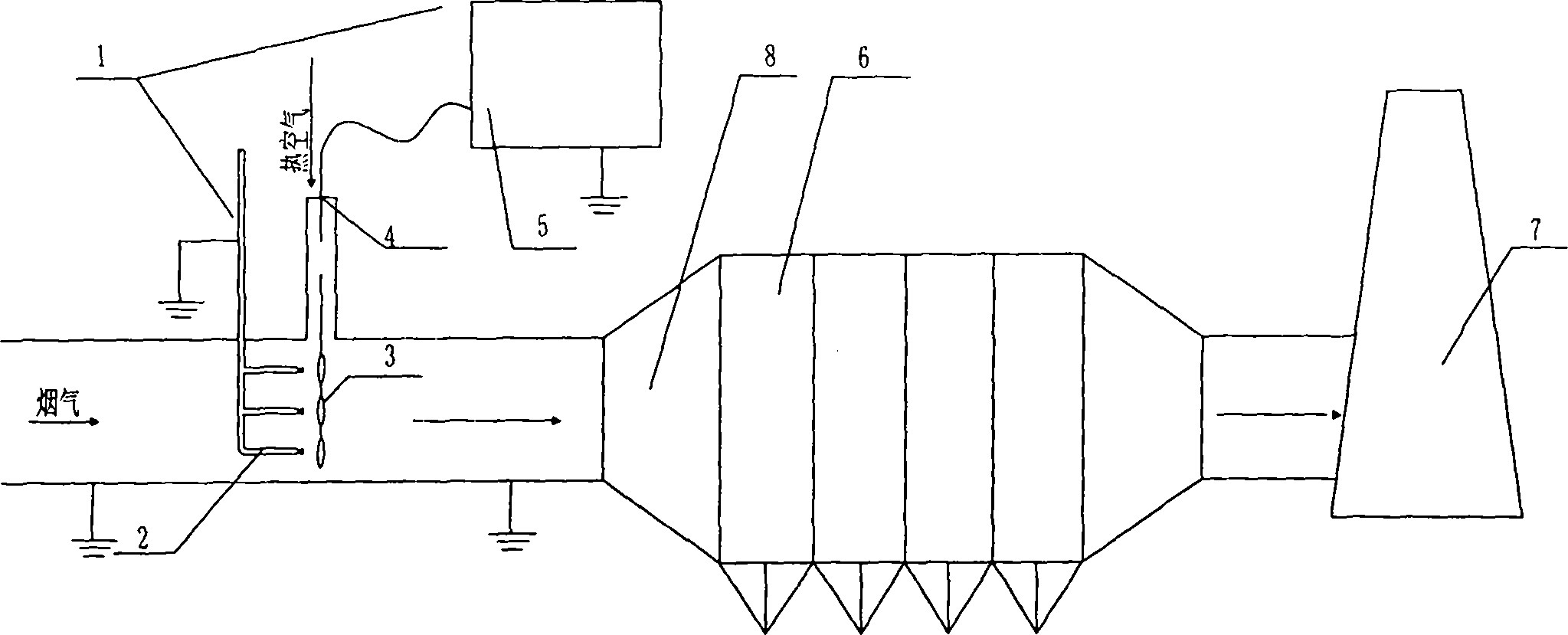

Heat pipe and spray charging and particle modifying coupled synergistic electrostatic dust removing system assisting in desulfurization waste water treatment

ActiveCN108387124AEfficient purificationEasy to handleIndirect heat exchangersElectrostatic separation detailsElectricityCorona ring

The invention provides a heat pipe and a spray charging and particle modifying coupled synergistic electrostatic dust removing system assisting in desulfurization waste water treatment. The system comprises a water charging device and an electrostatic dust remover. The water charging device is installed on a flue on the front portion of an inlet of the electrostatic dust remover. The spray charging device is connected with a desulfurization waste water temporary storage pool and provided with an atomizing nozzle. A corona ring is installed at the downstream of the atomizing nozzle and connected with a high-voltage power supply. The novel heat pipe structure is provided, meanwhile, mixed spray of the desulfurization waste water and a particle modifier is obtained through the dual-fluid atomizing nozzle, quick charging is achieved through a charging ring, the desulfurization waste water can be effectively treated, fine particles can be fully agglomerated, and the particle removal efficiency is improved; and meanwhile, the spray charging device can be installed on the flue on the front portion of the inlet of the electrostatic dust remover, so that flexibility and convenience are achieved.

Owner:SHANDONG UNIV

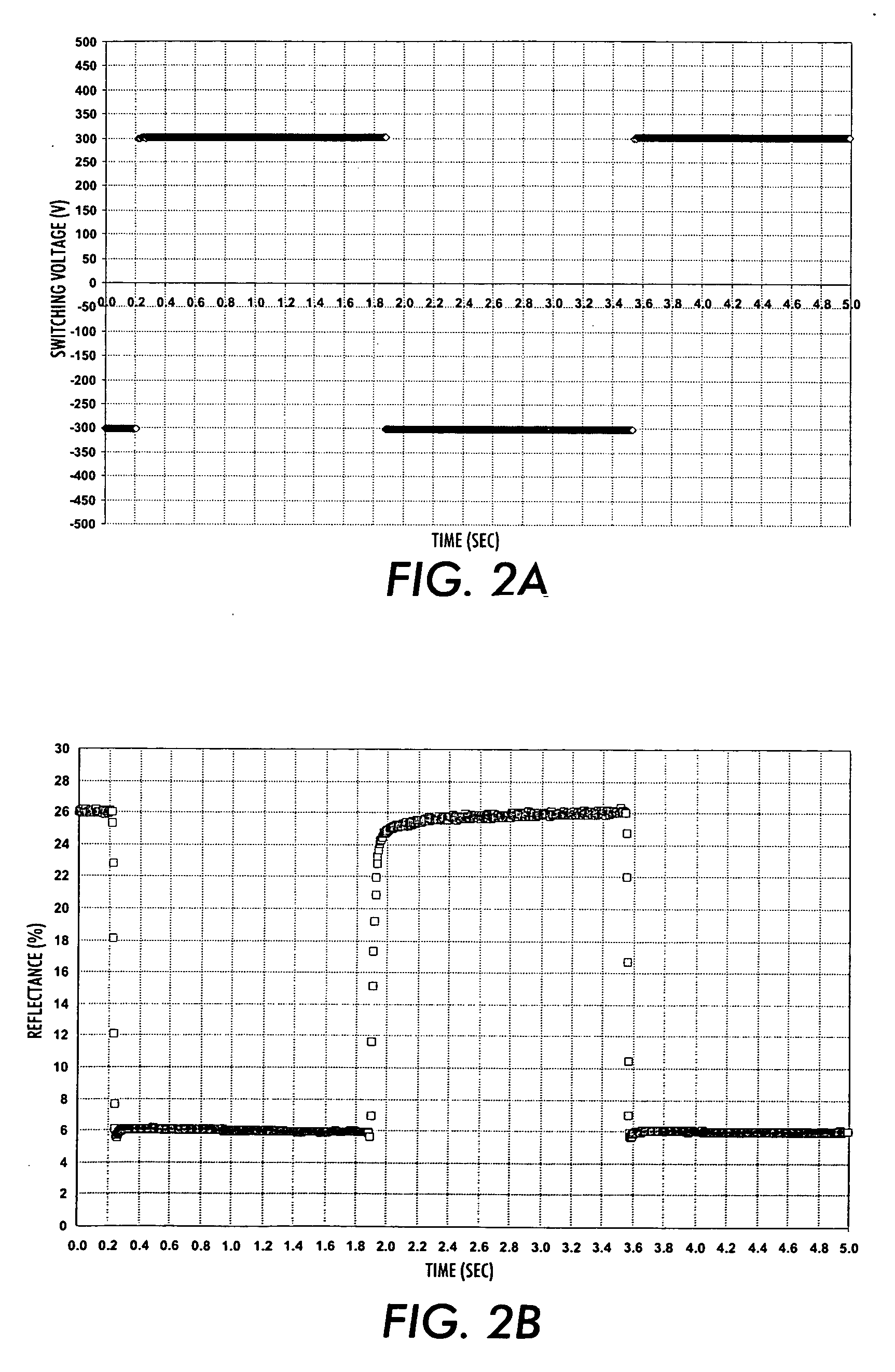

Electrophoretic particles, electrophoretic dispersion liquid, display sheet, display device, and electronic equipment

ActiveUS20140376081A1Reliable equipmentDispersibility mainlyElectrographic processes using photoelectrophoresisElectrographic process apparatusElectrophoresisOrganic group

Electrophoretic particle include a core particle; a siloxane-based compound that is bonded to a surface of the core particle and contains a connection structure in which a plurality of siloxane bonds are serially connected to each other; and a polarizing group that is an organic group bonded to the surface of the core particle, contains a main skeleton and a substituent bonded to the main skeleton, and has unevenly distributed electrons on the particle side of the main skeleton or the opposing side thereof.

Owner:E INK CORPORATION

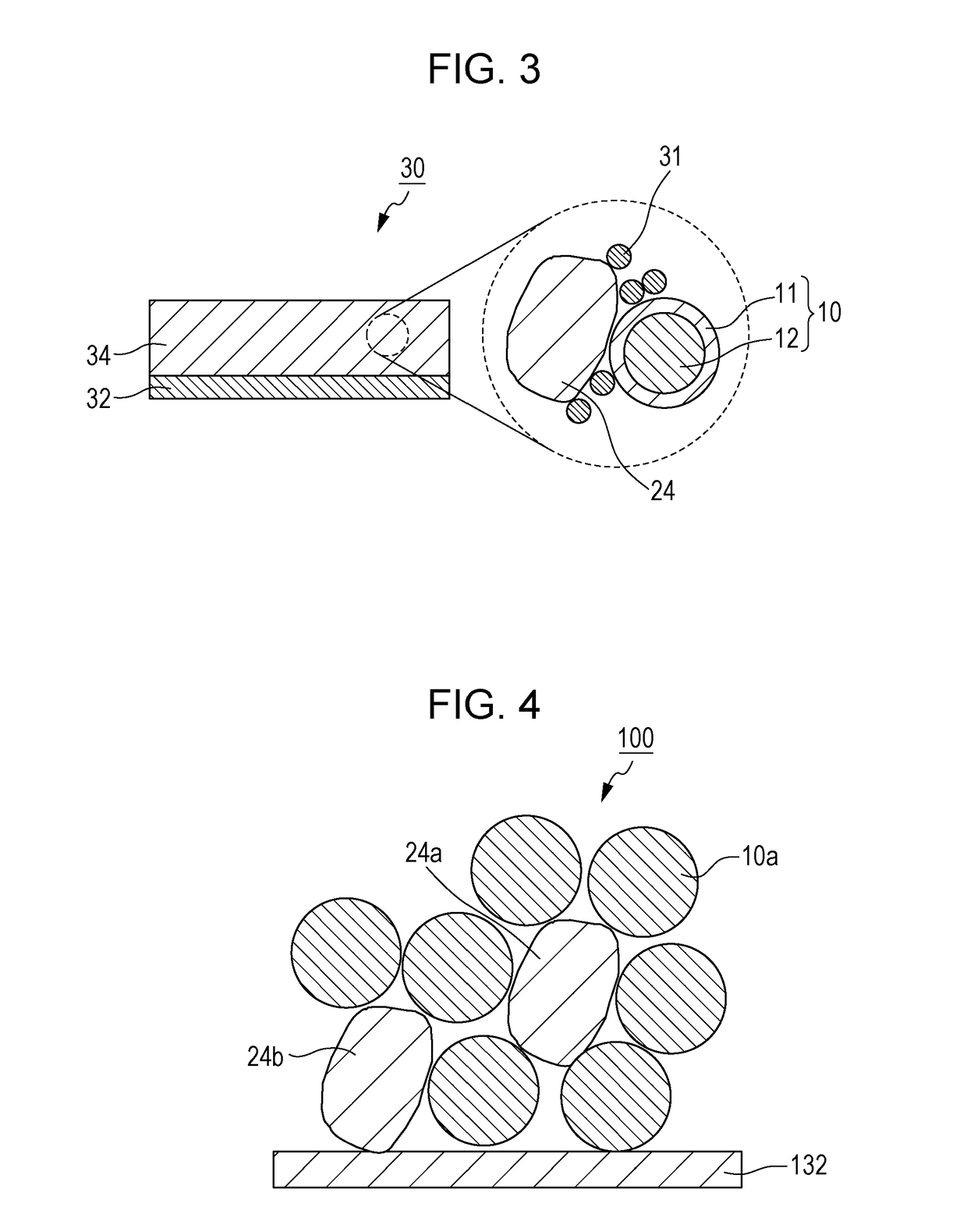

Carbon fiber composite discharge electrode

ActiveUS20120227588A1Low costHigh strengthMaterial nanotechnologyElectrode carrying meansFiberNanofiber

A discharge electrode using carbon fibers, nanofibers and / or nanotubes to generate the corona discharge. The invention contemplates carbon fiber electrodes with or without a polymer matrix to form a composite, and a supporting configuration in which the fibers are wrapped helically around a supporting rod that extends along the length of the electrode. Another supporting configuration includes the fibers stretched across the gas flow path. Yet another supporting configuration includes mounting the fibers along the length of the support rod substantially parallel to the rod.

Owner:OHIO UNIV

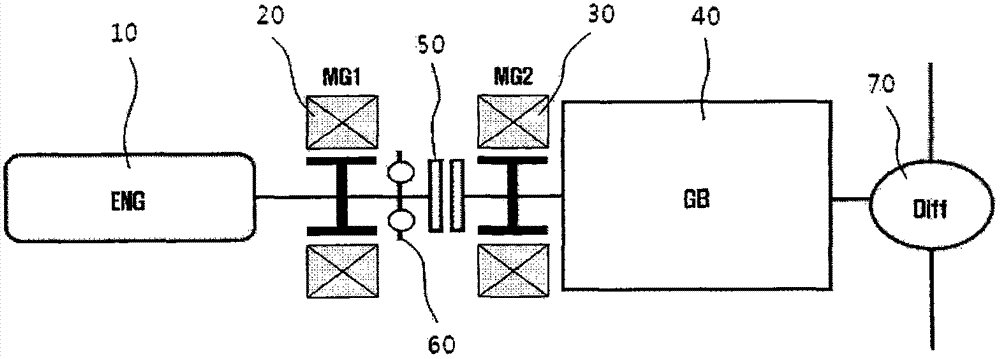

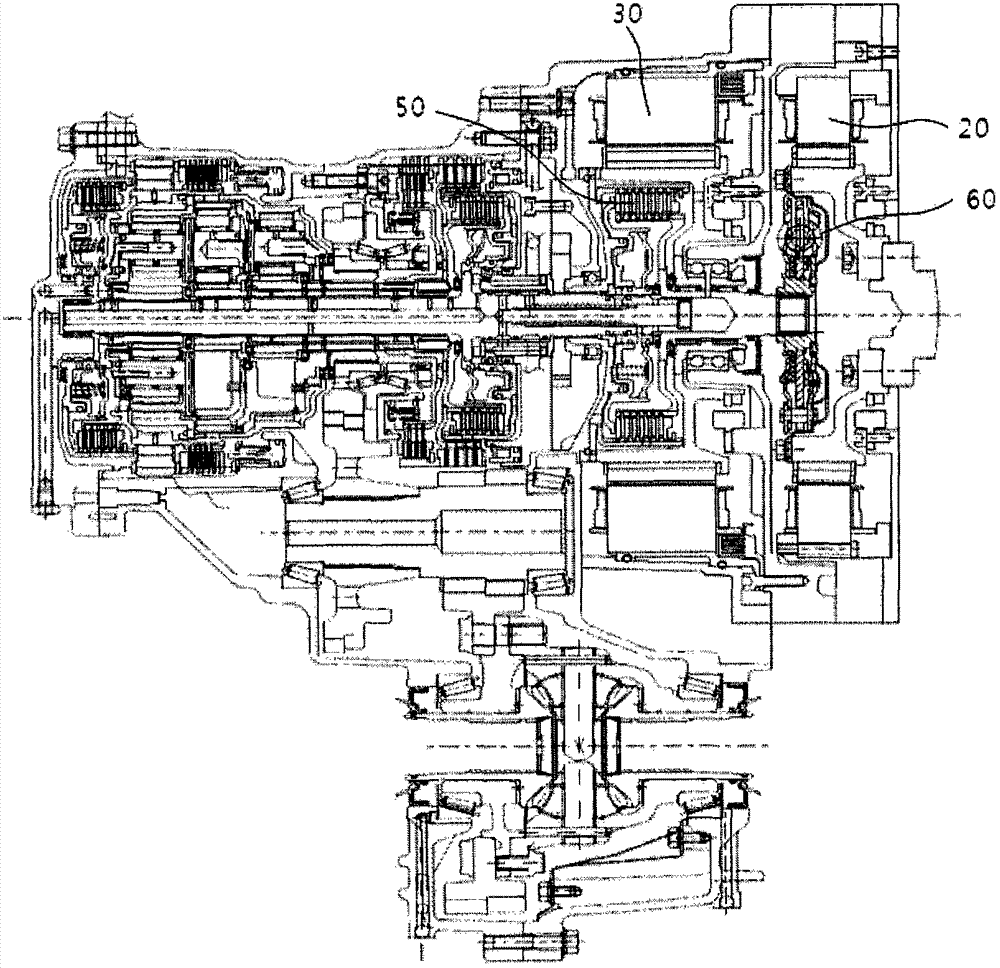

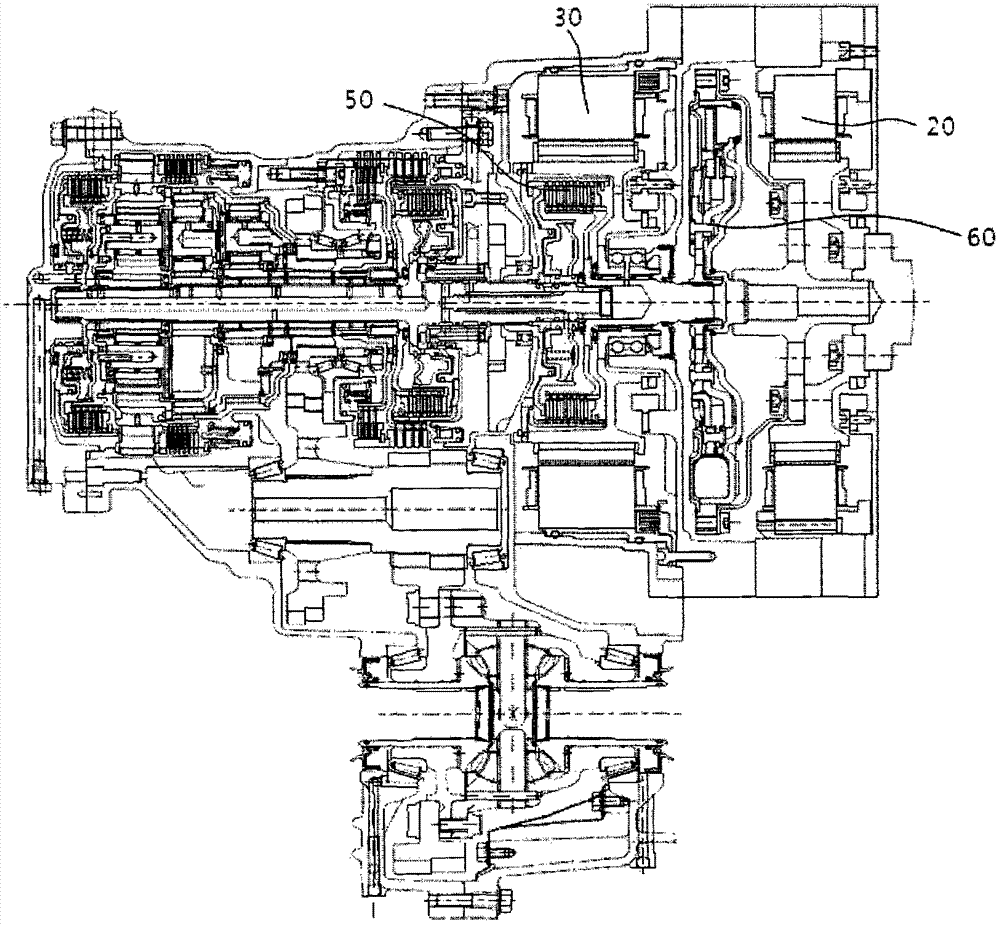

Power delivery device for vehicle

InactiveCN103158527AImprove stabilityImprove charging characteristicsHybrid vehiclesMechanical apparatusDrive shaftControl theory

Disclosed is a power delivery device for a vehicle that improves power delivery efficiency. More specifically, the power delivery device includes a first motor having a first drive shaft directly connected to an output shaft of an engine, a second motor having a second drive shaft directly connected to an input shaft of a gearbox, and a clutch selectively connecting the output shaft of the engine with the input shaft of the gearbox.

Owner:HYUNDAI MOTOR CO LTD

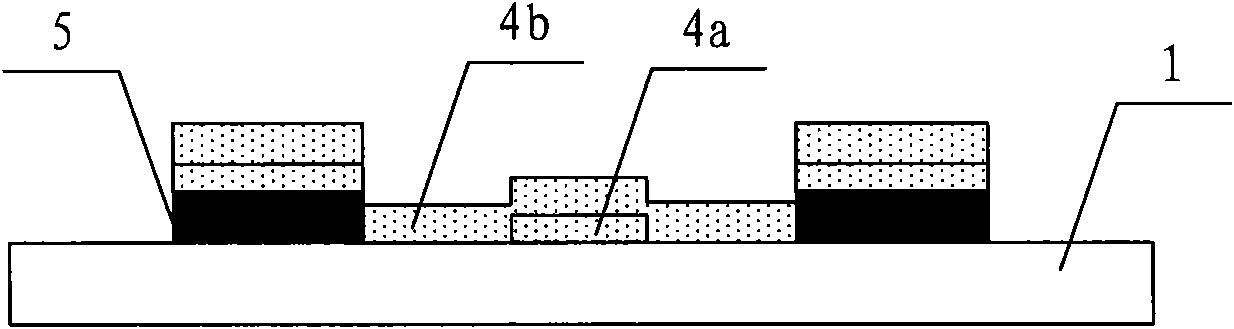

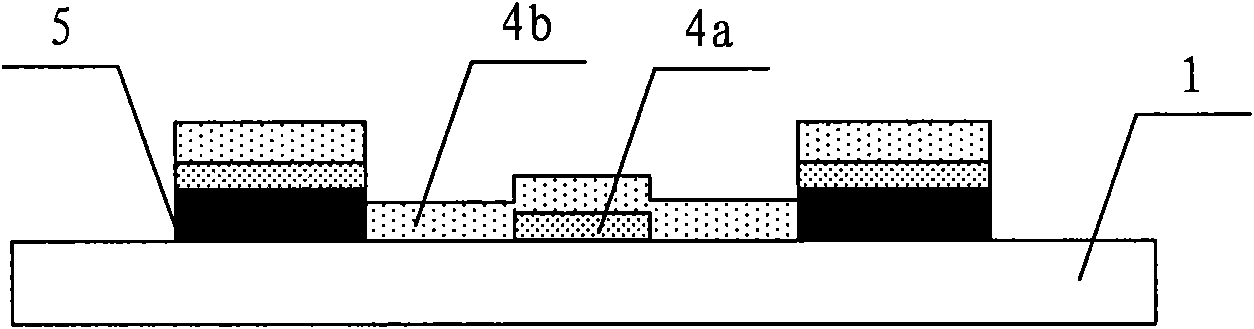

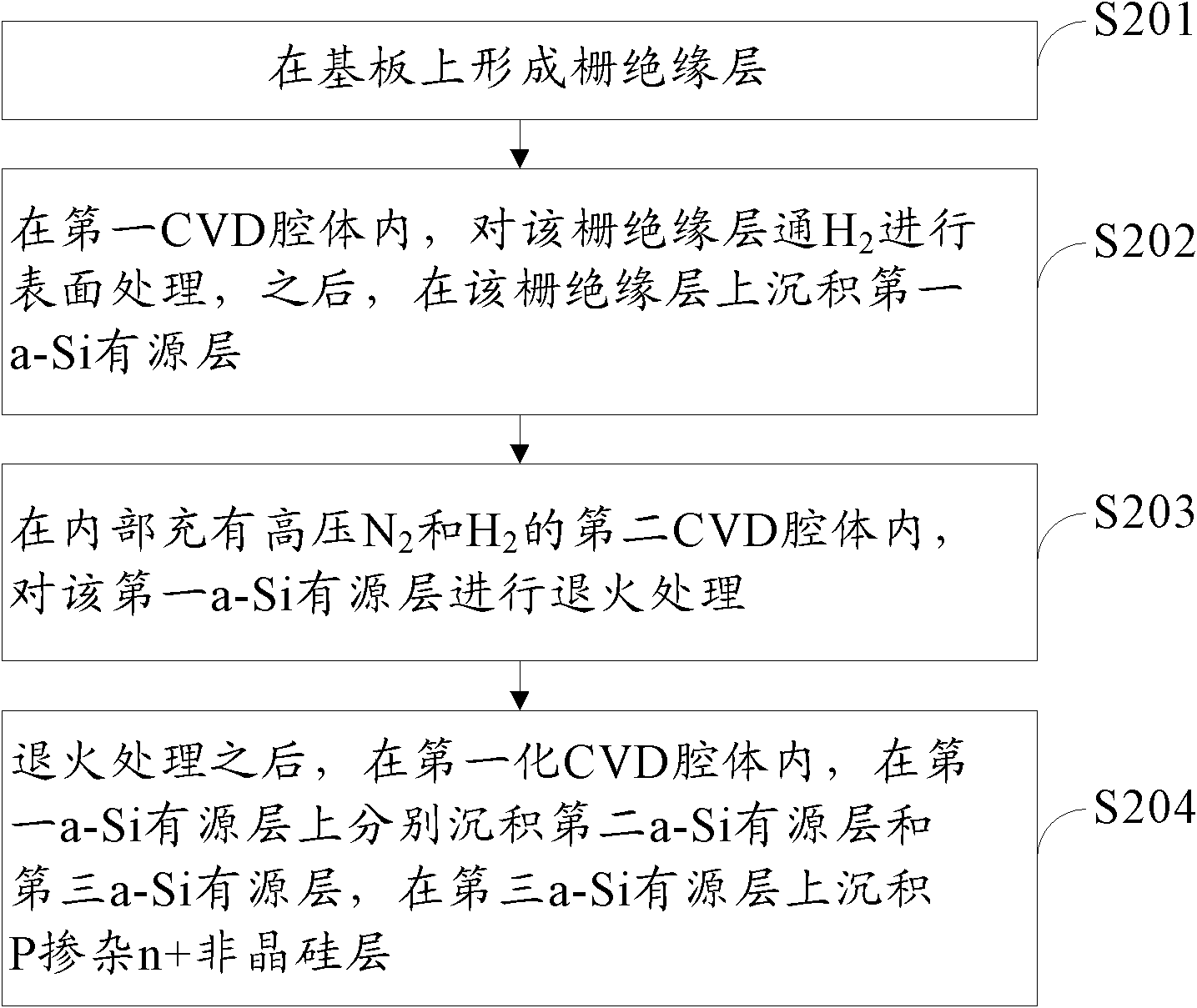

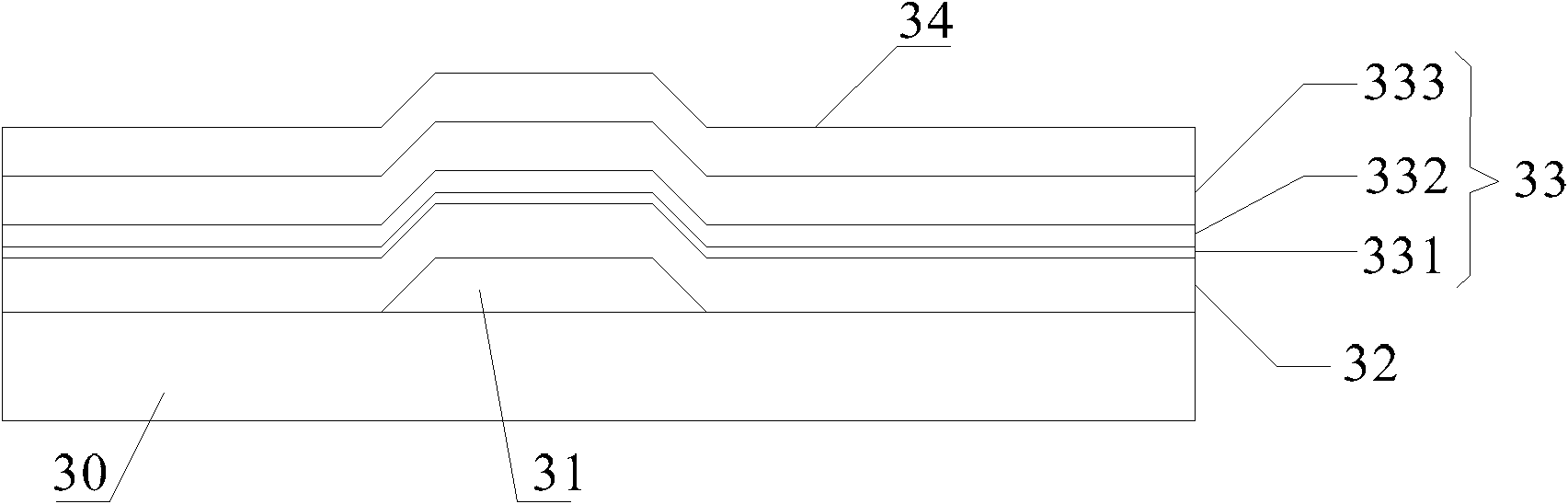

TFT (thin film transistor) array substrate as well as production method and manufacturing equipment for same

InactiveCN102655115AImprove charging characteristicsFast transmissionSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayAmorphous silicon

The embodiment of the invention provides a TFT (thin film transistor) array substrate as well as a production method and manufacturing equipment for the same, relating to the field of manufacturing for thin-film-transistor liquid crystal displayer, being capable of improving the charge characteristic of TFT and increasing the carrier mobility of TFT, as well as being simple and convenient in realization, and low in cost. The method comprises the following steps of: forming a gate insulating layer on a substrate; charging H2 to perform surface treatment on the gate insulating layer in a first CVD (chemical vapour deposition) cavity, and then depositing a first a-Si active layer on the gate insulating layer; performing annealing treatment on the first a-Si active layer in a second CVD cavity internally charged with high-pressure N2 and H2; and after the annealing treatment, depositing a second a-Si active layer and a third a-Si active layer on the first a-Si active layer respectively, and depositing a P-doped n<+> amorphous silicon layer on the third a-Si active layer in the first CVD cavity. The method provided by the embodiment of the invention is used for manufacturing a TFT array substrate.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Toner compositions

ActiveUS20060121381A1Improve charging characteristicsReduced RH charging sensitivityDevelopersCharge controlTitanium oxide

A toner composition comprising a binder, colorant, and a charge control surface additive mixture comprising a mixture of a first titanium dioxide possessing a first conductivity and a second titanium dioxide possessing a second conductivity and which second conductivity is dissimilar than the first conductivity; wherein the mixture of the first titanium dioxide and the second titanium dioxide is selected in a ratio sufficient to impart a selected triboelectric charging characteristic to the toner composition.

Owner:XEROX CORP

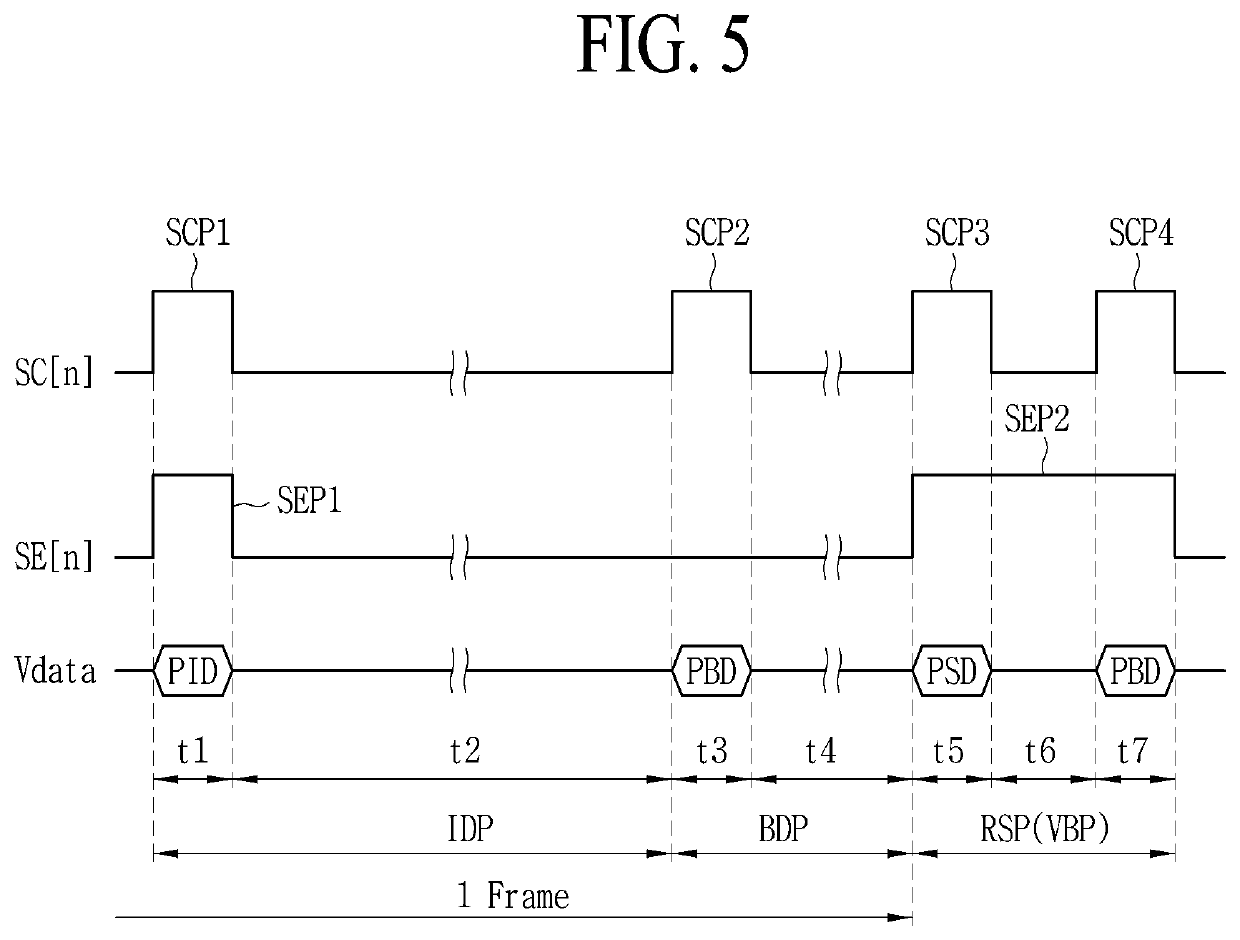

Gate driving circuit and light emitting display apparatus comprising the same

ActiveUS20210201767A1Improve charging characteristicsMinimize voltage dropStatic indicating devicesDriver circuitHemt circuits

A gate driving circuit and a light emitting display apparatus comprising the same are discussed, in which a charging characteristic of a control node is improved. The gate driving circuit comprises first to mth stage circuits, wherein each of the first to mth stage circuits includes first to third control nodes, a node control circuit controlling a voltage of each of the first to third control nodes, and an output buffer circuit outputting each of a scan signal, a sense signal and a carry signal in accordance with each of the first to third control nodes, the node control circuit including a node setup circuit charging a first gate high potential voltage in the first control node in response to a first carry signal supplied from a front stage circuit.

Owner:LG DISPLAY CO LTD

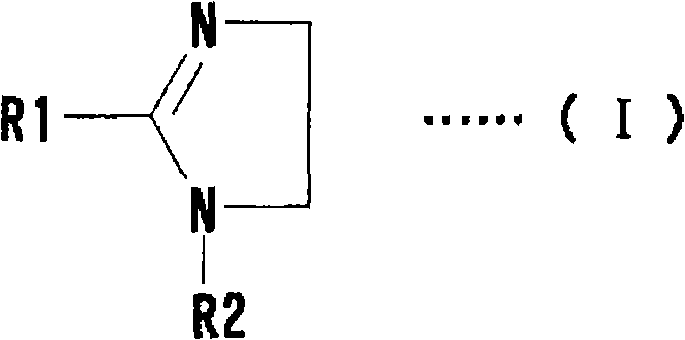

Liquid developer and image forming apparatus

InactiveCN101539730AImprove dispersion stabilityImprove charging characteristicsElectrographic process apparatusDevelopersPolymerHydroxystearic Acid

The invention provides a liquid developer having both superior dispersibility and a charge characteristic of toner particles, and further an image forming apparatus using the same. The liquid developer is characterized by comprising an insulation liquid, a dispersant dissolved in the insulation liquid, a dispersant, and a charge control agent represented by the following chemical formula (I), wherein R1 represents an alkyl group or alkenyl group having a carbon number in the range of 8 to 22, and R2 represents a hydroxyalkyl group. It is preferred that a polymer dispersant having a 12-hydroxystearic skeleton is selected as the dispersant, and R2 represents a hydroxyalkyl group having a carbon number from 1 to 4.

Owner:SEIKO EPSON CORP

Particles for electrophoretic media

InactiveUS20060222976A1SimplifyReduce and eliminateElectrographic processes using photoelectrophoresisElectrographic process apparatusPigment particlePolymer

Compositions of encapsulated triboelectrically charged particles and methods for making them using a spinning disc process are disclosed. The methods can be used to make charged pigment particles embedded in a neutral polymer matrix. The polymer matrix keeps oppositely charged pigment particle from agglomerating. The particles can be used for electrophoretic displays.

Owner:XEROX CORP

Toner

ActiveUS10539899B2Improve charging effectImprove charging characteristicsDevelopersPolymer scienceComposite material

A toner comprising a toner particle that contains a binder resin, wherein the surface of the toner particle has a reaction product of a polyhydric acid and a compound that contains a group 4 element.

Owner:CANON KK

Oxidized mixed cyclic phenol sulfides, and charge control agents and toners using the same

ActiveUS20090042120A1Reduce the amount of solutionSpeed up charging risetimeOrganic chemistryOther chemical processesPHENOL LIQUIDCharge control

The present invention discloses an oxidized mixed cyclic phenol sulfide which is a mixture of the oxidized cyclic phenol sulfide wherein in is 8 and the oxidized cyclic phenol sulfide wherein m is an integer other than 8, the oxidized cyclic phenol sulfide being represented by the following formula (1):wherein R is a straight or branched alkyl group having 1 to 6 carbon atoms, m is an integer from 4 to 9, and n is 1 or 2; or an oxidized cyclic phenol sulfide of formula (1) wherein m is 8. The present invention also discloses a charge control agent which comprises the above sulfide(s) as the active ingredient; and a toner which comprises the charge control agent, a coloring agent and a binder resin. This charge control agent is particularly useful for color toners, and it speeds up charging risetime, and has a high charge amount and charging characteristics excellent in environmental stability. Further, the charge control agent is safe since it does not have any problem with the waste regulations.

Owner:HODOGOYA CHEMICAL CO LTD

Liquid developer and image forming apparatus

InactiveCN101482710AImprove charging characteristicsExcellent long-term dispersion stabilityElectrographic process apparatusDevelopersImage formationEngineering

The invention provides a liquid developer with electropositive character superiority, toner particle long-term dispersible superiority; in addition, the invention also provides an image forming device using the liquid developer. The liquid developer of the invention comprises an insulation liquid, the toner particles and dispersant. The surface of the toner particle is at least coated with a rosin resin; the dispersant has amine value; the amine value of the dispersant is preferably selected as 1-100 mg KOH / g. The content of the dispersant is 0.2-10 weight part as to the 100 weight part of the toner particles. The sintering point of the rosin resin is preferably selected as 80-190 centigrade.

Owner:SEIKO EPSON CORP

Electrophoretic particles, electrophoretic dispersion liquid, display sheet, display device, and electronic equipment

ActiveUS9645467B2Dispersibility mainlyImprove charging characteristicsElectrographic processes using photoelectrophoresisTenebresent compositionsElectrophoresisOrganic group

Electrophoretic particle include a core particle; a siloxane-based compound that is bonded to a surface of the core particle and contains a connection structure in which a plurality of siloxane bonds are serially connected to each other; and a polarizing group that is an organic group bonded to the surface of the core particle, contains a main skeleton and a substituent bonded to the main skeleton, and has unevenly distributed electrons on the particle side of the main skeleton or the opposing side thereof.

Owner:E INK CORPORATION

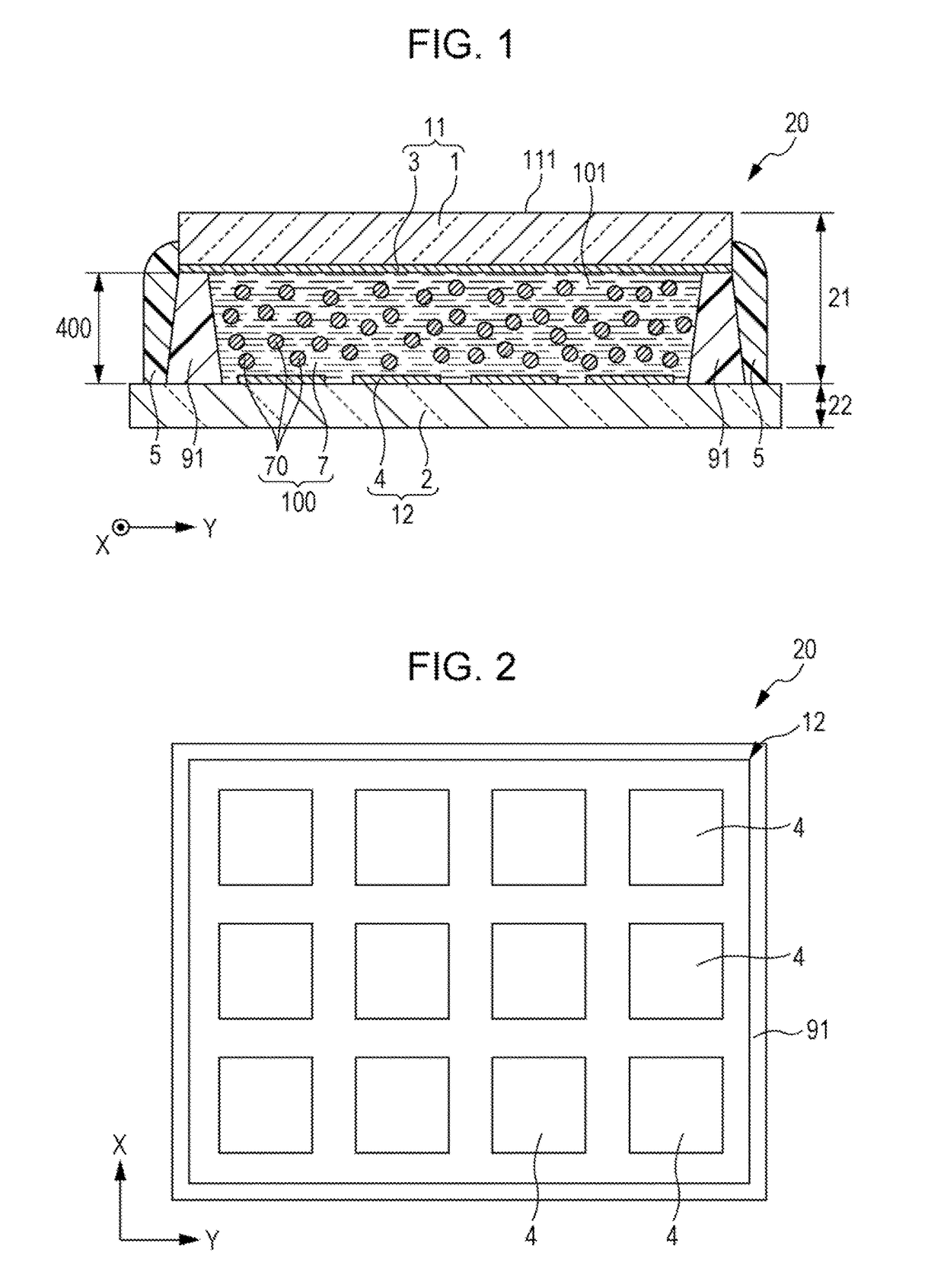

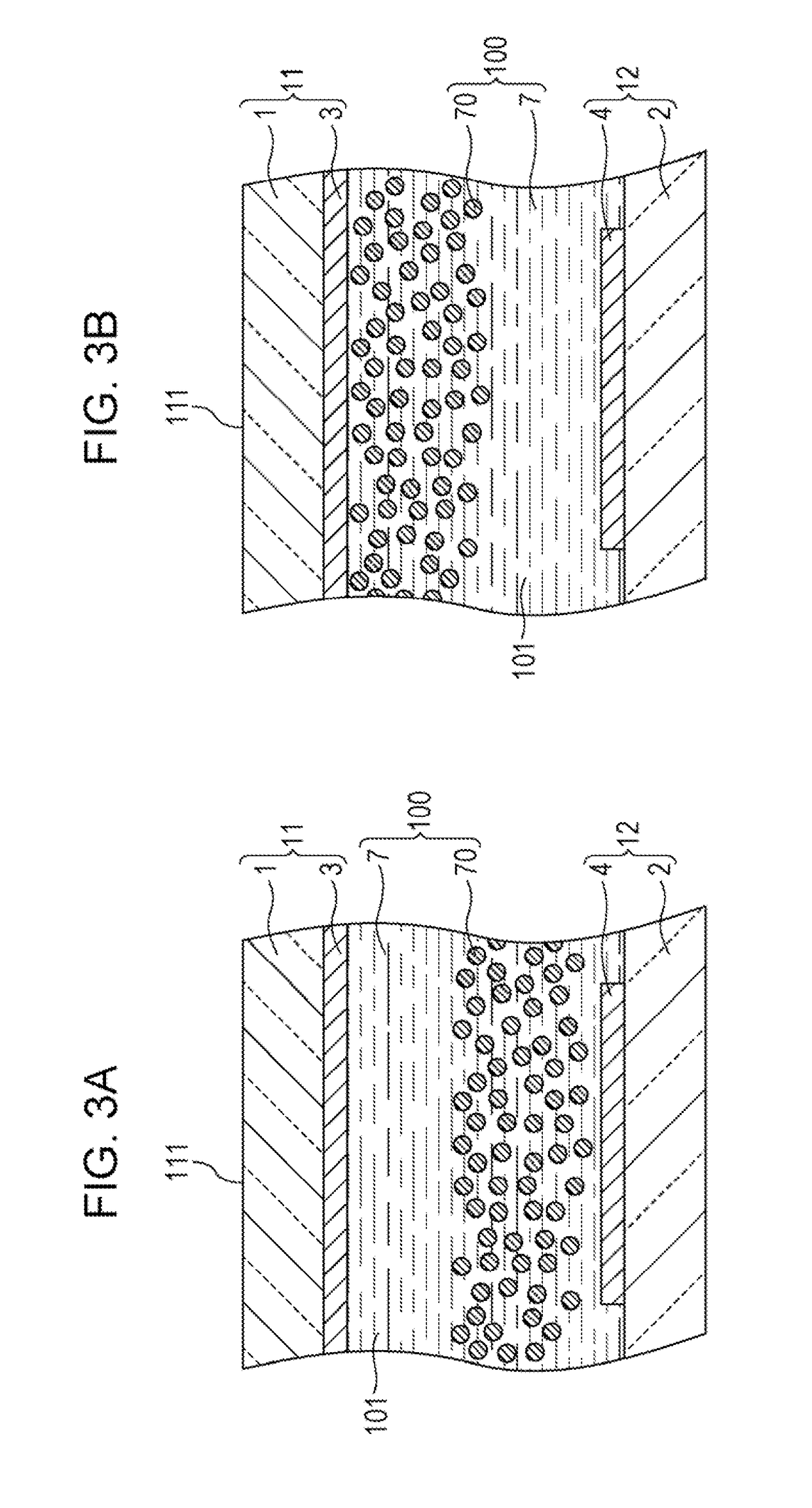

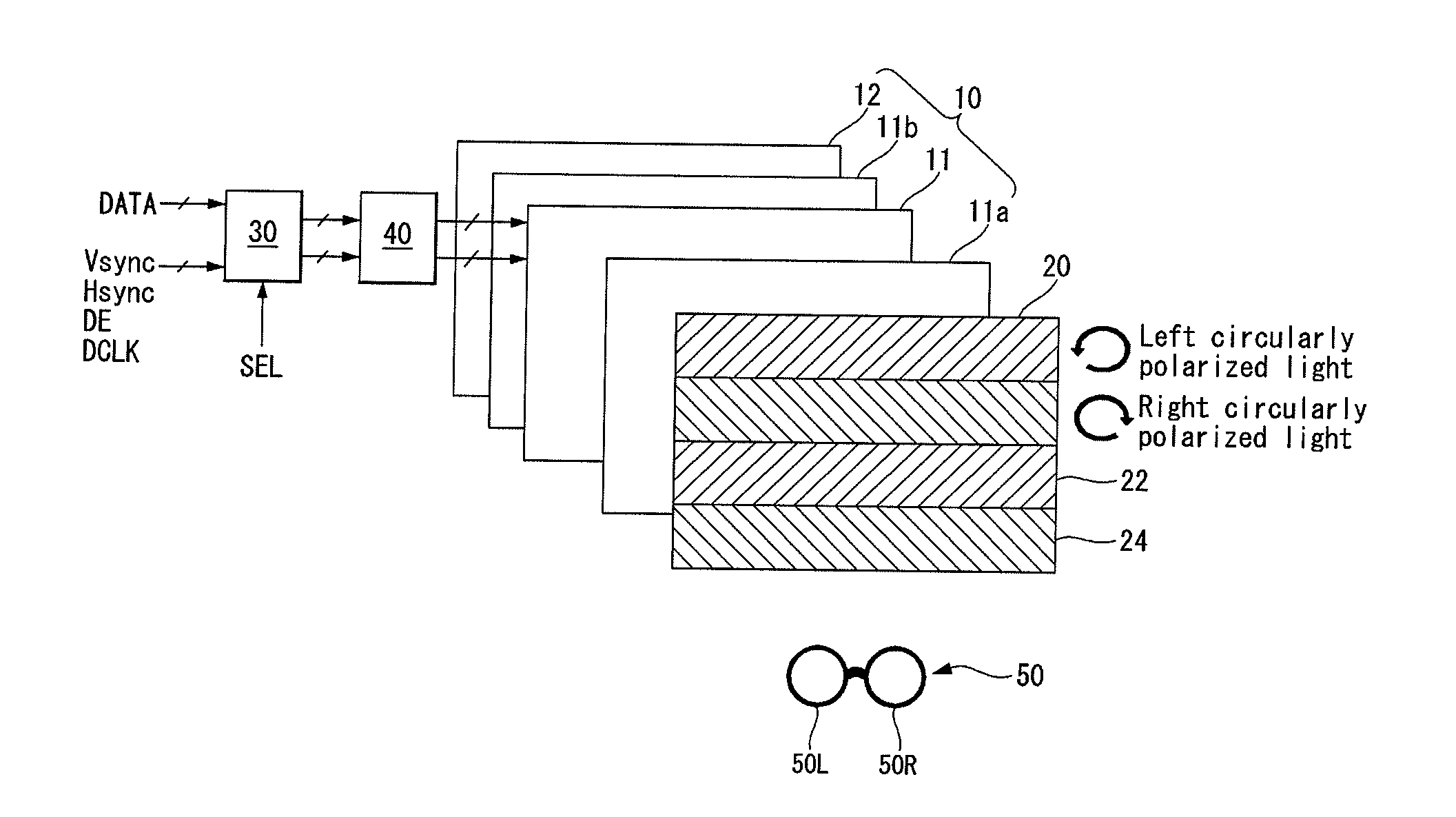

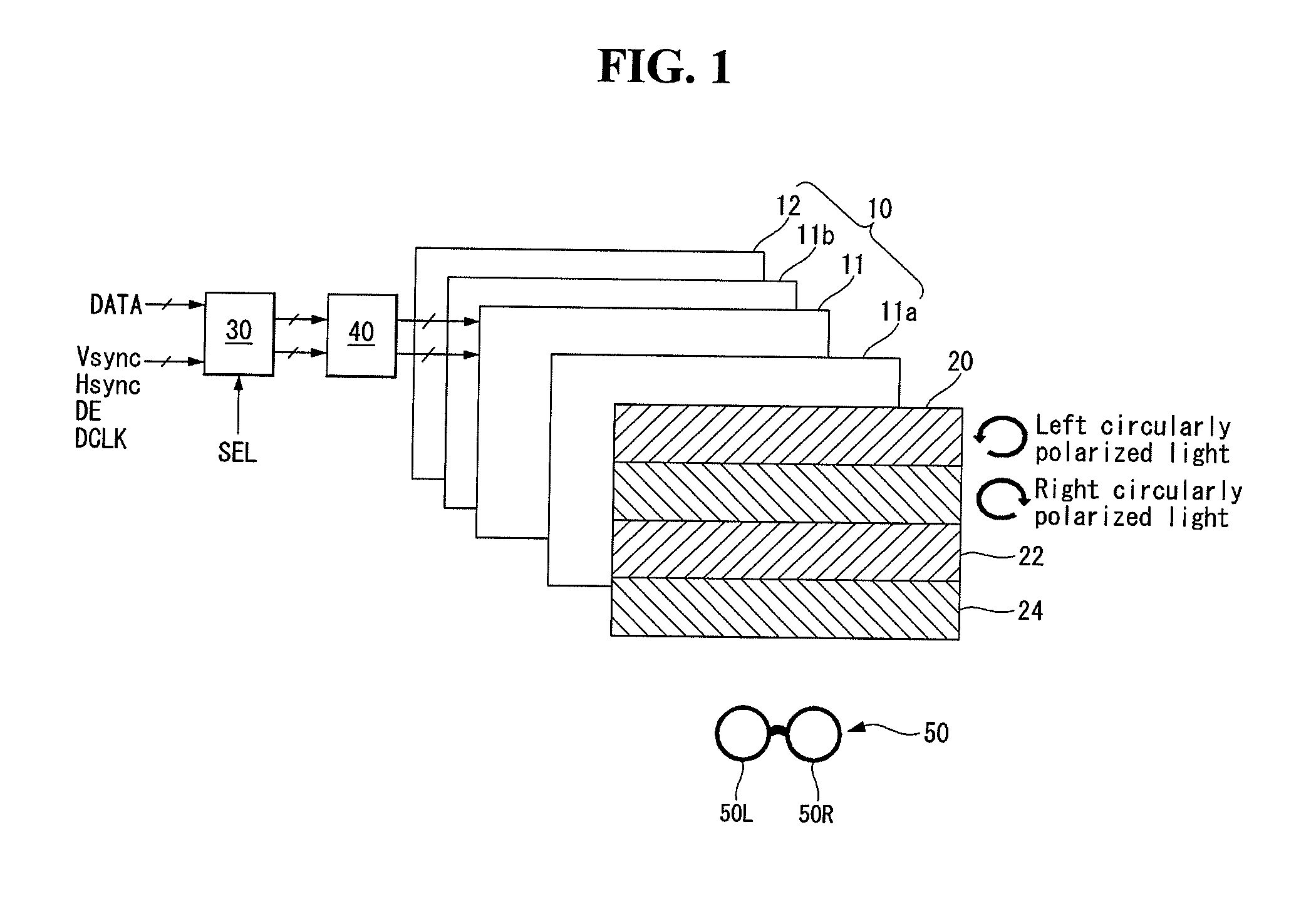

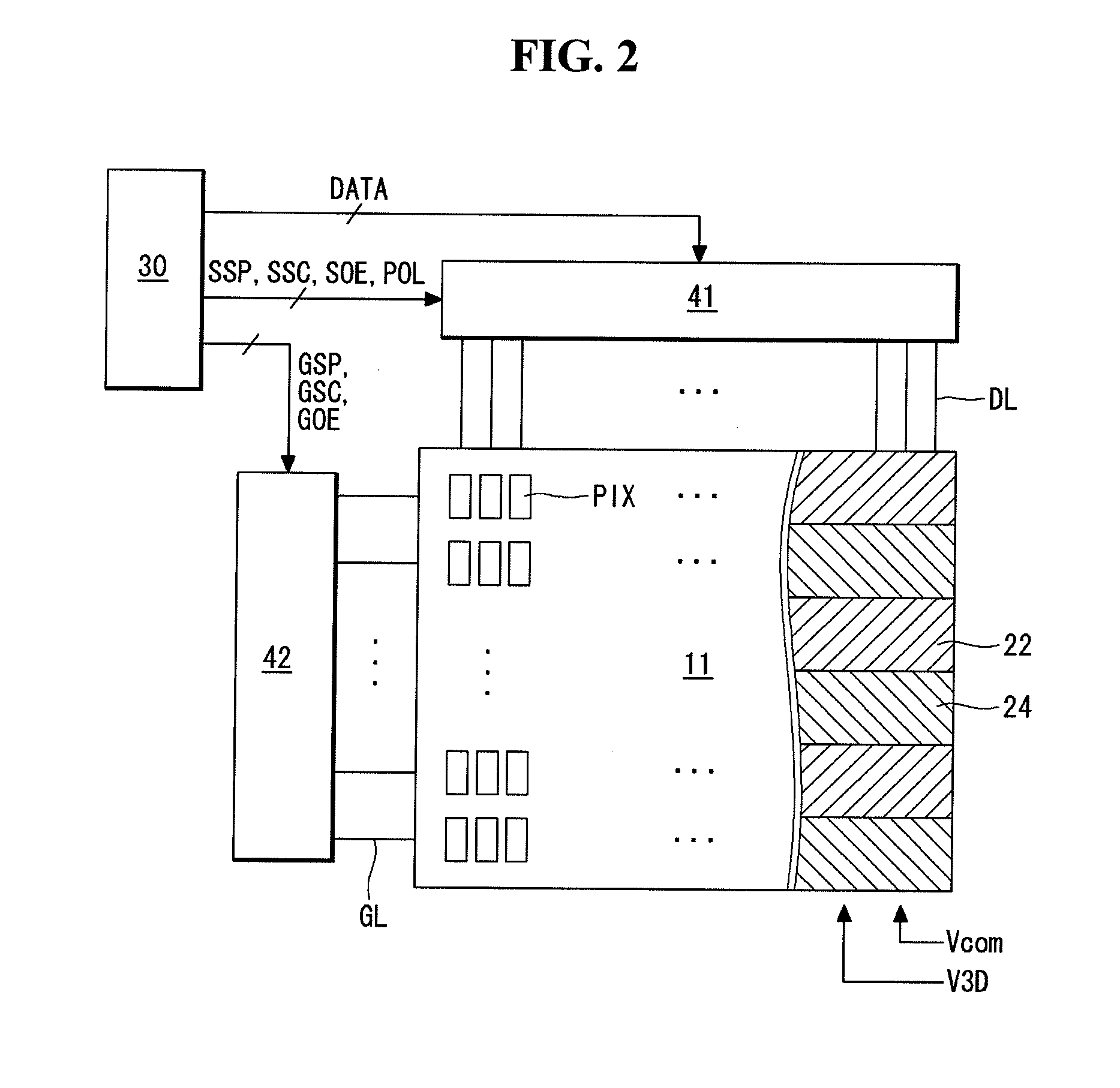

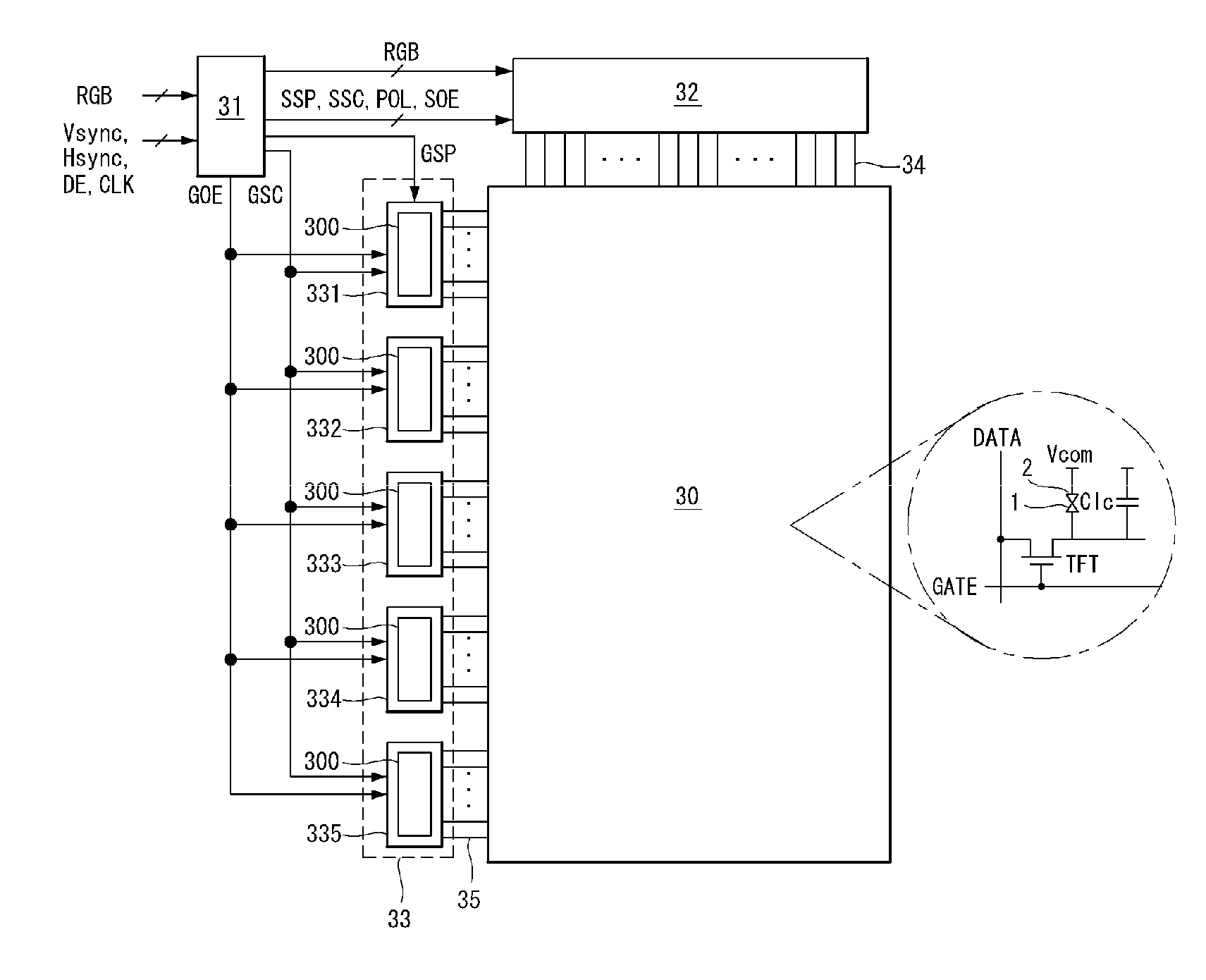

Stereoscopic image display

ActiveUS20130106839A1Improving data charging characteristicReduce aperture ratioSteroscopic systemsNon-linear opticsDisplay deviceEngineering

A stereoscopic image display according to an embodiment includes: a main display section including a first liquid crystal cell connected to a data line through a first switch TFT and connected to a common line supplied with a common voltage and a first storage capacitor; and an auxiliary display section including a second liquid crystal cell connected to the data line through a second switch TFT and connected to the common line through a discharge control TFT and a second storage capacitor.

Owner:LG DISPLAY CO LTD

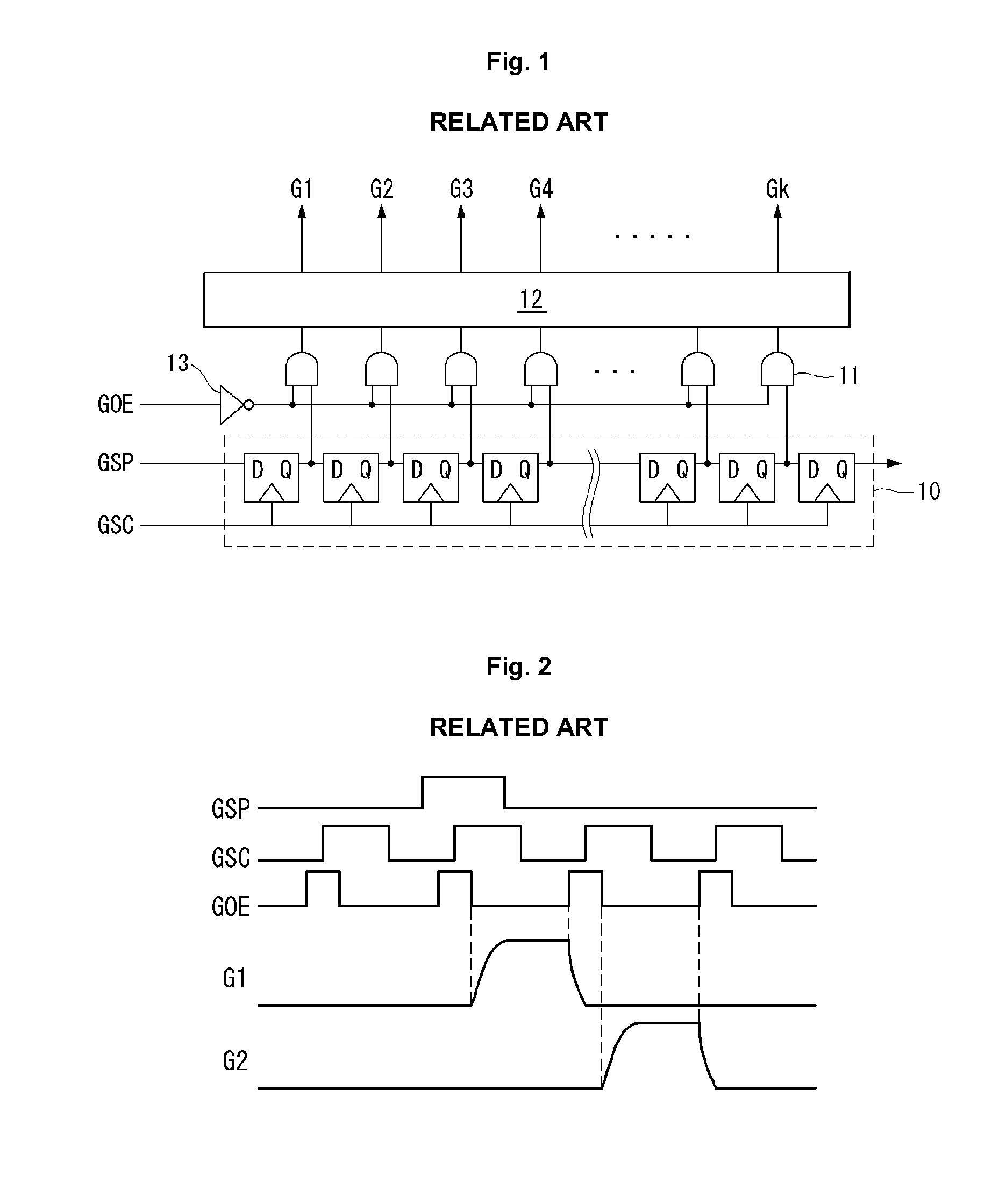

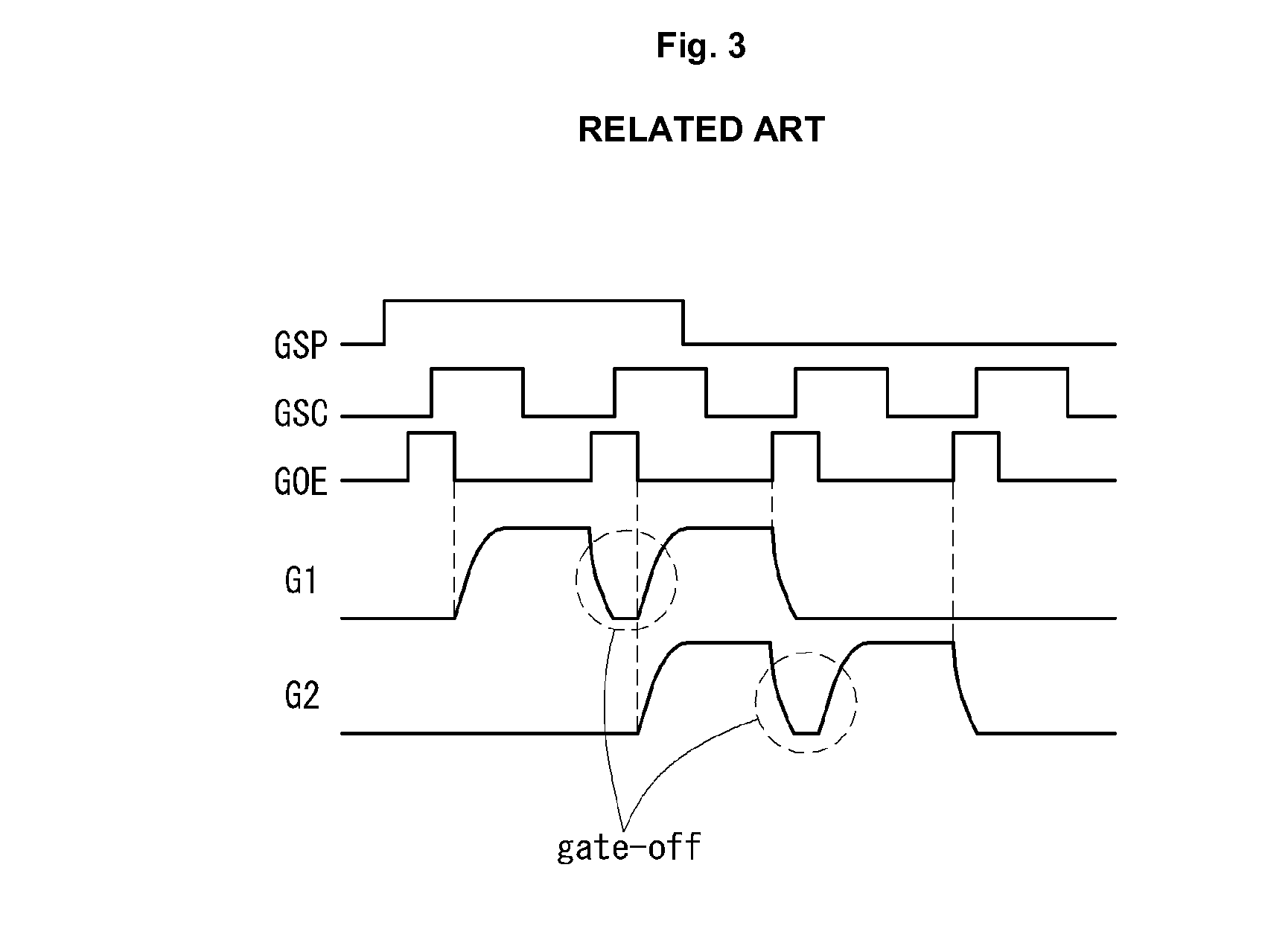

Display device and driving method thereof

ActiveUS20150187297A1Improve charging characteristicsAvoid it happening againCathode-ray tube indicatorsNon-linear opticsDisplay deviceEngineering

A disclosed display device includes a display panel with data lines and gate lines, the gate lines including odd-numbered gate lines and even-numbered gate lines. The display device also includes a timing controller to generate a gate output enable signal, and a gate output enable signal division circuit to extract odd-numbered high logic periods of the gate output enable signal to output a first gate output enable signal and to extract even-numbered high logic periods of the gate output enable signal to output a second gate output enable signal. The display device further includes a gate driver to supply a first gate pulse to an odd-numbered gate line in response to the first gate output enable signal and a second gate pulse to an even-numbered gate line in response to the second output enable signal.

Owner:LG DISPLAY CO LTD

Toner having Improved Charge Characteristics

ActiveUS20100159378A1Improve print qualityImprove the level ofDevelopersCerium oxideElectrical and Electronics engineering

This invention provides a toner with improved charge and charge stability by suitable addition of extra particulate additives (EPA) such as aluminum cerium oxide and / or cerium zirconium oxide. The additives may be combined with toner in a conical mixer having selected temperature control. The invention also provides toner which may provide reduced print quality defects such as ghosting or residual image and fade-to-color.

Owner:LEXMARK INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com