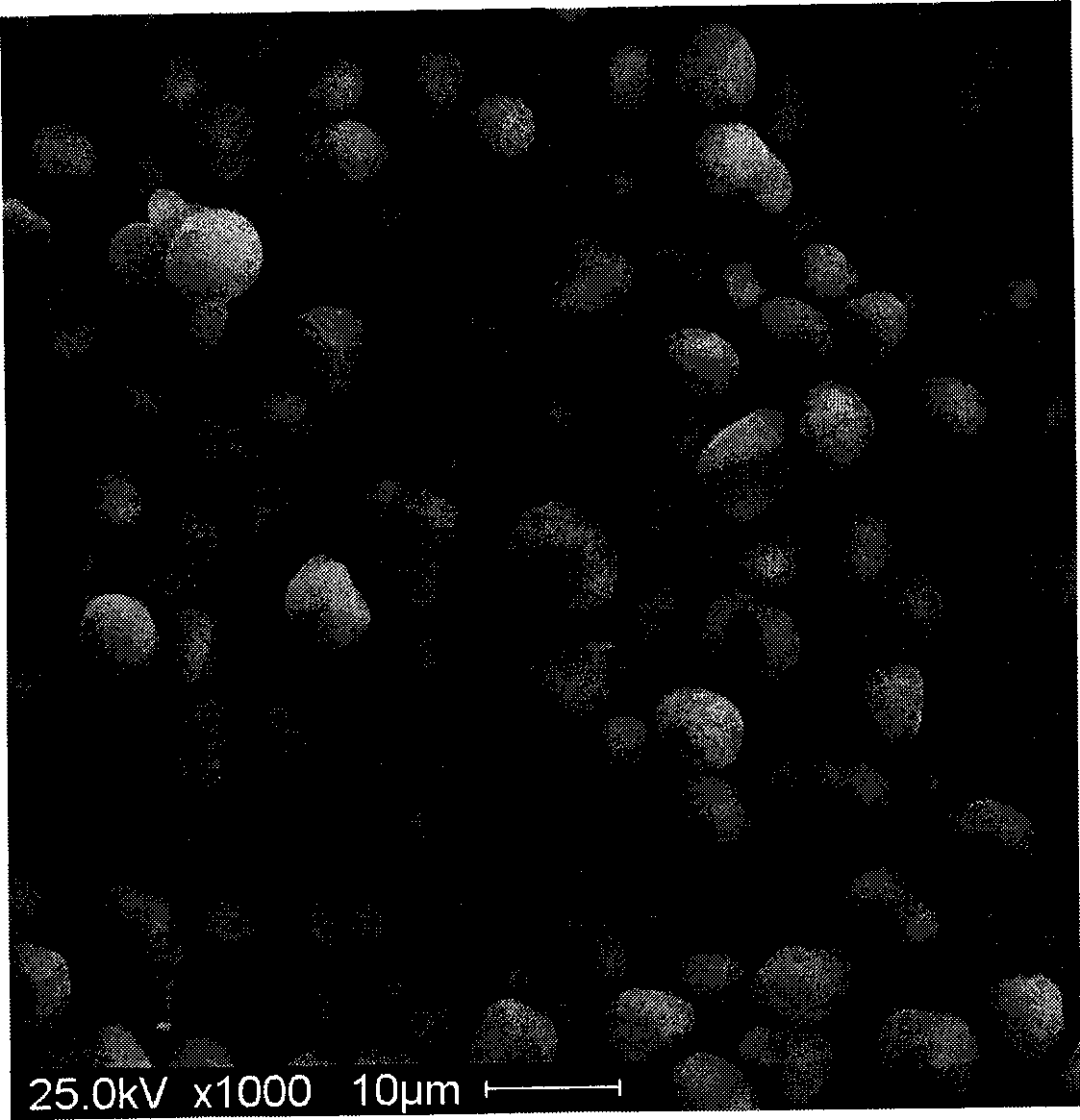

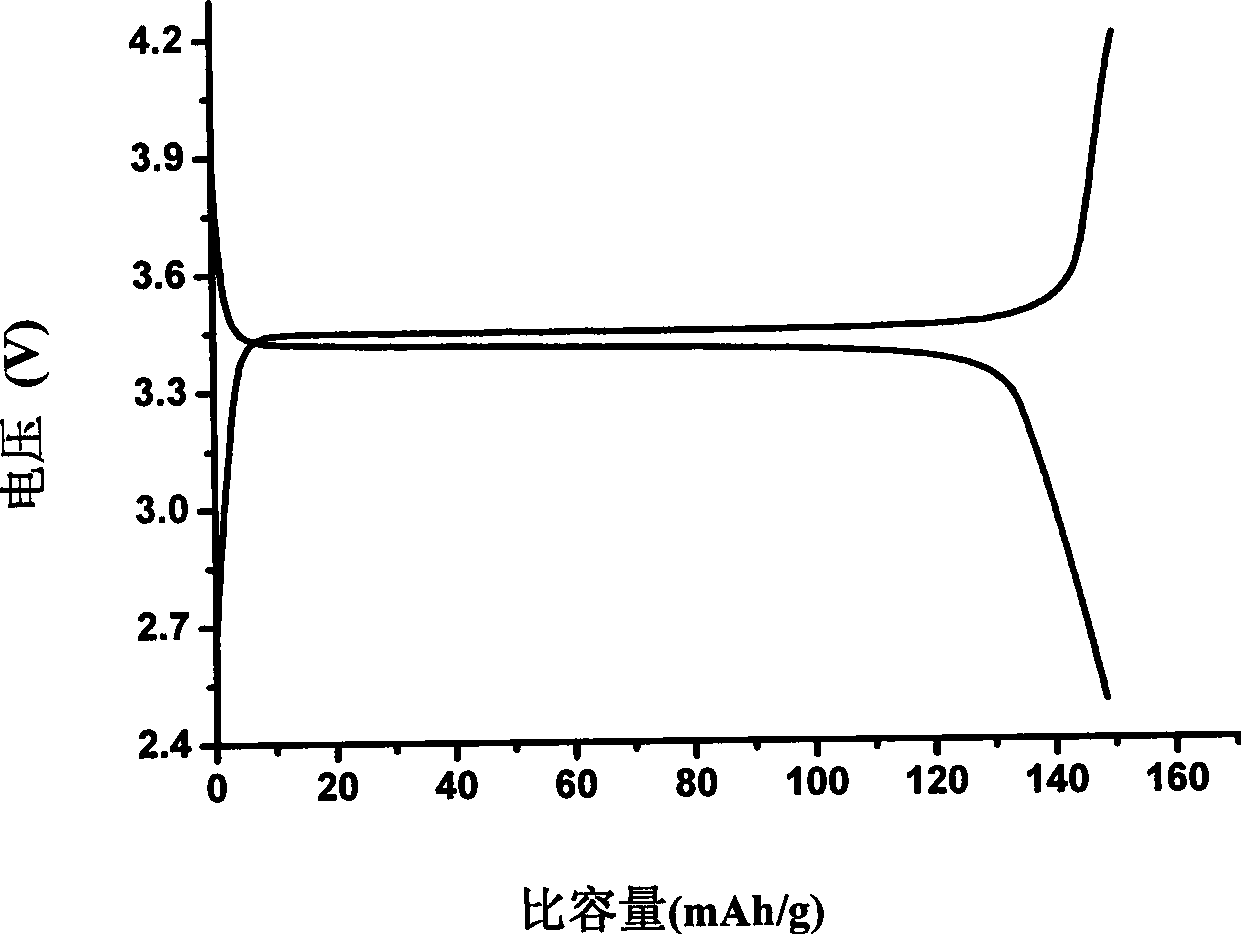

Method for preparing high-density spherical lithium iron phosphate for lithium ion power battery

A power battery, lithium iron phosphate technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve problems such as fluctuations in the addition speed of iron salts and phosphorus source solutions, harsh control conditions, and fast addition speed, etc. Achieving the effects of abundant raw materials, narrow particle size distribution and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method for high-density spherical lithium iron phosphate for lithium-ion power batteries, comprising the following steps:

[0028] (1) acid, ferric source, phosphorus source are made into mixed aqueous solution, wherein the concentration of iron is 0.2-3mol / L, and the concentration of phosphorus is 0.2-3mol / L, and the acid consumption is the hydrogen in the acid: iron=( 0.5-5):1 (molar ratio).

[0029] (2) Prepare the alkali into an aqueous solution with a concentration of 2-12mol / L.

[0030] (3) The above-mentioned mixed aqueous solution and the aqueous solution of the alkali are respectively continuously input into the reaction kettle with stirring and a thermometer with a pump, the liquid addition rate of the mixed aqueous solution is controlled, and the liquid addition speed of the alkali aqueous solution is adjusted simultaneously, and the reaction liquid in the reaction kettle is controlled. The pH value is 1-5, and the temperature of the reaction s...

Embodiment 1

[0035] Prepare a mixed aqueous solution of hydrochloric acid, ferric chloride, and phosphoric acid, wherein the concentration of iron ions is 1.5 mol / L, the concentration of phosphoric acid is 1.5 mol / L, and the concentration of hydrochloric acid is 0.5 mol / L. Prepare an ammonia solution with a concentration of 6 mol / L. Use the metering pump to respectively input the mixed aqueous solution and the ammonia solution into the reactor that has been filled with 8 liters of deionized water in advance (the reactor volume is 30 liters) to carry out coprecipitation reaction, adjust the liquid addition speed of the ammonia solution, and control the reaction kettle. The pH value of the reaction solution is 3.5±0.05. Control the temperature in the reactor to be 65°C. After continuous feeding for 20 hours, the feeding was stopped, and the material in the reactor was discharged and filtered. Wash the solid product with deionized water at 70°C until the pH value of the washing water is gre...

Embodiment 2

[0037] Prepare a mixed aqueous solution of nitric acid, ferric nitrate, and ammonium dihydrogen phosphate, wherein the concentration of iron ions is 1.5 mol / L, the concentration of phosphate is 1.5 mol / L, and the concentration of nitric acid is 2 mol / L. Prepare an ammonia solution with a concentration of 6 mol / L. Use the metering pump to respectively input the mixed aqueous solution and the ammonia solution into the reactor that has been filled with 8 liters of deionized water in advance (the reactor volume is 30 liters) to carry out coprecipitation reaction, adjust the liquid addition speed of the ammonia solution, and control the reaction kettle. The pH value of the reaction solution is 3.8±0.05. Control the temperature in the reactor to be 55°C. After continuous feeding for 20 hours, the feeding was stopped, and the material in the reactor was discharged and filtered. Wash the solid product with deionized water at 70°C until the pH value of the washing water is greater th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com