Preparation method and applications of nanometer titanium dioxide @ Fe-based MOF visible light composite catalyst

A nano-titanium dioxide and composite catalyst technology, which is applied in the field of environmental pollution control, can solve the problems of low solar energy utilization rate of photocatalysts, complicated preparation and high electron-hole recombination rate, and achieves easy control of preparation parameters, broad application prospects and process cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

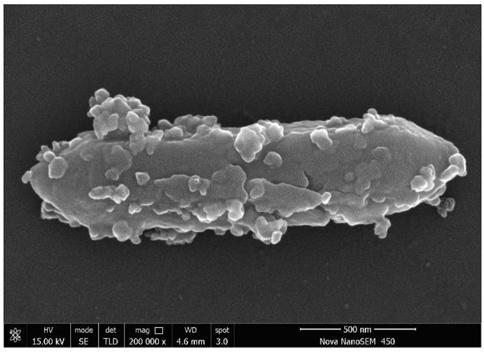

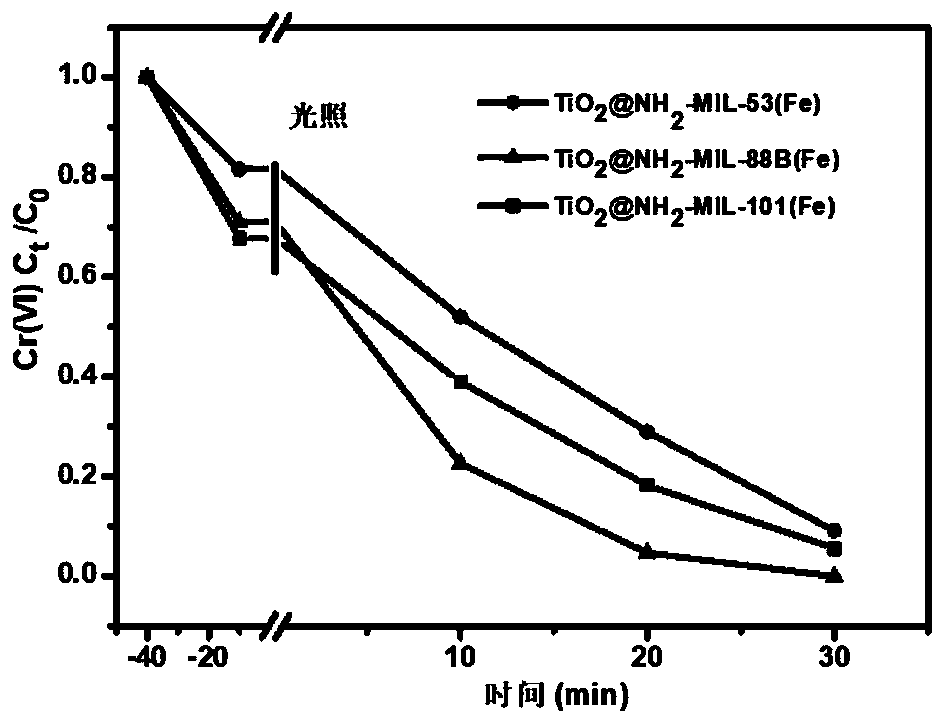

[0036](1) Take 0.017g TiO 2 (P25), 0.27g ferric chloride hexahydrate (FeCl 3 .6H 2 O) and 0.18g of 2-aminoterephthalic acid were dissolved in 20mL of N,N-dimethylformamide, ultrasonically dispersed; transferred to a polytetrafluoroethylene-lined autoclave, reacted at 110°C for 12h, and centrifuged , washing, suction filtration, and vacuum drying at 70°C for 8 hours to obtain TiO 2 @NH 2 - MIL-88B(Fe)(TM-b) photocatalyst. In this catalyst, the molar ratio of titanium dioxide to iron-based MOF is 10%.

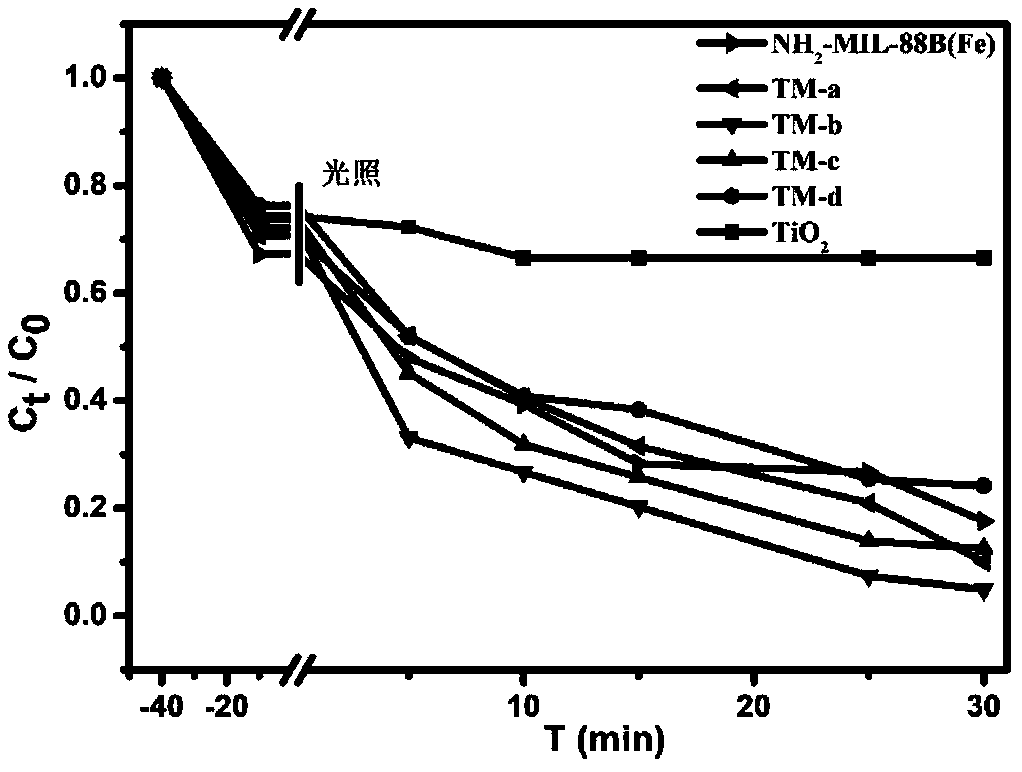

[0037] (2) Prepare a 0.2 mmol / L Cr(VI) solution at room temperature, take 40 mL of the solution in a 50 mL photoreaction tube, add 20 mg of the photocatalyst obtained in (1), and 3 mg of small molecular organics.

[0038] (3) Adjust the pH of the solution to 7, fully stir for 40 minutes under dark conditions, irradiate with a 500W xenon lamp, take samples at intervals, and measure the residual Cr(VI) concentration by the national standard method.

[0039] TiO is obtained in...

Embodiment 2

[0046] The difference between this embodiment and Example 1 is that the TiO described in step (1) 2 The addition amount of (P25) is 0.0085g, other is identical with embodiment 1, obtains photocatalyst (TM-a). See the experimental results figure 2 , depicts the time-dependent trend of the ratio of the Cr(VI) concentration to the initial Cr(VI) concentration during the reaction.

[0047] In the photocatalyst (TM-a), the molar ratio of titanium dioxide to iron-based MOF is 5%.

Embodiment 3

[0049] The difference between this embodiment and Example 1 is that TiO in step (1) 2 (P25) was added in an amount of 0.0255 g, and the others were the same as in Example 1 to obtain a photocatalyst (TM-c). See the experimental results figure 2 , depicts the time-dependent trend of the ratio of the Cr(VI) concentration to the initial Cr(VI) concentration during the reaction. In the photocatalyst (TM-c), the molar ratio of titanium dioxide to iron-based MOF is 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com