Lignin degradation solution and preparation method thereof as well as method for degrading lignin by using lignin degradation solution

A technology of lignin and degradation liquid, applied in the directions of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problem of difficult to achieve efficient biodegradation of lignin, and achieve the effect of improving the degradation conversion efficiency and the degradation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of laccase LacT derived from Polyporus:

[0033] A. Draw the inoculum block from the slant culture of the polypore, inoculate it into 100ml of potato liquid seed medium, place it on a shaker and cultivate it at a speed of 200r / min for 8 days at a temperature of 25°C to obtain a liquid strain;

[0034] B. Insert the prepared liquid strain into the laccase-producing medium with an inoculum of 10% by volume, place the culture at 25° C. for static cultivation for 6 days, add 1 mM veratrol, and continue to cultivate respectively for 3, After 10 and 15 days, the culture was filtered to obtain crude laccase enzyme solution;

[0035] The preparation method of the laccase enzyme production medium is as follows: add 20g bran per 100ml Kirk nitrogen-limited liquid medium, and sterilize at 100°C for 40min.

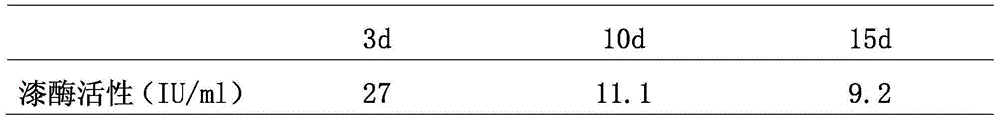

[0036] C. Determination of laccase enzyme activity, the results are shown in Table 1, select the 3d laccase crude enzyme solution with the highest enzyme...

Embodiment 2

[0040] Example 2 Preparation of laccase LacG derived from Ganoderma lucidum:

[0041] A. Draw the inoculum piece from the slant culture of Ganoderma lucidum, inoculate it into 100ml potato liquid seed medium, place it on a shaker, shake it at a speed of 50r / min for 2 days, and obtain a liquid strain at a temperature of 37°C;

[0042] B. Insert the prepared liquid strain into the laccase enzyme production medium with an inoculum size of 50% by volume. Place the culture at 37°C for static culture for 2 days, add 4mM veratrol, continue the culture for 3, 10, and 15 days respectively, and filter the culture to obtain crude enzyme solution;

[0043] The preparation method of the laccase enzyme production medium is as follows: add 0.1g bran per 100ml Kirk nitrogen-limited liquid medium, and sterilize at 125°C for 10min.

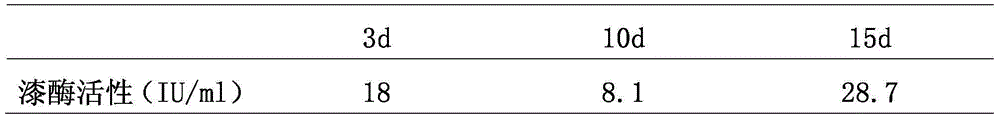

[0044] C. Determination of laccase enzyme activity, the results are shown in Table 2, and the 15d laccase crude enzyme solution with the highest enzyme activity w...

Embodiment 3

[0048] Example 3 Preparation of laccase LacP derived from Pleurotus pachyrhiza:

[0049] A. Draw the inoculation block from the Pleurotus spp. culture, inoculate it into 100ml of potato liquid seed medium, place it on a shaker, shake it at a speed of 150r / min for 4 days, and obtain a liquid strain at a temperature of 28°C;

[0050] B. Insert the prepared liquid strain into the laccase enzyme production medium with an inoculum size of 20% by volume. After the culture was placed at 28°C for 4 days, 10mM veratrol was added, and the culture was continued for 3, 10, and 15 days respectively, and the culture was filtered to obtain a crude enzyme solution;

[0051] The preparation method of the laccase enzyme production medium is as follows: add 2g bran per 100ml Kirk nitrogen-limited liquid medium, and sterilize at 121°C for 30min.

[0052] C. Determination of laccase enzyme activity, the results are shown in Table 3, select the 10d laccase crude enzyme solution with the highest en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com