Recovery process of polyurethane waste

A polyurethane waste, thermoplastic polyurethane technology, applied in the field of polyurethane, can solve the problems of human health hazards, unsatisfactory degradation efficiency, waste of reusable resources, etc., to improve the recovery yield and quality, reduce degradation by-products, and effectively recover. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

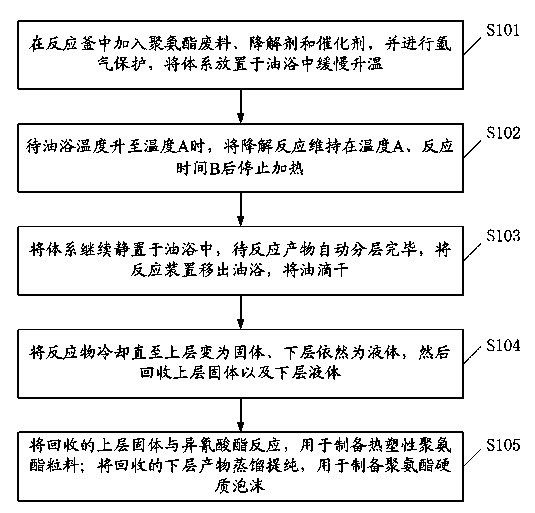

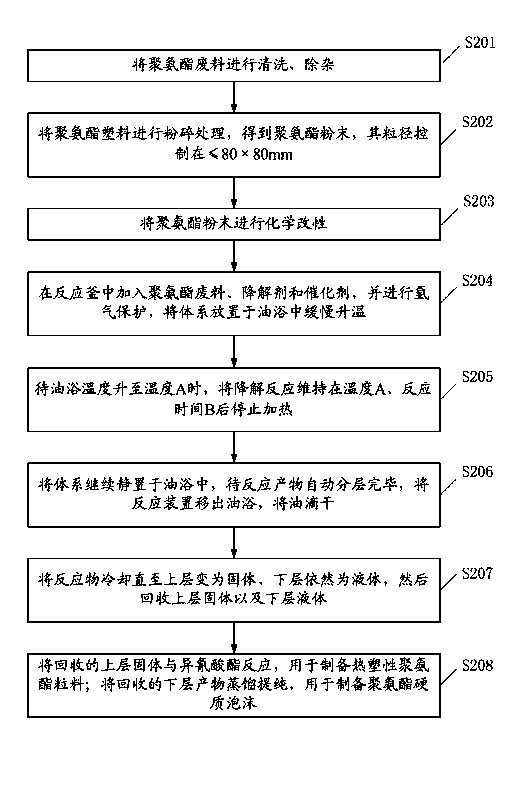

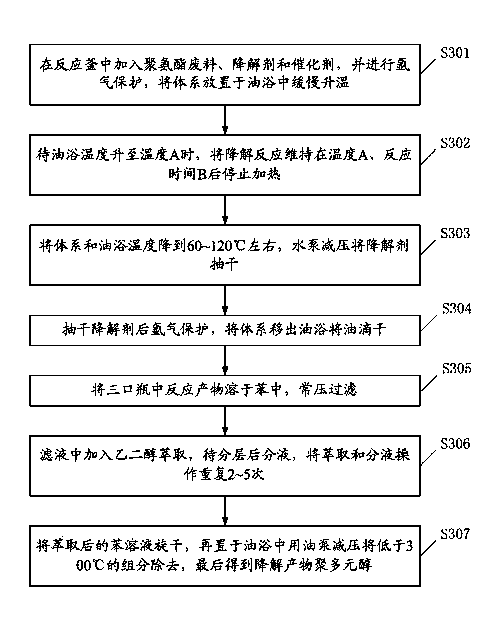

Method used

Image

Examples

Embodiment 1

[0130] Example 1: The mixture of ethylene glycol (EG), diethylene glycol (DEG) and ethylene glycol (EG), diethylene glycol (DEG) degrades thermoplastic polyurethane elastomer (TPU)

[0131] Add 30.0 g of degradation agent, 15 g of thermoplastic polyurethane elastomer (TPU) and 0.2 g of lithium acetate (LiAc) to a 50 mL three-necked flask, and then install a reflux condenser, insert a thermometer, put in a stirrer, and protect with argon , Place the system in an oil bath and slowly heat up. When the temperature of the oil bath reaches about 220°C and the reaction temperature in the three-necked flask is about 215°C, the degradation reaction is maintained at this temperature. After 3 hours of reaction, the heating is stopped, and the system continues to stand in the oil bath. After the layer is completed, the reaction device is removed from the oil bath, and the oil is dripped dry. Put the three-necked flask containing the reactants in the refrigerator, and cool to about 15°C. The...

Embodiment 2

[0137] Example 2: The mixture of diethylene glycol, ethanolamine, diethylene glycol and ethanolamine degrades thermoplastic polyurethane elastomer (TPU)

[0138] Add 30.0g of degradation agent, 15g of thermoplastic polyurethane elastomer (TPU) and 0.2g of lithium acetate (LiAc) to a 50mL three-necked flask, then install a reflux condenser, insert a thermometer, put in a stir bar, and protect it with argon. Place the system in an oil bath and slowly heat up. Control the temperature of the oil bath at the designed temperature, stop heating after 3 hours of reaction, and keep the system in the oil bath. After the reaction product is automatically stratified, the reaction device is removed from the oil bath and the oil is dripped dry. Put the three-necked flask containing the reactants in the refrigerator, and cool to about 15°C. The upper layer becomes solid, and the lower layer is still liquid. Pour out the lower layer and recover the upper solid. The lower layer is a mixture of ...

Embodiment 3

[0143] Example 3. Ternary mixed degradation agent of propylene glycol, dipropylene glycol and ethanolamine degrades thermoplastic polyurethane elastomer (TPU)

[0144] Add 30.0g of degradation agent, 15g of thermoplastic polyurethane elastomer (TPU) and 0.2g of lithium acetate (LiAc) to a 50mL three-necked flask, then install a reflux condenser, insert a thermometer, put in a stir bar, and protect it with argon. Place the system in an oil bath and slowly heat up. Control the temperature of the oil bath at the designed temperature, stop heating after 3 hours of reaction, and keep the system in the oil bath. After the reaction product is automatically stratified, the reaction device is removed from the oil bath and the oil is dripped dry. Put the three-necked flask containing the reactants in the refrigerator, and cool to about 15°C. The upper layer becomes solid, and the lower layer is still liquid. Pour out the lower layer and recover the upper solid. The lower layer is a mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com