Feedback type organic waste matter biological fermentation device

A technology of organic waste and biological fermentation, which is applied in the fields of organic fertilizers, fertilization devices, preparation of organic fertilizers, etc., can solve the problems of difficulty in maintaining the temperature of the reactor, low processing efficiency, large area/volume, etc., and achieves additional output. High value, no secondary pollution, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

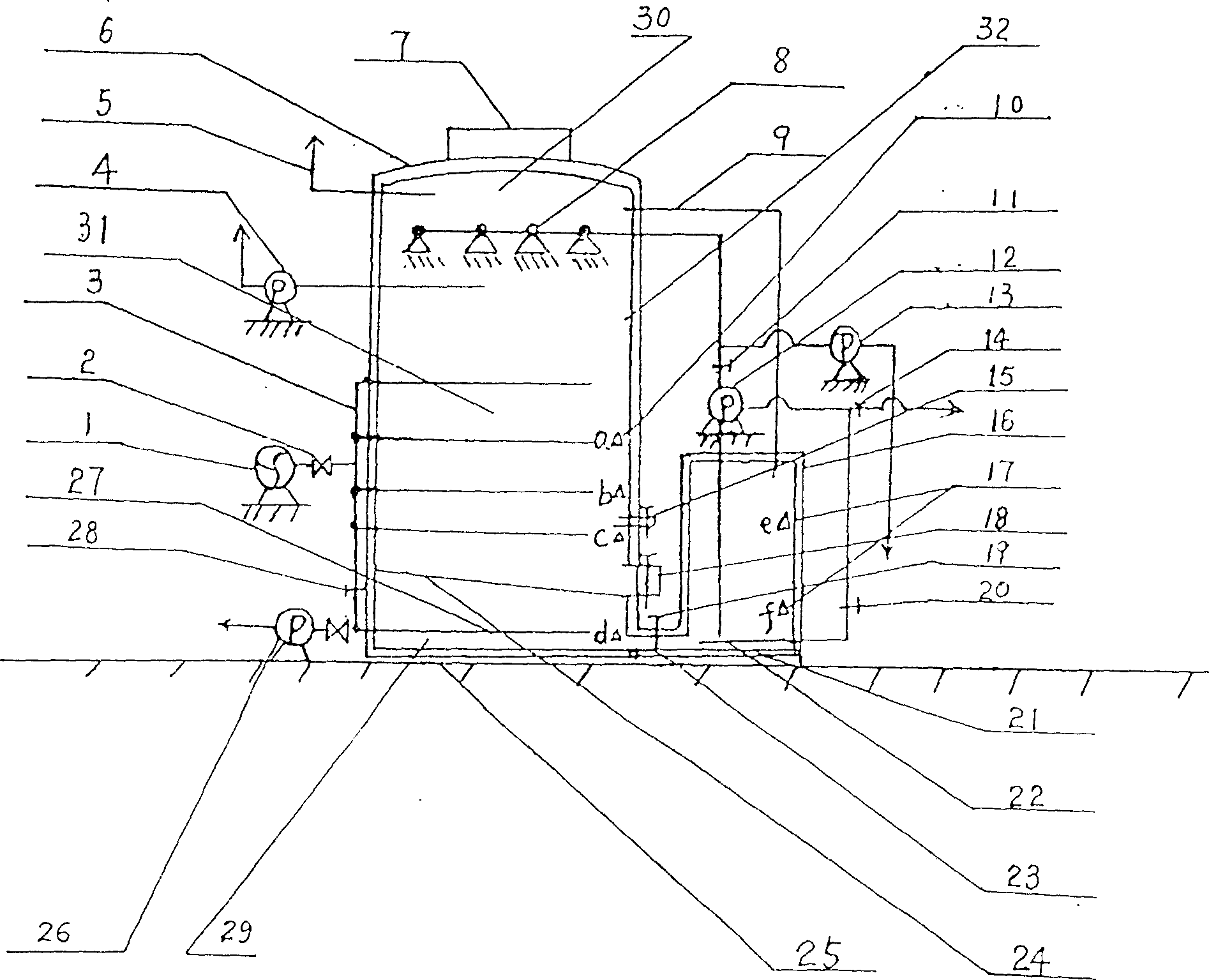

[0020] Such as figure 1 As shown, the present invention includes a reaction vessel 32, the upper end of the reaction vessel 32 is provided with a feed inlet 7, and a solid-liquid separation grid 24 is provided in the reactor, and the solid-liquid separation grid 24 separates the inside of the reactor 32 up and down. Separated into a reaction chamber and a liquid collection chamber 29, the upper part of the reaction chamber is an air chamber area 30, and the lower part is a reaction area 31. An aeration air distribution pipe 3 is provided at the upper reaction area of the solid-liquid separation grid 24, and in the air chamber area Below the 30 is provided with the spray head 8 for regulating the circulation of the bacterial liquid, and outside the reaction vessel is provided with a buffer storage tank 16 for the return flow of the bacterial liquid. The buffer storage tank 16 communicates with the bacteria liquid circulation regulating spray head 8 through the bacterial liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com