Method for degrading enteromorpha polysaccharide

A technology for the degradation reaction of E. enterica polysaccharide, applied in chemical instruments and methods, oligosaccharides, sugar derivatives, etc., can solve the problems of uneven degradation products, polysaccharide structure damage, slow polysaccharide rate, etc., and the time required to achieve is short , lower molecular weight, fast reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

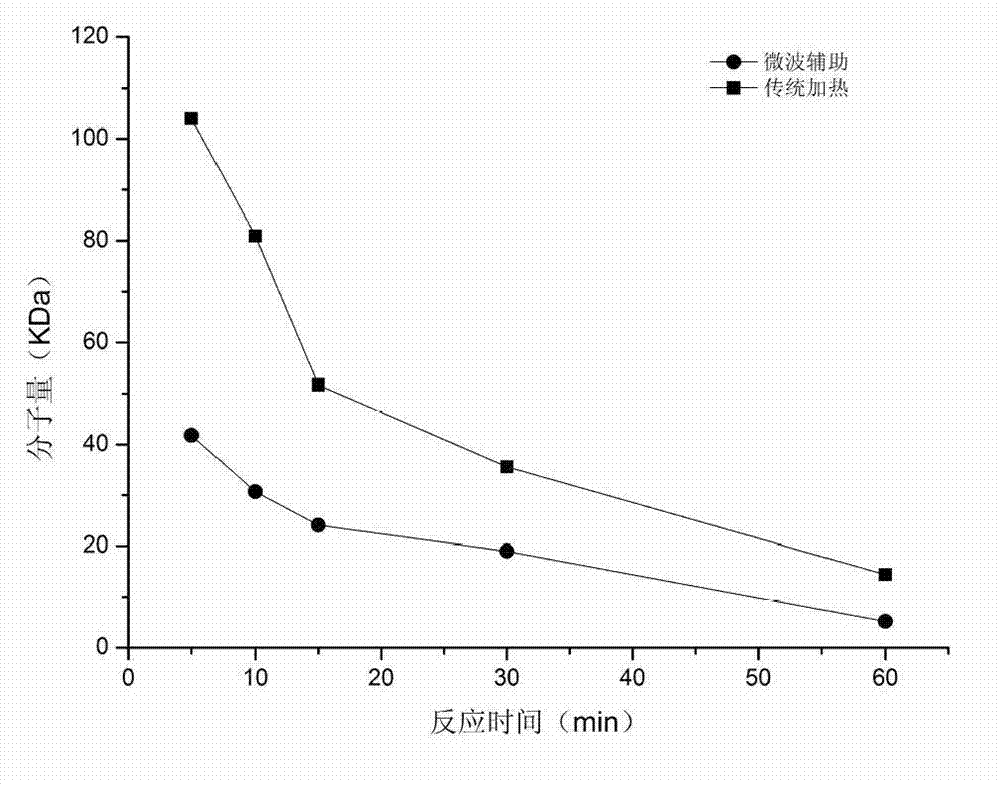

[0025] Dissolve 0.5g of high-molecular-weight Enteromorpha polysaccharide (>1500KDa) in 50ml of distilled water, add 4.2ml of concentrated hydrochloric acid and 1.5ml of 30% (mass fraction) hydrogen peroxide to the Enteromorpha polysaccharide solution, and then microwave at 70 ℃, degraded for 5-60min, according to different degradation times to obtain low-molecular-weight Enteromorpha polysaccharides and oligosaccharides; the molecular weights of different low-molecular-weight Enteromorpha polysaccharides and oligosaccharides obtained were determined by gel exclusion chromatography (see figure 1 ).

[0026] At the same time, dissolve 0.5g of high-molecular-weight Enteromorpha polysaccharide (>1500KDa) in 50ml of distilled water, add 4.2ml of concentrated hydrochloric acid and 1.5ml of 30% (mass fraction) hydrogen peroxide to the solution of Enteromorpha polysaccharide, and then adopt the traditional heating method to process Enteromorpha For the degradation of polysaccharides,...

Embodiment 2

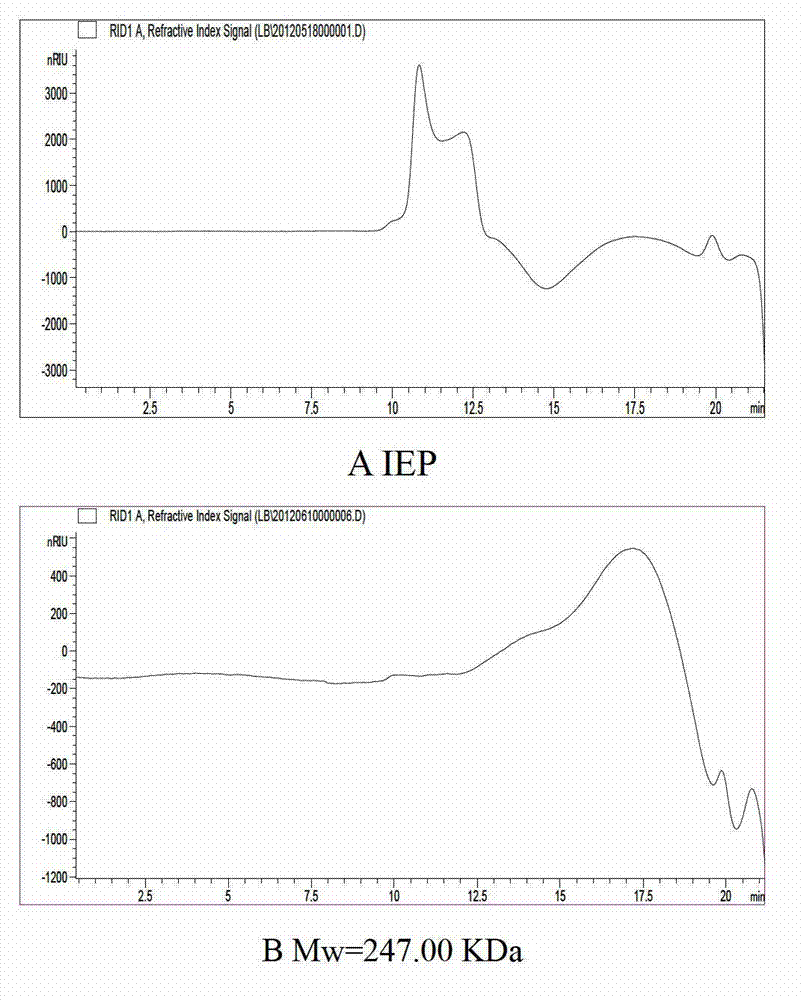

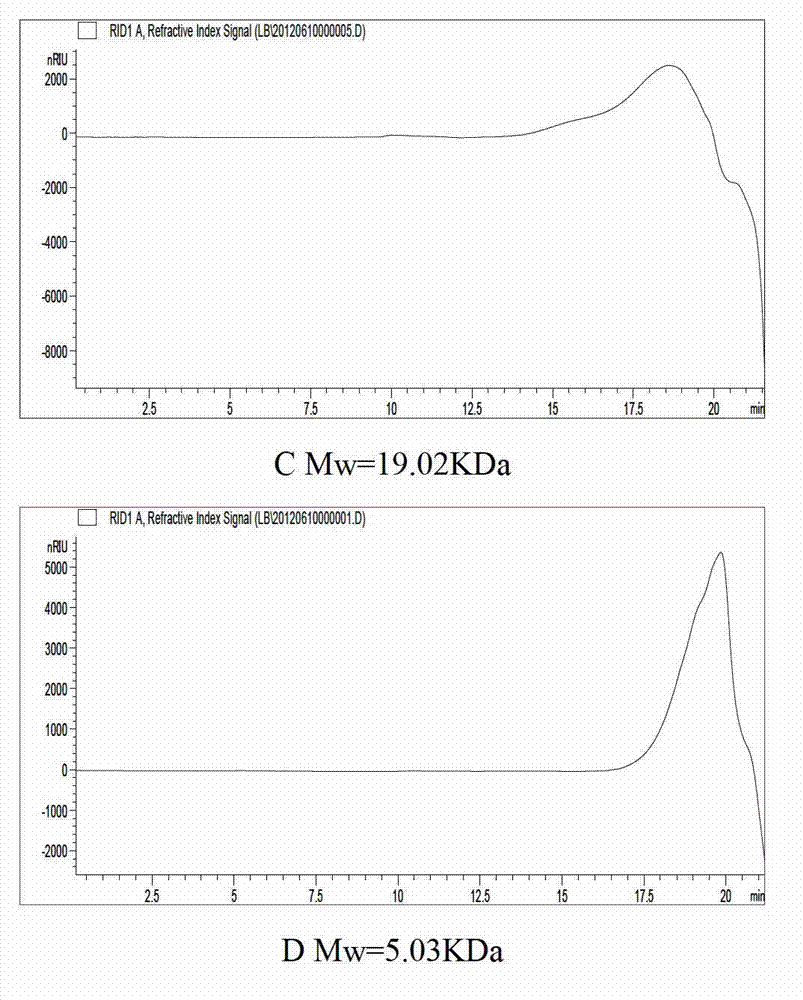

[0029] Dissolve 0.5g of high-molecular-weight Enteromorpha polysaccharide (>1500KDa) in 50ml of distilled water, add 4.2ml of concentrated hydrochloric acid and 1.5ml of hydrogen peroxide with a mass fraction of 30% to the solution of Enteromorpha polysaccharide, and degrade it for 15 minutes at a microwave power of 600W and a reaction temperature of 60°C After the reaction, the solution was neutralized to neutral with NaOH (2mol / L), concentrated by dialysis, adding 4 times the volume of 95% ethanol for precipitation, and then centrifuged at 3000r / min to collect the precipitate, freeze-dried to obtain low Molecular weight of Enteromorpha polysaccharides. The obtained product utilizes gel exclusion chromatography to measure its molecular weight to be 247.0KDa ( figure 2 shown), its chemical composition is shown in Table 1, and the infrared spectrum of the degradation product is compared with the infrared spectrum of the raw material Enteromorpha polysaccharide ( image 3 show...

Embodiment 3

[0031] Dissolve 0.5g of high-molecular-weight Enteromorpha polysaccharide (>1500KDa) in 50ml of distilled water, add 4.2ml of concentrated hydrochloric acid and 1.5ml of 30% hydrogen peroxide to the Enteromorpha polysaccharide solution, and degrade it at a microwave power of 600W and a reaction temperature of 70°C After 30 minutes, neutralize the reacted solution with lye NaOH (2mol / L) to neutrality, concentrate by dialysis, add 4 times the volume of the concentrate to precipitate with 95% ethanol, then centrifuge at a speed of 3000r / min to collect the precipitate, and freeze-dry it. Enteromorpha polysaccharides with low molecular weight were obtained. The resulting product was determined to have a molecular weight of 19.02KDa ( figure 2 shown), its chemical composition is shown in Table 1, and the infrared spectrum of the degradation product is compared with the infrared spectrum of the original Enteromorpha polysaccharide raw material ( image 3 Shown) found the characteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com