Water resistant soy protein adhesive for wood processing and preparation method thereof

A soybean protein glue and soybean protein technology, which is applied in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., can solve the problems of poor water resistance and achieve the effects of good water resistance, low viscosity and high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

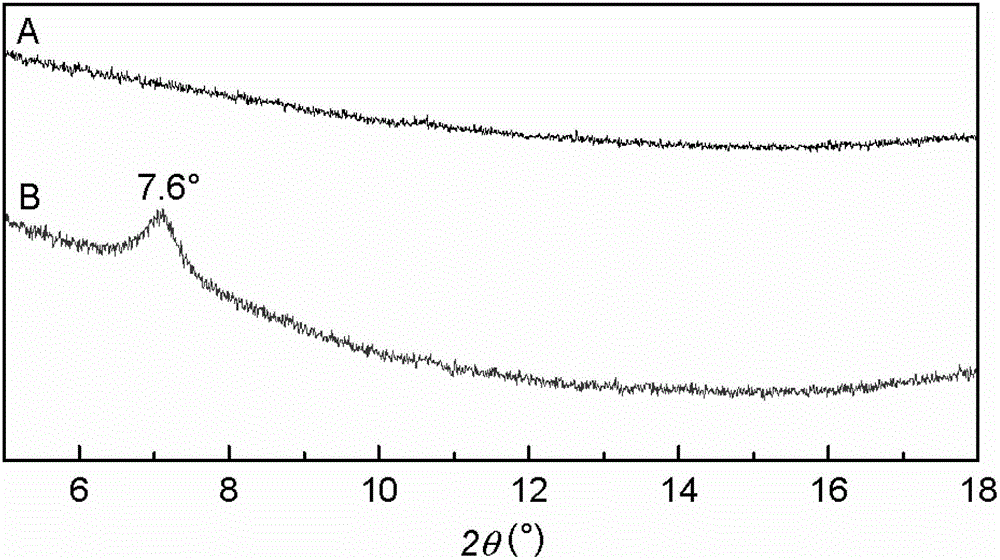

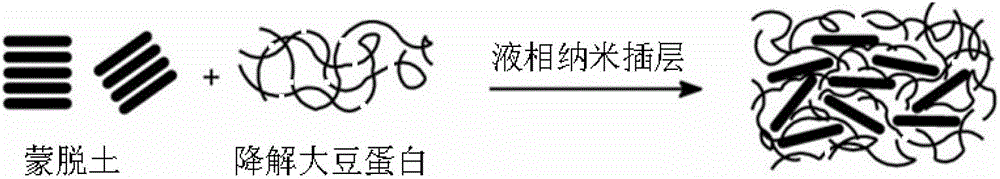

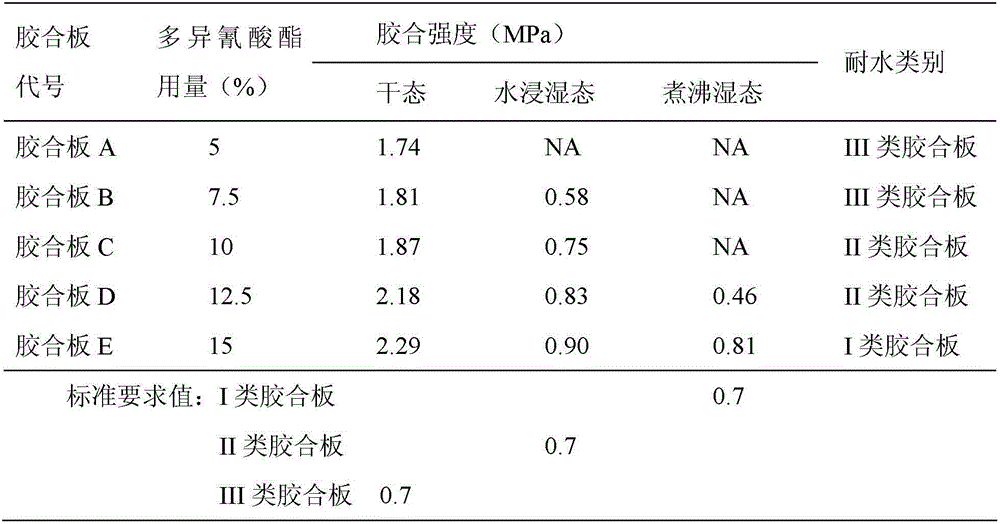

[0019] Specific Embodiment 1: In this embodiment, the water-resistant soybean protein adhesive for wood processing is degraded by 60-80 parts by weight of defatted soybean protein powder or soybean protein isolate, 6-10 parts of strong alkali and 95 parts of water. , use concentrated acid to adjust the pH value to 6.5-7.5, then add 0.3-3 parts of montmorillonite, and finally add 8-30 parts of polymethylene polyphenyl polyisocyanate and mix well.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment is different from Embodiment 1 in that the strong base is sodium hydroxide or potassium hydroxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the concentrated acid is one or both of concentrated phosphoric acid with a mass concentration of 80-85% and formic acid with a mass concentration of 85-90%. Mixtures of any composition. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com