Preparation method of modified lignin absorbent for absorbing TNT (Trinitrotoluene)

A technology of lignin and adsorbent, applied in the field of preparation of lignin derivatives, can solve the problems of difficult post-processing, low reuse rate, damage to the blood circulation system and nervous system, etc., achieves high adsorption selective adsorption capacity, overcomes the Poor adsorption selectivity and the effect of saving oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

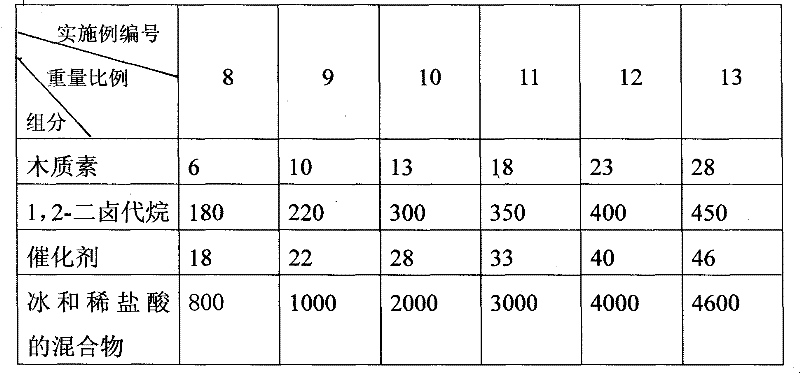

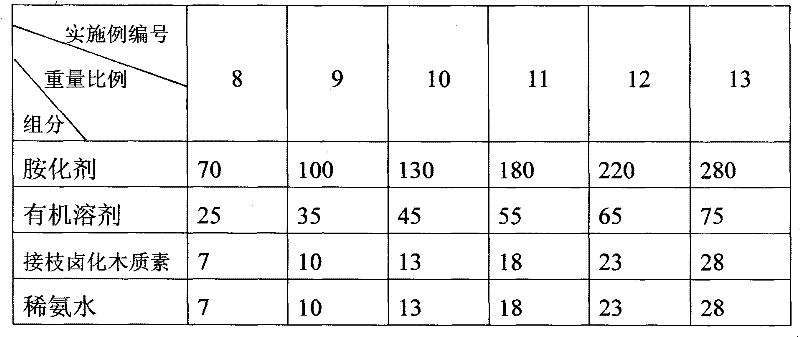

[0026] Add 10g of dry lignin to 300g of 1,2-dichloroethane, heat and stir in a water bath at 65°C, add 20g of anhydrous AlCl 3 , 1.5h and then add 10g of anhydrous AlCl 3 (anhydrous aluminum chloride), after another 1.5h, add 5g of anhydrous AlCl 3 , and then heated for 2.5h (total time 5.5h); the reacted mixture was quickly poured into a mixture of ice and 7% dilute hydrochloric acid (both weight ratio 1:4), stirred, and filtered with a strainer; Dilute hydrochloric acid and water to remove AlCl 3 , dried at 90°C for 24 hours; the dried solid was taken out, washed with alcohol until the filtrate was colorless, and dried at 65°C for 12 hours to obtain chlorinated lignin. Add 150g of ethylenediamine to 50g of N,N-dimethylformamide, then add 7g of chlorinated lignin, and after bathing in water at 80°C for 6 hours, filter the reacted mixture, wash it successively with dilute ammonia water and water, and finally wash it with Wash with acetone until the filtrate is colorless, an...

Embodiment 2

[0029]Add 5g of dry lignin to 200g of 1,2-dichloroethane, heat and stir in a water bath at 70°C, add 15g of anhydrous AlCl 3 , 2h and then add 10g of anhydrous AlCl 3 , and then heated for 2.5h (total time 4.5h). The reacted mixture was quickly poured into a mixture of ice and 5% dilute hydrochloric acid (the weight ratio of the two was 1:3), stirred, and filtered with a filter; 3 , dried at 95°C for 24 hours; the dried solid was taken out, washed with acetone until the filtrate was colorless, and dried at 65°C for 10 hours to obtain chlorinated lignin. Add 100g of ethylenediamine to 20g of N,N-dimethylformamide, heat and stir in a water bath at 90°C, then add 3g of chlorinated lignin, and after 5 hours in a water bath at 90°C, filter the reacted mixture, and wash with dilute Wash with ammonia water and water, and finally wash with acetone until the filtrate is colorless, and dry at 100° C. for 12 hours to obtain a brown modified lignin adsorbent that can be used to adsorb T...

Embodiment 3

[0032] Add 10g of dry lignin to 300g of 1,2-dibromoethane, heat and stir in a water bath at 60°C, add 20g of anhydrous AlCl 3 , 2h and then add 10g of anhydrous AlCl 3 , after another 2h, add 5g of anhydrous AlCl 3 , and then heated for 3h (total time 7h); the reacted mixture was quickly poured into a mixture of ice and 3% dilute hydrochloric acid (both weight ratio 1:2), stirred, and filtered with a filter screen; and water to remove AlCl 3 , dried at 100°C for 18 hours; the dried solid was taken out, washed with alcohol until the filtrate was colorless, and dried at 65°C for 12 hours to obtain brominated lignin. Add 200g of ethylenediamine to 50g of N,N-dimethylformamide, then add 7g of brominated lignin, and after 8 hours in a water bath at 70°C, filter the reacted mixture, wash it successively with dilute ammonia water and water, and finally wash it with Wash with acetone until the filtrate is colorless, and dry at 60°C for 24 hours to obtain a brown modified lignin ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com