Technique for biological treatment of mine acidic wastewater

A technology for acid mine wastewater and biological treatment, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve good treatment effect, no secondary pollution, and reduce wastewater treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

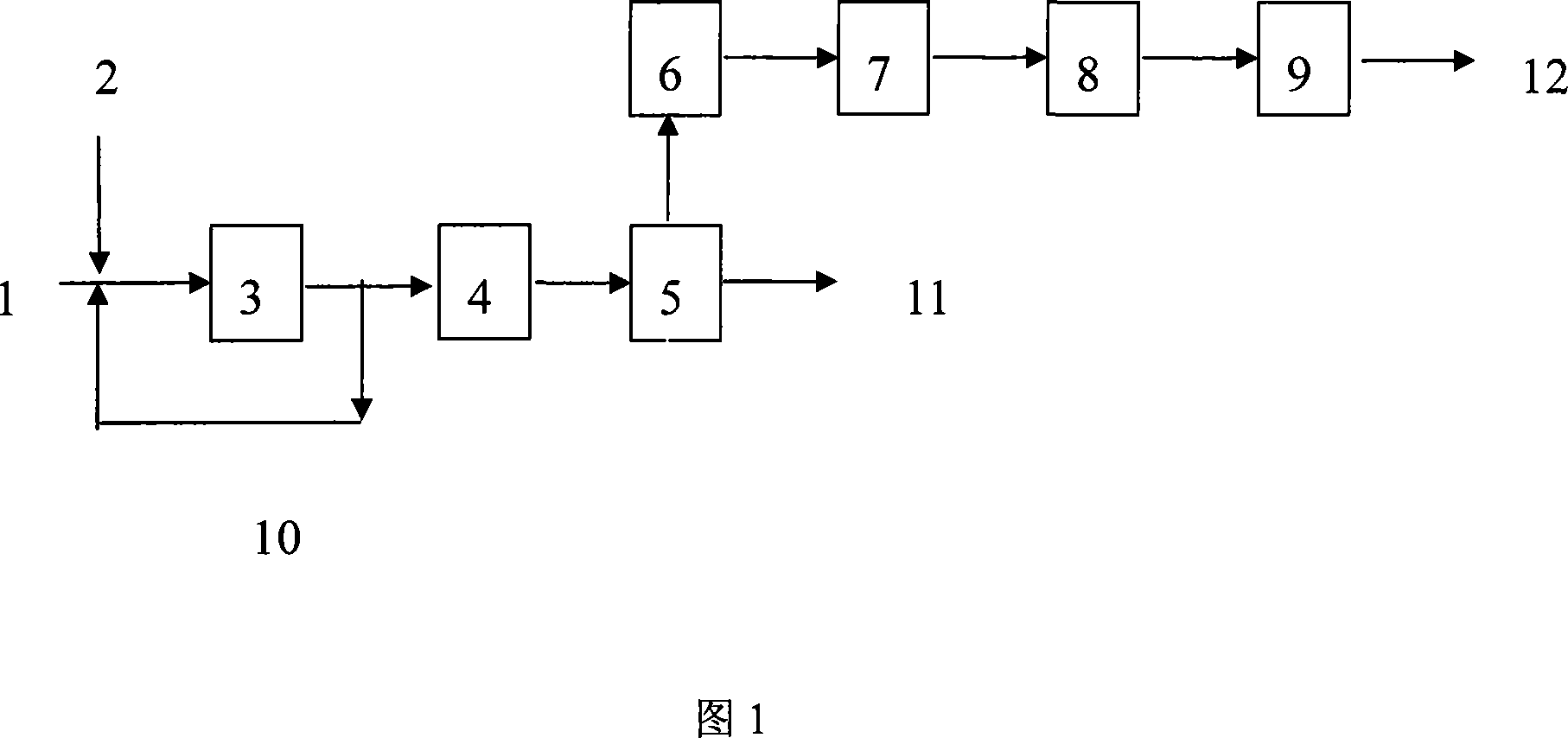

Method used

Image

Examples

Embodiment approach 1

[0040] Embodiment 1, sulfate bioreduction reactor, the sulfate load is 7.0kgSO 4 2 / m 3 d, the temperature is 35°C, COD / SO 4 2- The value is 1.2, the influent pH value is 6.5, the rising flow rate of the anaerobic expanded granular sludge bed reactor EGSB v up is 3.0m / h, the reflux ratio is 80:1, and the hydraulic retention time HRT is 0.2d; the reflux ratio of the anaerobic biofilter AF is 20:1, and the HRT is 0.25d; the anaerobic baffle reactor ABR, HRT is 0.2d; anaerobic fluidized bed reactor AFBR, HRT is 0.02d; colorless sulfur bacteria CSB biological oxidation of S 2- Reactor, pH 8.0, temperature 15°C, sulfide loading 12.0kg / m 3 d, DO≈5.5mg / L in the reactor; slow sand filter, with a filtration rate of 0.1m / h and a filtration cycle of 25d, intercepting elemental sulfur S in the sand layer of the surface layer 6cm; the particle size of the sand filter layer is 1.2mm , thickness 25cm; supporting layer sand particle size from bottom to top 5.0mm, 2.5mm, 1.2mm, each laye...

Embodiment approach 2

[0041] Embodiment 2, sulfate bioreduction reactor, the sulfate load is 4.0kgSO 4 2 / m 3 d, anaerobic expanded granular sludge bed reactor EGSB, HRT is 0.5d; anaerobic biofilter AF, HRT is 0.75d; anaerobic baffle reactor ABR, HRT is 0.6d; anaerobic fluidized bed Reactor AFBR, HRT is 0.16d, other is the same as Embodiment 1.

Embodiment approach 3

[0042] Embodiment 3, sulfate bioreduction reactor, the sulfate load is 1.0kgSO 4 2 / m 3 d, anaerobic expanded granular sludge bed reactor EGSB, HRT is 0.85d; anaerobic biological filter AF, HRT is 1.25d; anaerobic baffle reactor ABR, HRT is 1.0d; anaerobic fluidized bed Reactor AFBR, HRT is 0.3d, others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com