Preparation method of modified lignin absorbent for absorbing TNT (Trinitrotoluene)

A technology of lignin and adsorbent, which is applied in the field of preparation of lignin derivatives, can solve the problems of post-processing difficulties, low reutilization rate, difficult to handle, etc., achieve high adsorption selective adsorption capacity, overcome poor adsorption selectivity, good The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

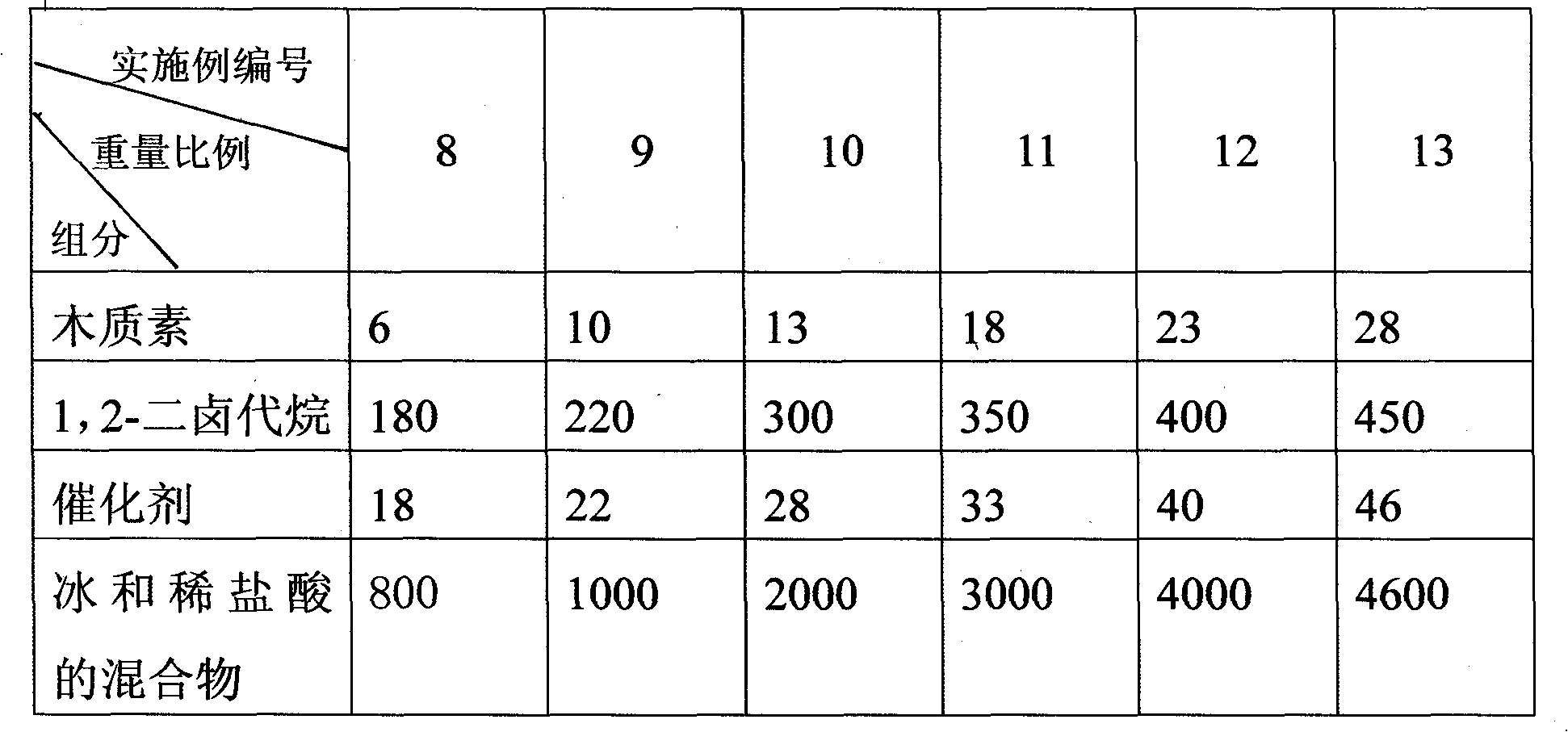

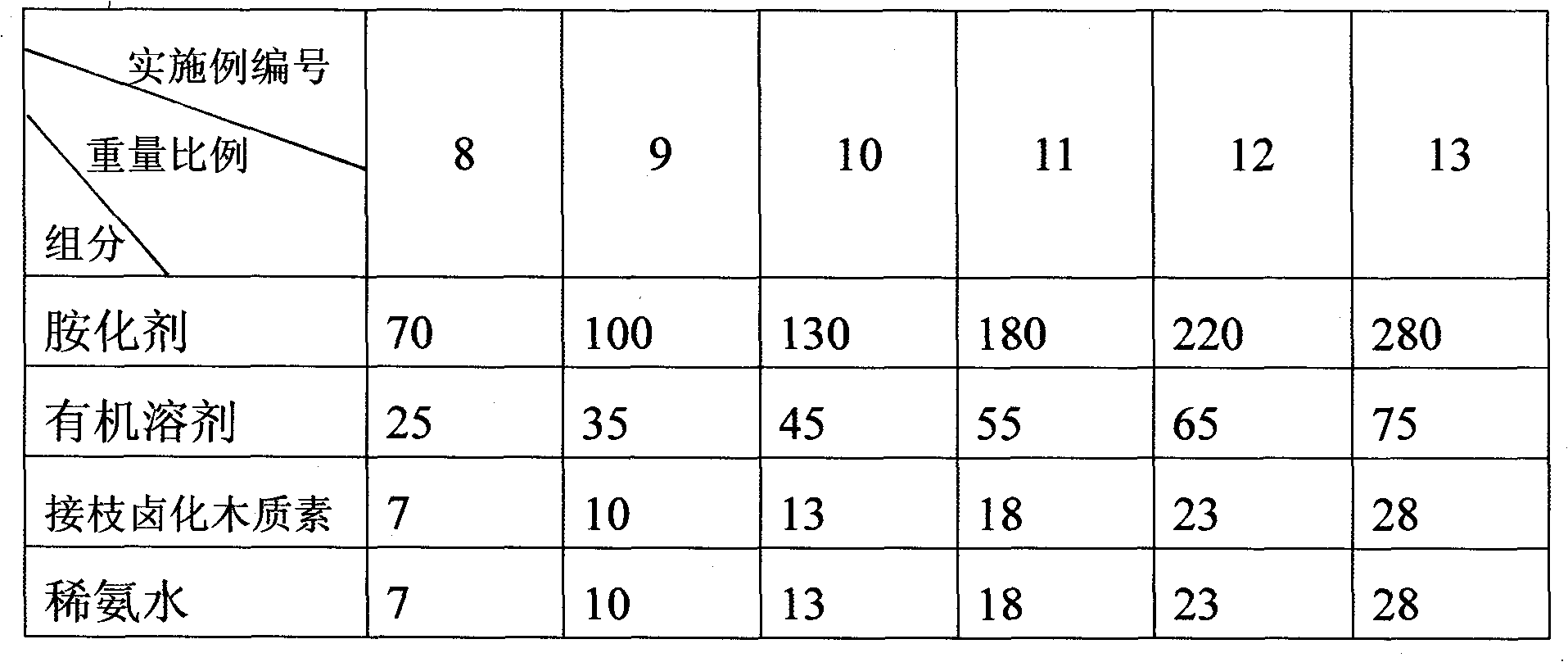

[0026] Add 10g of dry lignin to 300g of 1,2-dichloroethane, heat and stir in a water bath at 65°C, add 20g of anhydrous AlCl 3 , 1.5h and then add 10g of anhydrous AlCl 3 (anhydrous aluminum chloride), after another 1.5h, add 5g of anhydrous AlCl 3 , and then heated for 2.5h (total time 5.5h); the reacted mixture was quickly poured into a mixture of ice and 7% dilute hydrochloric acid (both weight ratio 1:4), stirred, and filtered with a strainer; Dilute hydrochloric acid and water to remove AlCl 3 , dried at 90°C for 24 hours; the dried solid was taken out, washed with alcohol until the filtrate was colorless, and dried at 65°C for 12 hours to obtain chlorinated lignin. Add 150g of ethylenediamine to 50g of N,N-dimethylformamide, then add 7g of chlorinated lignin, and after bathing in water at 80°C for 6 hours, filter the reacted mixture, wash it successively with dilute ammonia water and water, and finally wash it with Wash with acetone until the filtrate is colorless, an...

Embodiment 2

[0029]Add 5g of dry lignin to 200g of 1,2-dichloroethane, heat and stir in a water bath at 70°C, add 15g of anhydrous AlCl 3 , 2h and then add 10g of anhydrous AlCl 3 , and then heated for 2.5h (total time 4.5h). The reacted mixture was quickly poured into a mixture of ice and 5% dilute hydrochloric acid (the weight ratio of the two was 1:3), stirred, and filtered with a filter; 3 , dried at 95°C for 24 hours; the dried solid was taken out, washed with acetone until the filtrate was colorless, and dried at 65°C for 10 hours to obtain chlorinated lignin. Add 100g of ethylenediamine to 20g of N,N-dimethylformamide, heat and stir in a water bath at 90°C, then add 3g of chlorinated lignin, and after 5 hours in a water bath at 90°C, filter the reacted mixture, and wash with dilute Wash with ammonia water and water, and finally wash with acetone until the filtrate is colorless, and dry at 100° C. for 12 hours to obtain a brown modified lignin adsorbent that can be used to adsorb T...

Embodiment 3

[0032] Add 10g of dry lignin to 300g of 1,2-dibromoethane, heat and stir in a water bath at 60°C, add 20g of anhydrous AlCl 3 , 2h and then add 10g of anhydrous AlCl 3 , after another 2h, add 5g of anhydrous AlCl 3 , and then heated for 3h (total time 7h); the reacted mixture was quickly poured into a mixture of ice and 3% dilute hydrochloric acid (both weight ratio 1:2), stirred, and filtered with a filter screen; and water to remove AlCl 3 , dried at 100°C for 18 hours; the dried solid was taken out, washed with alcohol until the filtrate was colorless, and dried at 65°C for 12 hours to obtain brominated lignin. Add 200g of ethylenediamine to 50g of N,N-dimethylformamide, then add 7g of brominated lignin, and after 8 hours in a water bath at 70°C, filter the reacted mixture, wash it successively with dilute ammonia water and water, and finally wash it with Wash with acetone until the filtrate is colorless, and dry at 60°C for 24 hours to obtain a brown modified lignin ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com