Method for realizing nuclear reactor load tracking

A nuclear reactor and load tracking technology, applied in the control of nuclear reactions, reactors, nuclear engineering, etc., can solve the problems of increased load of the control rod drive mechanism, uneven fuel burnup, and high control rod absorber burnup, etc. Effects of Wastewater Treatment Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

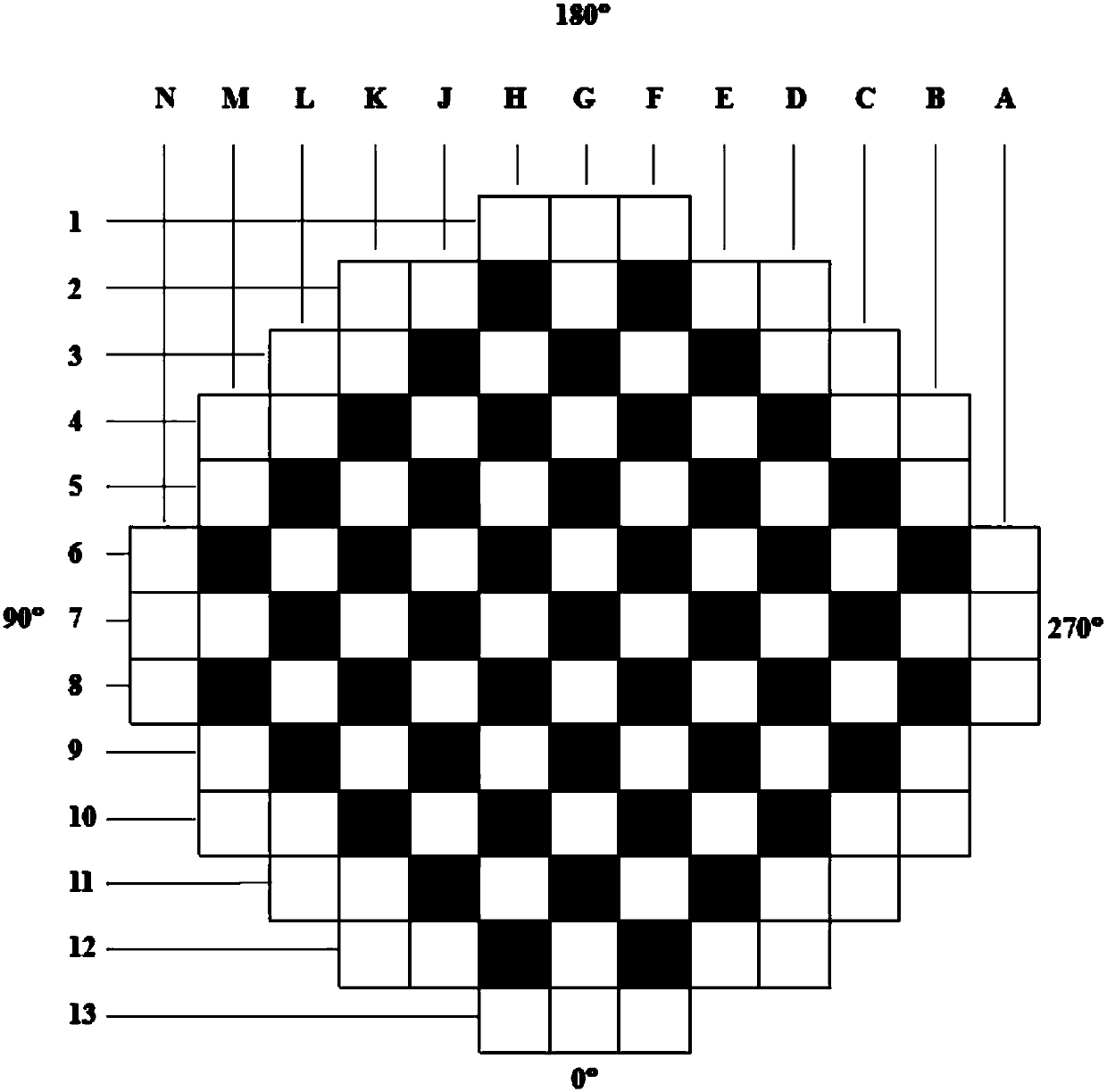

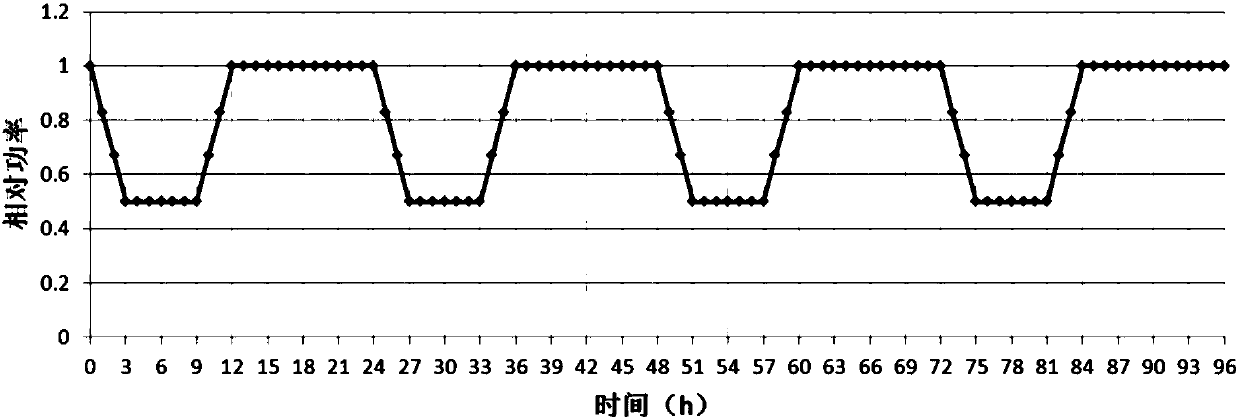

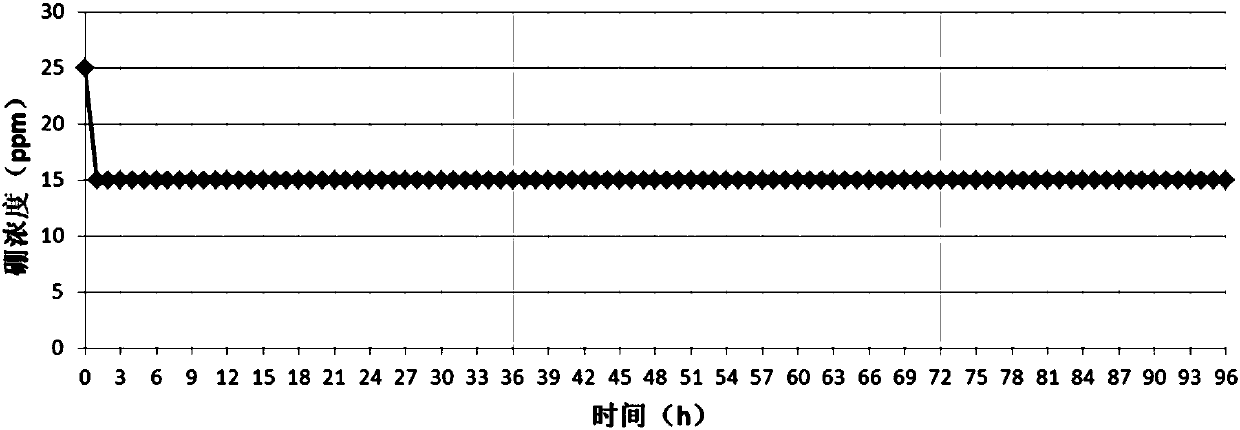

[0056] Such as Figure 1 to Figure 8 As shown, the present embodiment provides a kind of specific implementation scheme based on the realization method of a kind of nuclear reactor load tracking described above. In this implementation scheme, the corresponding nuclear reactor is a double-loop pressurized water reactor, and the core consists of 121 fuel Component composition. figure 1 A typical layout of control rods in the core is given. The core uses 45 bundles of control rods, of which 33 bundles are black body control rods and 12 bundles are gray body control rods. The shutdown rod group is S rod group, which is used to ensure that the reactor has sufficient shutdown margin at any power level. The length of control rods and shutdown rods are both 225 steps. The control rod group includes K rod group and T rod group. During baseload operation, only the K-rod group is inserted into the core to control the average core coolant temperature and axial power offset. During the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com